Lithium Batteries in Power Tools: A Performance

Aug 16, 2025 · Before diving into the specifics of lithium-ion batteries, it''s important to understand the role that batteries play in power tools. The battery

How To Choose A Power Tool Battery?

Aug 4, 2025 · How To Choose A Power Tool Battery? As an energy storage device integrating high energy density and high voltage, lithium-ion batteries have been widely used in mobile

Power Tool Batteries: A Comprehensive Guide —

Nov 18, 2024 · Lithium-ion (Li-ion): Li-ion is the dominant chemistry for power tool batteries today. They offer the highest energy density, allowing for lighter and

Lithium Ion Batteries for Power Tools

Apr 23, 2025 · Lithium-ion batteries have transformed the power tool industry by offering high energy density, long lifespan, and fast charging. Learn how these advantages enhance the

The impact of lithium batteries on the power

Feb 28, 2025 · From power saws to drills and screwdrivers, LiPo batteries offer superior energy density, faster charging, and longer run times than traditional

Lithium Batteries in Power Tools: A Performance

Aug 16, 2025 · In this article, we will explore the benefits of lithium batteries in power tools, compare them to older battery technologies, and evaluate their

Top 10 Applications of Lithium-Ion Batteries in 2025: From

Jun 25, 2025 · Explore the top 10 uses of lithium-ion batteries in 2025, from EVs to smart grids. Learn types, benefits, and future trends with Shizen Energy.

What Are Lithium Ion Batteries? The Ultimate

Mar 15, 2025 · Electric vehicles (EVs) rely heavily on lithium-ion batteries as their primary power source, revolutionizing the way we think about transportation.

What are lithium batteries? – BatteryGuy Knowledge Base

May 3, 2024 · Lithium batteries are so called because the metal they originally used as plates is lithium based as apposed to, for example, lead in lead acid batteries. For disposable lithium

Power Tool Battery Compatibility Chart

May 25, 2021 · Home / Blog / Power Tool Battery Compatibility Chart Power Tool Battery Compatibility Chart Published on May 25, 2021. Updated on Dec 22, 2024. Compatibility chart

Application and classification of lithium batteries for electric tools.

Lithium ion batteries for electric tools are a type of high-energy, high-performance rechargeable battery. Gradually replacing traditional nickel cadmium batteries and nickel hydrogen batteries.

What Has Lithium-Ion Batteries? Devices & Uses (2025)

May 8, 2025 · What in My House Has a Lithium-Ion Battery? Many household devices contain lithium-ion batteries, including smartphones, laptops, tablets, cordless power tools, robot

Power Tool Batteries Explained: Pick up the right

Jan 23, 2019 · Latest battery innovation for cordless power devices. Like NiMH batteries, they have no memory impact and can be "bested up" with no impact

6 FAQs about [What are the lithium batteries for electric tools]

What are power tool batteries?

Power tool batteries have come a long way from bulky nickel-cadmium (NiCd) packs. Today, lithium-ion (Li-ion) technology dominates the market, offering greater power, longer runtimes, and lighter weights. This guide dives into the world of power tool batteries, exploring different chemistries, voltage platforms, amp-ho

Which chemistry is best for power tool batteries?

However, they had a higher self-discharge rate and were susceptible to damage from overcharging and overheating. Lithium-ion (Li-ion): Li-ion is the dominant chemistry for power tool batteries today. They offer the highest energy density, allowing for lighter and more powerful tools.

What tools need a high voltage battery?

Type of Tool: High-power tools like circular saws and angle grinders require higher voltage and Ah ratings. Drills and impact drivers can often use lower voltage platforms for lighter tasks. Frequency of Use: For frequent use, invest in higher Ah batteries to minimize downtime for charging.

What is a good charge level for a power tool battery?

A charge level around 40-60% is ideal for storage. Use the Correct Charger: Always use the manufacturer's recommended charger for your specific battery type. Clean Battery Contacts: Periodically clean the battery contacts with a clean, dry cloth to ensure a good connection. The Future of Power Tool Batteries:

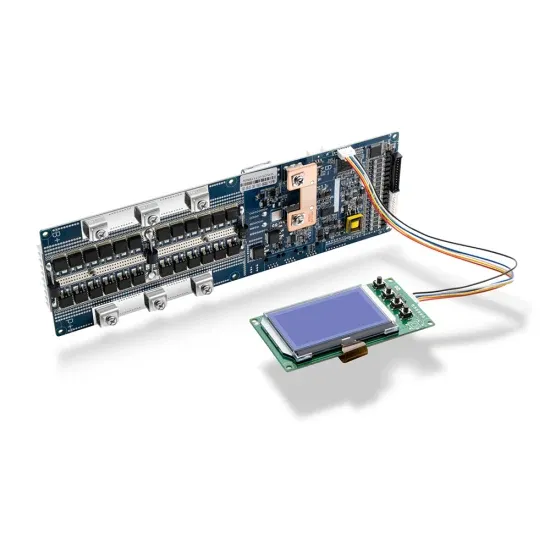

What are the components of a lithium battery pack?

There are three components to a lithium battery pack: the battery cells, the electronics, and of course, the tool. For lithium-ion to function well, electronics are essential. They control the battery and the movement of energy. The very nature of the cell chemistry requires this. Ni-Cad cells didn’t need electronics

How do electronics protect a lithium ion battery?

Paul: Electronics really play a role in protecting the battery packs thermally. Take a lithium-ion cell in excess of 75ºC (167ºF) for a sustained time, and you will do permanent damage. Electronics regulate the system and protect your investment. They also handle discharge control—a new concept that came along with this technology.

Learn More

- Selling lithium batteries for electric tools in Tajikistan

- Universal lithium battery for electric tools

- New lithium battery for electric tools

- What are the lithium batteries for photovoltaic energy storage

- What can tool lithium batteries be used for

- What was the price of energy storage cabinet batteries in the past

- Should I buy lithium batteries with BMS

- What is a dual-cell cylindrical lithium battery

- Electric impact rammer lithium battery pack

Industrial & Commercial Energy Storage Market Growth

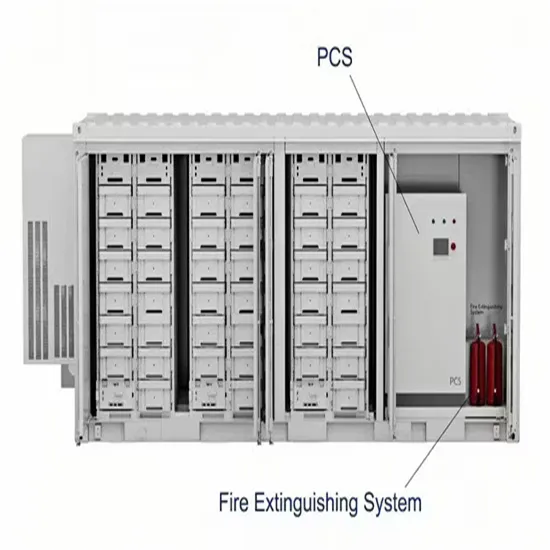

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.