Energy storage compartment battery

What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage system (BESS) is

Recommendations for energy storage compartment used in renewable energy

Aug 1, 2022 · The growth in renewable energy (RE) projects showed the importance of utility electrical energy storage. High-capacity batteries are used in most RE projects to store energy

Energy storage system battery compartment heat

To verify the effectiveness of the cooling function of the liquid cooled heat dissipation structure designed for vehicle energy storage batteries, it was applied to battery modules to analyze

Battery Energy Storage System | SpringerLink

Jan 1, 2013 · This chapter discusses the various technical components of battery energy storage systems for utility-scale energy storage and how these technical components are interrelated.

Unveiling the Industrial and Commercial Liquid-Cooled Energy Storage

Mar 7, 2025 · In various industrial and commercial settings, more and more enterprises are adopting energy storage systems—devices often referred to as "industrial power banks."

Energy storage battery compartment structure

energy storage technologies that currently are, or could be, undergoing research and development that could directly or indirectly benefit fossil thermal energy power systems. o

Energy storage battery compartment foundation

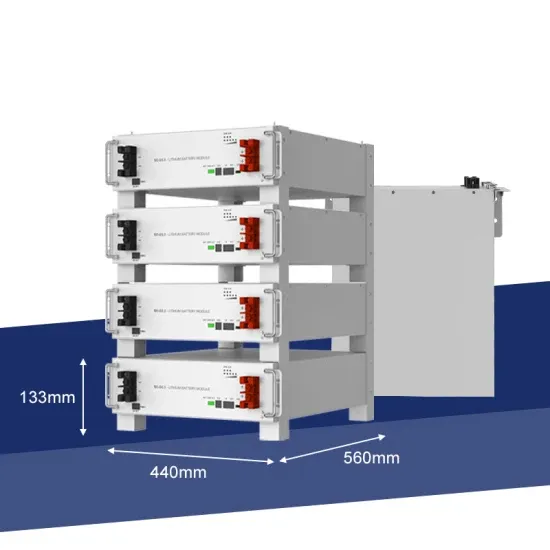

The energy storage battery compartment consists of several integral components that work together to ensure efficient energy storage and management. 1. Battery cells, 2. Battery

Energy Storage Station Structure Design: Building the Power

Mar 29, 2023 · Modern energy storage station design isn''t just about stacking batteries. It''s a symphony of six core elements [5]: 1. Battery Systems: The Heart (But Not the Brain) Lithium

Battery Pack and Underbody: Integration in the

Apr 23, 2023 · The integration of the battery pack''s housing structure and the vehicle floor leads to a sort of sandwich structure that could have beneficial

Key Design Principles for Battery Pack Structures in Energy Storage

Nov 25, 2024 · The structural design of battery packs in energy storage systems (ESS) is crucial for ensuring safety, performance, cost-effectiveness, and adaptability across various

Key Design Principles for Battery Pack Structures in Energy Storage

Nov 25, 2024 · Explore essential design guidelines for battery pack structures in energy storage systems, focusing on safety, adaptability, thermal protection, and manufacturing efficiency,

Framework and Classification of Battery System

Mar 30, 2023 · In this paper, battery system architectures are methodologically derived in order to find the key type differences. In a first step, the system

【中文】一种换电式电动汽车电池仓结构 【EN】Battery

Dec 20, 2019 · According to the battery compartment structure of the battery replacing type electric automobile, provided by the invention, the battery compartment main body is arranged

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · Abstract The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the

What is the power of the energy storage battery compartment?

Sep 8, 2024 · Energy storage battery compartments play a pivotal role in the transition towards sustainable energy solutions, enabling the successful integration of renewable sources such

Fire Accident Simulation and Fire Emergency Technology

Sep 26, 2022 · In order to establish a reliable thermal runaway model of lithium battery, an updated dichotomy methodology is proposed-and used to revise the standard heat release

Recommendations for energy storage compartment used in renewable energy

Aug 1, 2022 · High-capacity batteries require a compartment that satisfies the condition needed for the best operation and battery lifetime utilization. Batteries compartment design

6 FAQs about [Energy storage battery compartment structure]

What are the different types of battery compartments?

