12 Volt Battery Run Time Calculator

Jan 31, 2025 · Do you have a 12v device you need to power but don''t know what 12-volt battery you need? For those running a continuous 12-volt load, an adequately sized deep-cycle

Inverter Battery Size Calculator

Jul 21, 2024 · A 1000W inverter needs a bigger battery than a 600W inverter because it uses more power. A 1500W inverter requires an even bigger battery for the same backup time.

How Many Batteries Do I Need for a 600-Watt Inverter?

Feb 27, 2025 · How many batteries are needed for a 600-watt inverter? For a 600-watt inverter, you typically need 1-2 12V 100Ah lithium or lead-acid batteries to power devices for 2-4 hours.

What Size Charge Controller For 600W Solar

Nov 17, 2023 · A device that regulates direct current before it enters the battery and inverter is known as a solar charge controller. It is an important device

Solar Battery Calculator: How to Size Your Solar

Jul 31, 2025 · Learn how a solar battery calculator determines the battery capacity and the number of solar panels. Also, discover a well-sized system to

Calculate Battery Size for Inverter Calculator

Mar 14, 2025 · The Calculate Battery Size for Inverter Calculator helps you determine the optimal battery capacity needed to support your inverter system. By inputting critical parameters such

How Many Solar Panels are needed to Charge the Battery

Mar 19, 2024 · Suppose you have a battery inverter, and it is running a load of 300 watts. Now, you need to run this load from the solar panel and also charge the battery. For this, you need

How Many Batteries Do I Need for a 600-Watt Inverter?

Feb 27, 2025 · For a 600-watt inverter, you typically need 1-2 12V 100Ah lithium or lead-acid batteries to power devices for 2-4 hours. The exact number depends on battery type, depth of

How Much AH Battery is Required for Home Inverter:

Mar 15, 2025 · To find the required Ah battery for your home inverter, follow this guideline: For a 12-volt inverter, use 20% of its capacity. For a 24-volt inverter, use 10%. For example, a 500

How to Calculate Battery Size for Inverters of Any Size

So, whether you''re asking how many amps a 1500w inverter draws, trying to gauge a 2000-watt inverter''s amp draw or specifically finding out how many batteries you need for a 6000-watt

Solar Panel Size Calculator – Charge Your Battery

Apr 9, 2023 · Use our solar panel size calculator to find out the ideal solar panel size to charge your lead acid or lithium battery of any capacity and voltage.

How Many Batteries to Run a Microwave?

Having a microwave just makes food preparation so much easier, so no wonder it is a fixture in homes and RVs. But it does use a lot of power, so how many batteries will you need? That is

MPPT charge controller calculator: Find the right

Oct 16, 2024 · This MPPT calculator will determine the specifications of the MPPT charge controller that you need, provide links to MPPTs that match those

6 FAQs about [How many ah batteries are needed for a 600w inverter]

What size battery does a 1000W inverter need?

A 1000W inverter usually needs a battery with 100Ah to 150Ah capacity. The exact size depends on your load, runtime needs, and the battery type. How long will a 200Ah battery last with a 2000W inverter? A 200Ah battery can run a 2000W inverter for about 4 to 5 hours.

How much battery do I need to run a 3000-watt inverter?

You would need around 24v 150Ah Lithium or 24v 300Ah Lead-acid Battery to run a 3000-watt inverter for 1 hour at its full capacity Here's a battery size chart for any size inverter with 1 hour of load runtime Note! The input voltage of the inverter should match the battery voltage.

What is the recommended battery size for an inverter?

Interpreting Results: Once you input the required data, the calculator will generate the recommended battery size in ampere-hours (Ah). For instance, if your power consumption is 500 watts, the usage time is 4 hours, and the inverter efficiency is 90%, the calculator might suggest a battery size of approximately 222 Ah.

How long can a 100Ah battery run a 2000W inverter?

A 100Ah battery can run a 2000W inverter for about 2 to 3 hours. This is calculated by dividing the battery capacity by the load and an efficiency factor of 0.8. What is the difference between a 150Ah and a 200Ah battery? A 200Ah battery can store and deliver more energy than a 150Ah battery.

How much battery should a 500 watt inverter use?

For instance, if your power consumption is 500 watts, the usage time is 4 hours, and the inverter efficiency is 90%, the calculator might suggest a battery size of approximately 222 Ah. Practical Tips: Ensure all input values are accurate to avoid skewed results.

How to choose the best battery for a 2000W inverter?

Let’s look at some tips to help you pick the best battery. For a 2000W inverter, a 200Ah battery is a good choice. This battery can give you 2-3 hours of power for important home devices. If you want more runtime, go for a 300Ah battery, which could last up to 4-5 hours with a 2000W inverter.

