Battery Cell Module Pack: Everything You Need to Know

Sep 27, 2024 · Each module contains several critical components, including module control units, battery cells, conductive connectors, plastic frames, a cooling system, end plates, and

Lithium-Ion Battery Maintenance Guidelines

Jul 9, 2025 · Lithium-Ion rechargeable batteries require routine maintenance and care in their use and handling. Read and follow the guidelines in this document to safely use Lithium-Ion

Battery Room requirements | Eng-Tips

Dec 17, 2009 · If you are required to have the batteries in a separate room (by your NEC), you should definitely use as much precautions as you can (light switches outside the room, no

What is a Battery Pack? Definition, Types, Applications, and

Dec 10, 2024 · A battery pack is a set of batteries or battery cells arranged in series or parallel to supply power. It stores energy for devices like electric vehicles.

Battery Packs and Assemblies Selection Guide: Types,

Battery packs are the heart of electric vehicles, but what goes into making a safe and reliable one? This article explores the various requirements that battery packs need to meet. Charging:

What is a Battery Pack? Definition, Types, Applications, and

Dec 10, 2024 · Battery packs come in various configurations, including lithium-ion, nickel-metal hydride, and lead-acid. They are designed with a battery management system (BMS) for

What Is a Power Pack and How Does It Work?

May 24, 2025 · Photo by Hendrik Morkel / Unsplash Power packs are revolutionizing how we access and store energy for portable and off-grid applications. As an essential tool for modern

What equipment is required for battery pack

Its business covers battery materials, battery pack manufacturing, research and development of intelligent battery testing equipment, battery cascading utilization testing, second-hand battery

How to choose the right battery pack to meet the needs of

Different devices have varying power requirements; for instance, smartphones typically need between 5-20 watts, while laptops might require 30 watts or more. Therefore, selecting a

FX_HowToPack_Batteries_CA_EN_401131600

Sep 24, 2023 · For proper shipping names ending in "Packed with Equipment," Packing Instructions 966 and 969 indicate that the number of cells or batteries in each package must

The Fundamentals of Battery/Module Pack Test

Oct 17, 2023 · The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy

What Precautions Should You Take When Packing Lithium Ion Batteries

Jul 15, 2025 · Final Thoughts: Traveling Safely with Lithium-Ion Batteries Frequently Asked Questions About Packing Lithium Ion Batteries for Flights Can I pack lithium batteries in

What equipment is required for lithium battery pack and lithium battery

Nov 12, 2019 · What equipment is required for lithium battery pack and lithium battery pack processing? The manufacture of lithium batteries can be divided into four stages: pole piece

What equipment do you need to know about energy storage packs?

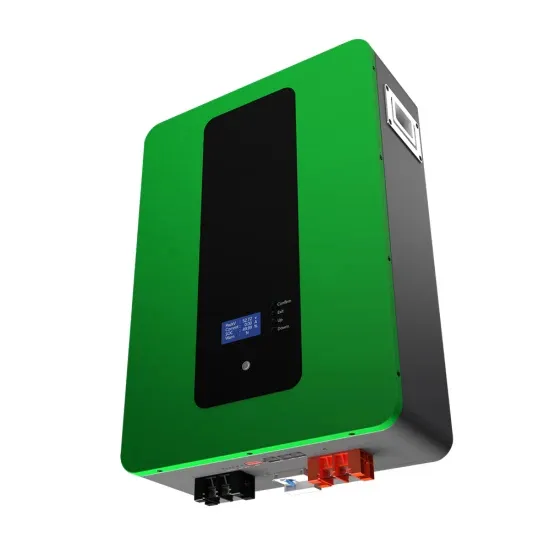

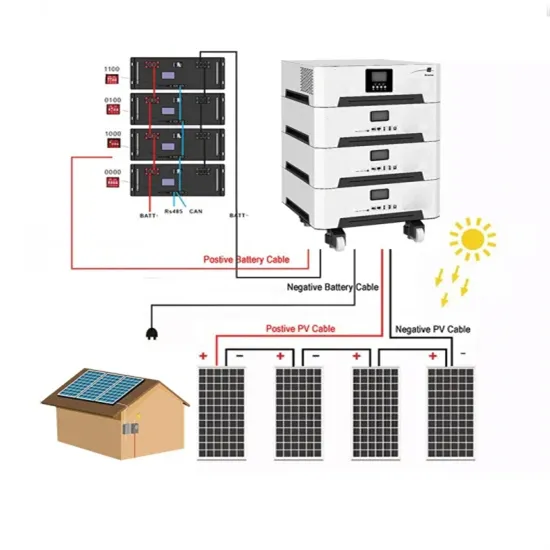

Feb 20, 2024 · A wide variety of batteries are integral to energy storage packs, with lithium-ion, lead-acid, and flow batteries standing out as the most common. Lithium-ion batteries are

