Design and Construction of Solar Powered DC Fridge for

Jun 27, 2024 · Fabrication and Design of a Solar Battery-Less DC Refrigerator System for Storage of Fruits and Vegetables, International Research Journal of Modernization in

What is the power of the energy storage battery compartment?

Sep 8, 2024 · 1. The power of energy storage battery compartments can be defined as1. A critical component for renewable energy integration, 2. Enabling greater efficiency in energy usage, 3.

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Refrigerated Transport: State of the Art, Technical Issues,

Sep 1, 2022 · Vapor Compression Refrigeration (VCR) units are the most used systems (market share of 80% [1]) in refrigeration (industrial, commercial, domestic, refrigerated transport) and

Frontiers | Research and design for a storage liquid

Aug 9, 2024 · The key system structure of energy storage technology comprises an energy storage converter (PCS), a battery pack, a battery management system (BMS), an energy

Recent developments in solar-powered refrigeration systems and energy

Dec 1, 2024 · The integration of cold thermal energy storage with a solar refrigeration system (SRS) will be the next-generation alternative for battery-based backup, which has the potential

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Using solar-powered refrigeration for vaccine storage where

Dec 9, 2013 · Recognizing that the majority of equipment failure has centered on the battery system, in the last decade refrigerator manufacturers have developed second-generation solar

Improvement on energy consumption of a refrigerator within PV system

Nov 1, 2021 · The energy consumption was measured experimentally at four different temperatures from 10 °C to 40 °C to provide information on underlying energy changes due to

Research and design for a storage liquid refrigerator

Aug 7, 2024 · At present, energy storage in industrial and commercial scenarios has problems such as poor protection levels, flexible deployment, and poor battery performance. Aiming at

Research on energy saving optimization method of electric

May 1, 2022 · To extend the working time of battery of the electric refrigerated truck, the optimization method of the refrigeration system of a certain electric refrigerated truck is

High-Efficiency Refrigerator with Cold Energy Storage

Jul 5, 2023 · Objective and Outcome The objective is to develop a novel household refrigerator that uses advanced evaporators with phase change material (PCM)-based, long-duration cold

Cooling unit impact on energy and emissions of a

Nov 5, 2022 · The authors reported that 65–86 % of the emissions related to the cooling unit comes from the energy consumption needed to power the unit itself and to carry the additional

Energy Storage Refrigeration Systems: The Backbone of Modern Battery

With global battery storage capacity projected to hit 1.2 TWh by 2030 according to the 2024 Energy Storage Innovation Report, inefficient cooling isn''t just a technical hiccup—it''s a multi

Air-Cooled Thermal Management for EV Battery Packs

Jul 30, 2025 · An air-cooled battery pack design for small-scale air-cooled energy storage systems. The battery pack has a box with an internal cooling chamber that the battery module

6 FAQs about [Refrigeration system in the energy storage battery compartment]

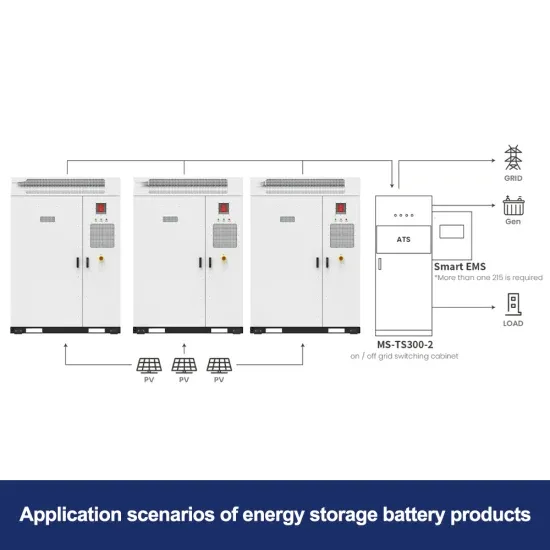

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

Can a battery energy storage system fit a closed-loop air conditioner?

A leading manufacturer of battery energy storage systems contacted Kooltronic for a thermal management solution to fit its rechargeable power system. Working collaboratively with the manufacturer, Kooltronic engineers modified a closed-loop air conditioner to fit the enclosure, cool the battery compartment, and maximize system reliability.

What are battery energy storage systems (Bess)?

As the demand for sustainable energy solutions grows, Battery Energy Storage Systems (BESS) have become crucial in managing and storing energy efficiently. This year, most storage integration manufacturers have launched 20-foot, 5MWh BESS container products.

What is a battery energy storage system?

Battery energy storage systems (BESS) ensure a steady supply of lower-cost power for commercial and residential needs, decrease our collective dependency on fossil fuels, and reduce carbon emissions for a cleaner environment.

What are the functions of the energy storage system?

The energy storage system supports functions such as grid peak shaving, frequency regulation, backup power, valley filling, demand response, emergency power support, and reactive power compensation. The 2.5MW/5.016MWh battery compartment utilizes a battery cluster with a rated voltage of 1331.2V DC and a design of 0.5C charge-discharge rate.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

Learn More

- Energy storage battery compartment AC power supply

- Energy storage battery compartment structure

- What are the functions of the energy storage battery compartment

- Maputo Energy Storage Lithium Battery Project

- Home energy storage battery 20 degrees

- Auckland New Zealand Industrial and Commercial Energy Storage Battery

- Majuro Energy Storage System Lithium Battery

- What is the process for replacing the battery energy storage system of a communication base station

- Kuwait outdoor communication battery cabinet energy storage battery website

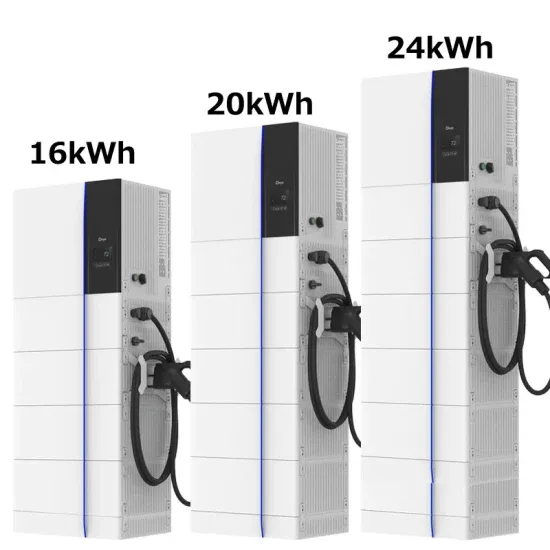

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

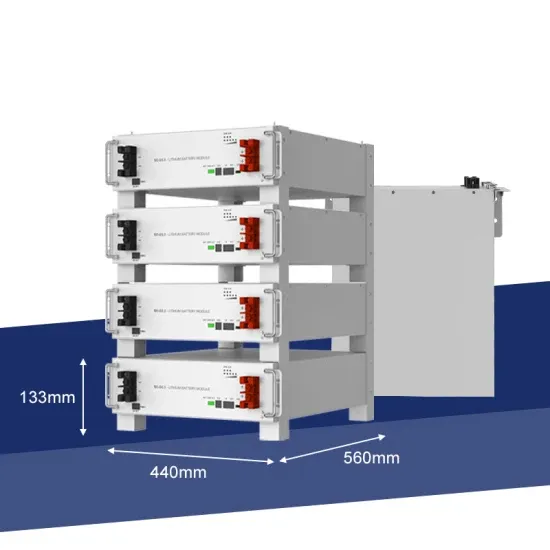

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.