Learn More

- How many batteries are needed for a 48v inverter

- How many strings of lithium batteries are needed for a 48v inverter in New York USA

- How many energy storage batteries are needed for 100mw photovoltaic

- How many solar panels and batteries are needed for a 30kw photovoltaic power station

- How many batteries are needed for 1 kilowatt photovoltaic panel

- How big an inverter is needed for home use

- How big an inverter is needed for a 1 000W solar panel

- How many cells are needed to charge tool lithium batteries

- How many batteries are needed for a 20 000 watt photovoltaic panel

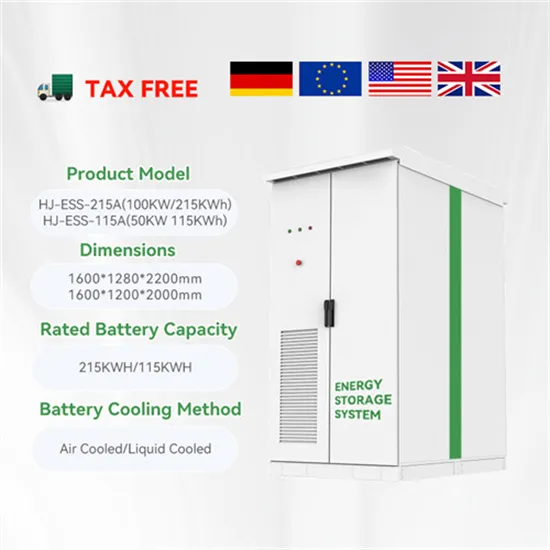

Industrial & Commercial Energy Storage Market Growth

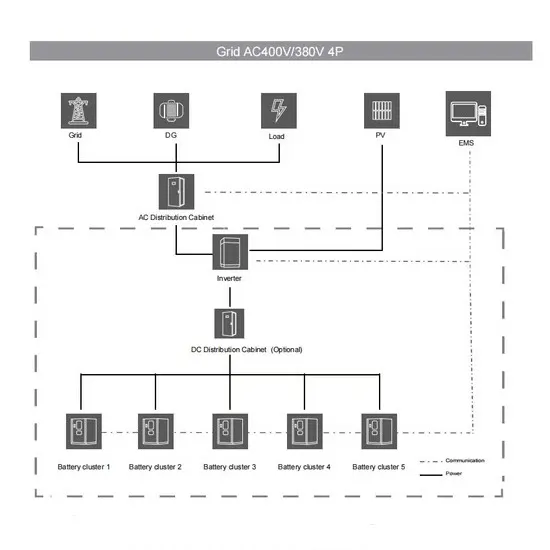

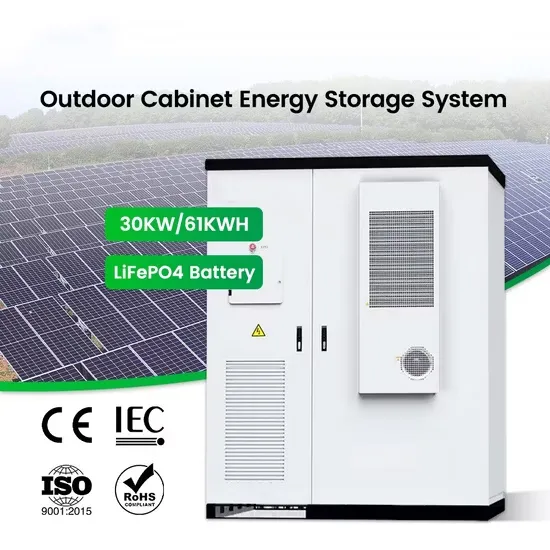

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

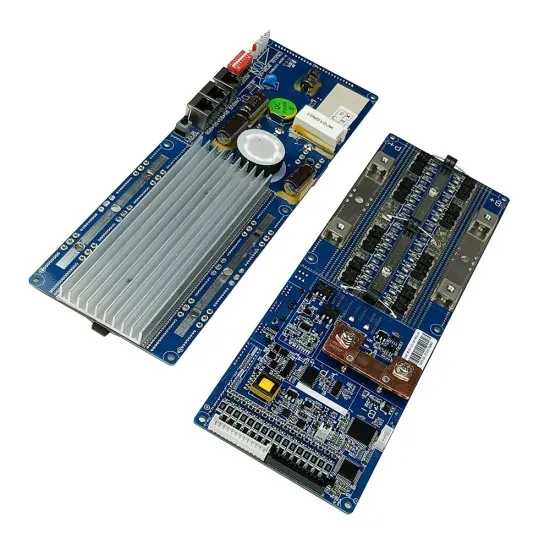

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.