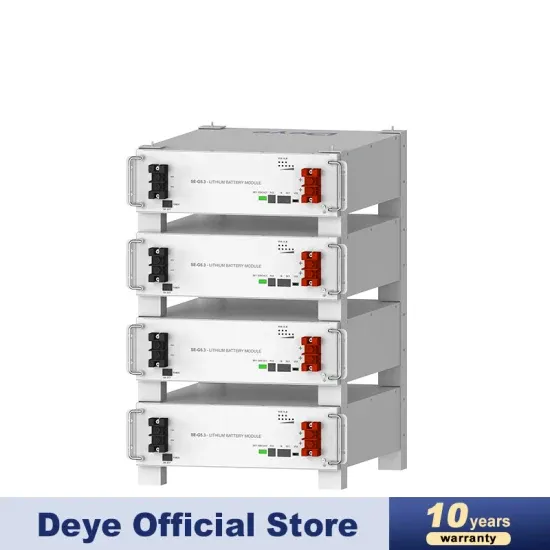

There are currently two main structures for battery compartments: containerized and commercial cabinet type. The most basic unit of an energy storage system is the battery cell, and multiple battery cells combined together form a battery module.

What is a DC side energy storage battery compartment?

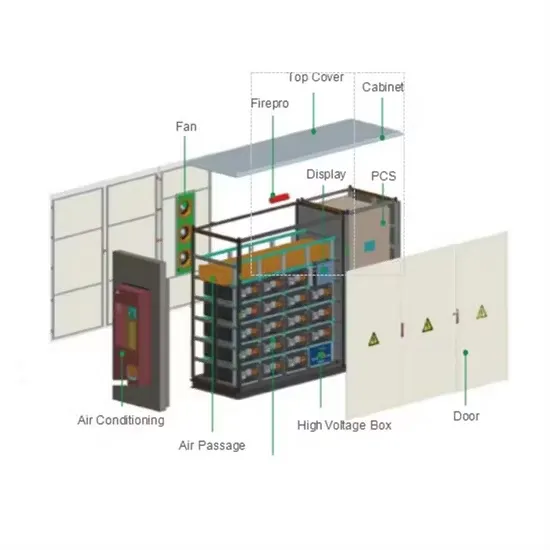

One or more battery clusters, energy management system EMS, thermal management system, fire safety system, etc., form a DC side energy storage battery compartment. Combined with bidirectional PCS, it can form an AC output energy storage battery compartment. 1 Basic structure of battery compartment

What is a battery compartment?

A battery compartment usually consists of several parts, including the cabin body, battery system, temperature control system, fire protection system, electrical system, etc. The cabin adopts a containerized design, which has good sealing and seismic resistance, and can effectively protect internal equipment from external environmental influences.

What is a battery energy storage system?

Battery energy storage systems have characteristics that are quite different from the traditional power sources that electric utilities are most familiar with. In the first instance, there is no rotating mass.

What is a battery energy storage system (BESS)?

The latter is a power application, while the former requires larger capacity (i.e., it is an energy application). A battery energy storage system (BESS) can be used independently or can be integrated into a hybrid system (e.g., with ECs) to provide both energy and power responses in a given application as diagrammatically depicted in Fig. 9.1.

What are the fire-fighting facilities used for energy storage battery compartments?

The fire-fighting facilities used for energy storage battery compartments are generally as follows: first, ventilation devices; Secondly, combustible gas detectors; Thirdly, fire extinguishers; The fourth is the fire sand box; The fifth is the fire alarm system; The sixth is the gas automatic fire extinguishing system.

Learn More

- Refrigeration system in the energy storage battery compartment

- Manila energy storage cabinet battery structure

- Energy storage gel battery structure

- What are the functions of the energy storage battery compartment

- The internal structure of the battery in the energy storage cabinet and the station cabinet

- Energy storage container battery pack structure

- A battery cabinet structure for energy storage container

- Equatorial Guinea energy storage battery prices

- Costa Rica Portable Energy Storage Battery Company

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.