Abuja Super Lithium Ion Capacitor Manufacturer

They also are found in filters and act as phase shifters in signal processing. Super capacitors are used in industry to store large amounts of energy, while other models are used in lighting.

Portugal Electrolytic Capacitor Market (2025-2031) | Analysis

Portugal Electrolytic Capacitor Market (2025-2031) | Revenue, Outlook, Value, Size, Companies, Forecast, Growth, Analysis, Trends, Segmentation, Share & Industry

List of Electrolytic Capacitor Companies in India

B2B database of Electrolytic Capacitor manufacturers, suppliers, and exporters in India containing phone numbers and emails (CEOs, Directors, Department Managers), company address,

Spain Barcelona Super Aluminum Electrolytic Capacitor

Who makes aluminum electrolytic capacitors? TTI is the premier supplier of aluminum electrolytic capacitors and is the leading authorized distributor for several world-wide manufacturers. TTI

Capacitors | Vishay

4 days ago · Capacitors Types of capacitors manufactured by Vishay include tantalum (both solid and wet), ceramic (both multilayer chip and disk), film, power, heavy-current, and alumninum.

Top 10 aluminum electrolytic capacitor manufacturers in

Apr 1, 2023 · Yunxing specializes in manufacturing aluminum electrolytic Snap-in and polymer capacitors,Products cover LED lighting,charger,adaptor,audio amplifier capacitors,Asia''x,

Top Manufacturing Companies In Porto In 2025

Porto is home to several manufacturing companies that specialize in various industries such as textiles, food processing, electronics, and automotive. These companies are known for their

The 10 Best Capacitor Suppliers In Portugal 2024

Oct 1, 2021 · We have the broadest selection of capacitor technologies in the industry, including an expanding range of electromechanical devices and electromagnetic compatibility solutions.

Who are the leading electrolytic capacitor suppliers? Top Manufacturers

Jul 4, 2024 · Electrolytic capacitors, play an important role in filtering, smoothing, and storing energy. With the electronics demand growing, such as electric vehicles, renewable energy,

Buy Wholesale Power Capacitors in Portugal | Power Capacitors

Find the best Portugal Power Capacitors and explore our extensive collection of high-quality Power Capacitors from Portugal. Buy wholesale Power Capacitors in Portugal from trusted

Acon-Official website of Shenzhen acno Electronics

Acon is a leading supplier and sales service provider of aluminum electrolytic and V-Chip capacitors in China.Acon''s capacitors are widely used in charging pile, photovoltaic inverters,

Top 7 Supercapacitors Manufacturers in the World

A capacitor which stores a huge amount of energy is known as supercapacitor. It is also known as an ultracapacitor or double-layer electrolytic capacitor. Supercapacitors have almost all

Top Capacitor Manufacturers: A Comprehensive List of

Aug 19, 2025 · Top Capacitor Manufacturers by Market Share Section 1: Manufacturer A Manufacturer A is a leading capacitor manufacturer that has been in the industry for over 50

Super electrolytic capacitor manufacturer in Porto Portugal

We are specialized in production of plastic film capacitors, Radial, SMD, Snap-in, Screw, Lug terminals Aluminum Electrolytic capacitors, and Ceramic Capacitors, Tantalum Capacitors,

5 FAQs about [Super electrolytic capacitor manufacturer in Porto Portugal]

Who makes snap-in supercapacitors?

Founded in 1944 and headquartered in Kyoto, Japan, Murata Manufacturing Co., Ltd specializes in electronic components including capacitors, sensors and power supply modules counting among the world’s largest component makers with over $5 billion in revenues. Their lineup of snap-in supercapacitors includes: Supercapacitors for Memory Backup

What are supercapacitors & ultracapacitor?

Supercapacitors or ultracapacitors offer unique advantages like ultrafast charging, reliable operation spanning millions of duty cycles alongside wide operating temperatures and collaborative integration with batteries or fuel cells for energy storage applications.

Which ultracapacitor is best for industrial backup power usage?

They provide wide reaching supercapacitor solutions including: Goldcap brand large can ultracapacitors with maximum capacitance of 2800F supporting peak power discharges. Stacked ultracapacitors modules attaining capacities of 132,000F for industrial backup power usage. The modules integrate balancing and overvoltage protection.

Why do we need Elna capacitors?

The pace of growth in information technology is accelerating. As time passes there are calls for the creation of new added-value capabilities in capacitors to respond to need for vehicle-mounted devices, for backup power supplies for communications equipment, and the like. ELNA provides solutions, focusing on parts and components.

What are Elna America supercapacitors?

ELNA America supercapacitors lineup includes commercial and automotive grades: DZ series – Slim profile screw terminal supercapacitor modules rated from 25F to 200F at 2.3V primarily aimed at peak power assist and backup across industrial segments.

Learn More

- Wellington Super Capacitor Manufacturer

- Lome Super Hybrid Capacitor Manufacturer

- Super high temperature electrolytic capacitor processing factory

- Rabat Super Electrolytic Capacitor

- Super Electrolytic Capacitor

- Tonga Communication Base Station Super Capacitor Photovoltaic Power Generation Manufacturer

- Energy storage system manufacturer in Porto Portugal

- Lithuania super capacitor manufacturer

- Portugal Porto Industrial Energy Storage Battery Manufacturer Price

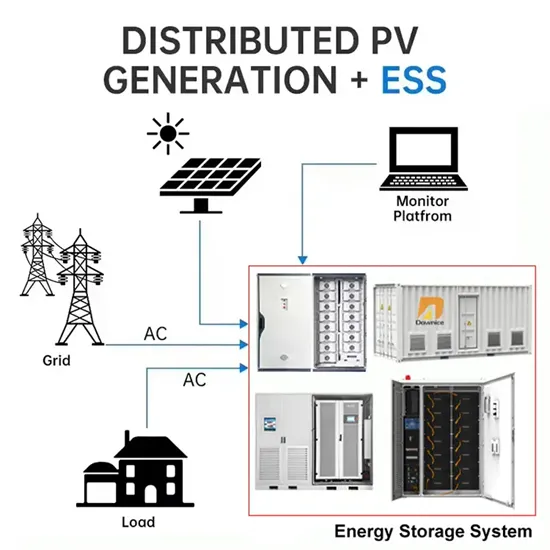

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.