A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key

DOE ESHB Chapter 7 Flywheels

Mar 17, 2022 · Flywheel systems in service today demonstrate millisecond response times, energy storage up to 700 kWh per rotor, power output of up to 500 MW per rotor, and decades

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

Long-Discharge Flywheel Versus Battery Energy Storage

Oct 18, 2019 · One of the energy storage technologies being considered for microgrid applications are flywheels, which stores energy through rotational kinetic energy. The maximum rotational

Flywheel energy storage

Jan 1, 2022 · The flywheel schematic shown in Fig. 11.1 can be considered as a system in which the flywheel rotor, defining storage, and the motor generator, defining power, are effectively

Flywheel Energy Storage Cost per kWh: Efficiency Meets

Why Flywheel Storage is Redefining Energy Economics As global industries seek cost-effective energy storage, flywheel systems emerge as game-changers with flywheel energy storage

A Trial Manufacturing of 1k Wh Flywheel with High

Sep 1, 2000 · As the high temperature superconducting magnetic bearing has the characteristics of low loss, research and developments of the flywheel with this bearing have been executed

Design, Fabrication, and Test of a 5 kWh Flywheel Energy

Jun 19, 2017 · Abstract The Boeing team has designed, fabricated, and is currently testing a 5 kWh / 100 kW Flywheel Energy Storage System (FESS) utilizing the Boeing patented high

A review of flywheel energy storage rotor materials and

Dec 25, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · The Amber Kinetics M32 flywheel is a 32 kilowatt-hour (kWh) kinetic energy storage device designed with a power rating of 8kW and a 4-hour discharge duration (Figure ES-1).

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · The core element of a flywheel consists of a rotating mass, typically axisymmetric, which stores rotary kinetic energy E according to (Equation 1) E = 1 2 I ω 2 [J], where E is the

Flywheel Energy Storage Cost per kWh: Efficiency Meets

Unlike lithium-ion batteries requiring frequent replacements, a California data center using 10MW flywheel array achieved $1,200/kWh lifecycle costs - 40% lower than conventional battery

Flywheel energy-storage-and-conversion system for

Efforts to develop a magnetically suspended solar photovoltaic flywheel energy storage unit for residential applications are discussed. A 1/10-scale prototype flywheel unit, which stores 1

A review on flywheel energy storage technology in fifty years

A single flywheel stored energy of 0.5~130 kW·h in charging or discharging with power of 0.3~3000 kW. The frontier technologies include new materials of flywheel rotor, super

Flywheel Energy Storage System with Superconducting

Oct 28, 2021 · During the five-year period, we carried out two major studies - one on the operation of a small flywheel system (built as a small-scale model) and the other on superconducting

RotorVault Energy Storage Cost Analysis and Flywheel Price

5 days ago · RotorVault Flywheel Cost-Competitive Technology RotorVault''s storage product for data center applications is the most cost-competitive solution offering both backup power for

Energy Storage Flywheel Market – PW Consulting Chemical & Energy

Jan 24, 2025 · Energy storage flywheel systems are gaining traction due to their ability to deliver rapid energy discharge, high cycle life, and minimal environmental impact. Renewable energy

Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

6 FAQs about [Flywheel energy storage 1 kWh]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

How much energy can a flywheel store?

The small energy storage composite flywheel of American company Powerthu can operate at 53000 rpm and store 0.53 kWh of energy . The superconducting flywheel energy storage system developed by the Japan Railway Technology Research Institute has a rotational speed of 6000 rpm and a single unit energy storage capacity of 100 kW·h.

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

What is a flywheel energy storage unit?

The German company Piller has launched a flywheel energy storage unit for dynamic UPS power systems, with a power of 3 MW and energy storage of 60 MJ. It uses a high-quality metal flywheel and a high-power synchronous excitation motor.

What is a flywheel energy storage system (fess)?

Flywheel Energy Storage Systems (FESS) play an important role in the energy storage business. Its ability to cycle and deliver high power, as well as, high power gradients makes them superior for storage applications such as frequency regulation, voltage support and power firming [, , ].

What is a 7 ring flywheel energy storage system?

In 1999 , the University of Texas at Austin developed a 7-ring interference assembled composite material flywheel energy storage system and provided a stress distribution calculation method for the flywheel energy storage system.

Learn More

- Supercapacitor flywheel energy storage

- Understanding of flywheel energy storage equipment and functions of communication base stations

- What is the rotation radius of the flywheel energy storage

- How much does a flywheel energy storage room for a communication base station cost

- Wholesale of flywheel energy storage equipment for communication base stations in Cote d Ivoire

- Flywheel energy storage should be AC or DC

- New energy storage flywheel

- China s solar base station flywheel energy storage

- How much flywheel energy storage is there in Cameroon communication base stations

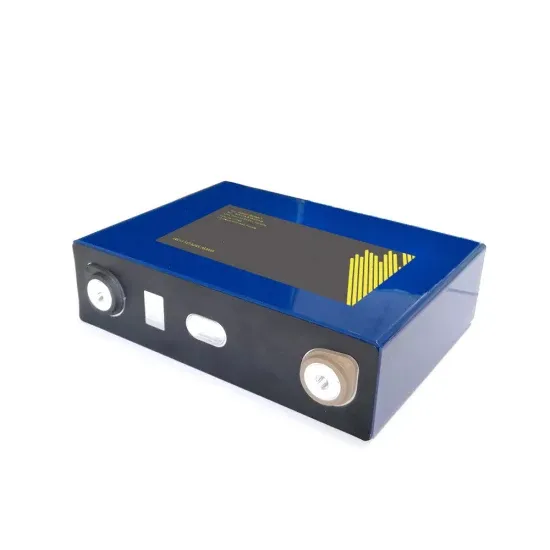

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

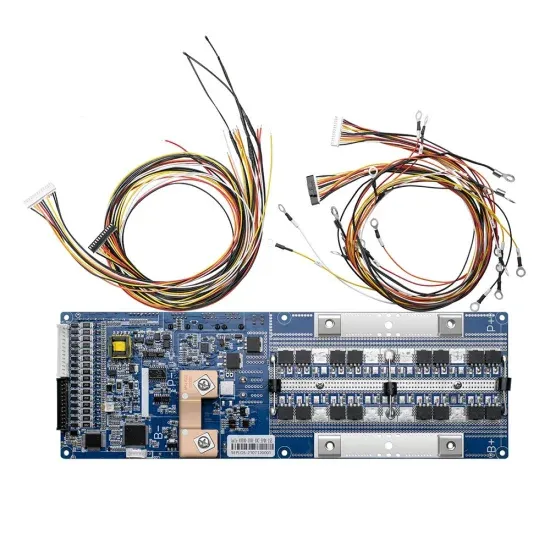

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.