Battery Packs Explained: How They Work, Usage, and a

Feb 28, 2025 · In summary, battery packs come in various types and configurations to suit a wide range of applications, from consumer electronics to automotive uses and custom installations.

What is "S" and "P" in a battery pack?

For example, electric vehicles generally require high-voltage and large-capacity battery packs, while smartphones require large-capacity and small-volume battery packs. In summary, S and

Emergency Light UPS backed VS Battery Pack

Feb 18, 2019 · Greetings, I was wondering which one you favor more. This is to power the emergency lights. This is for a commercial project that has about 150 emergency lighting

What Are the Components of a Battery Pack?

Because battery packs are a versatile power source, they can be arranged to fit unusual spaces and still provide a constant supply of energy. What You''ll Find In a Battery Pack The

6 FAQs about [What equipment does a battery pack require ]

What are battery packs?

Battery packs are constructed from two or more individual cells or batteries. They come in two basic types: primary and secondary or rechargeable. Primary batteries are disposable, non-rechargeable devices that must be replaced once their energy supply is depleted.

What are the two basic types of battery packs?

There are two basic types of battery packs: primary and secondary or rechargeable. Primary batteries are disposable, non-rechargeable devices. They must be replaced once their energy supply is depleted. Battery packs are constructed from two or more individual cells or batteries.

What makes a good battery pack?

Matching these specifications ensures proper functioning. Battery type: There are mainly two types of battery packs: lithium-ion and lithium-polymer. Lithium-ion batteries offer higher energy density and are more common in power banks. Lithium-polymer batteries are lighter and more flexible in shape, but they usually have a lower energy density.

How to choose a battery pack for beginners?

Multiple ports allow charging of multiple devices simultaneously. Safety features, such as short circuit protection, ensure safe operation and longevity of the device. By considering these points, beginners can choose a battery pack that meets their requirements effectively and safely.

Why do medical devices need a battery pack?

Battery packs in medical devices ensure that critical equipment remains operational when not plugged in. Devices like portable ventilators and blood glucose monitors often rely on battery power.

What is a lithium-ion battery pack?

A lithium-ion battery pack is a collection of multiple lithium-ion cells connected together to store and provide electrical energy. These battery packs power various electronic devices, from smartphones to electric vehicles, due to their high energy density and rechargeable nature.

Learn More

- What equipment does the cabinet battery pack factory need

- What equipment is needed to make lithium battery pack

- What is the use of 48v lithium battery pack

- What does lithium battery pack consistency mean

- What is the average lifespan of a lithium battery pack

- What shock absorption is used for lithium battery pack

- What is the battery capacity of base station communication equipment

- What does lithium battery pack gram mean

- Lithium battery pack bulk charging equipment

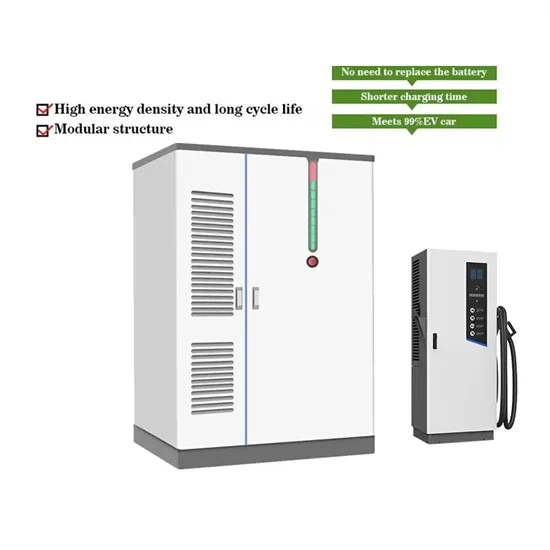

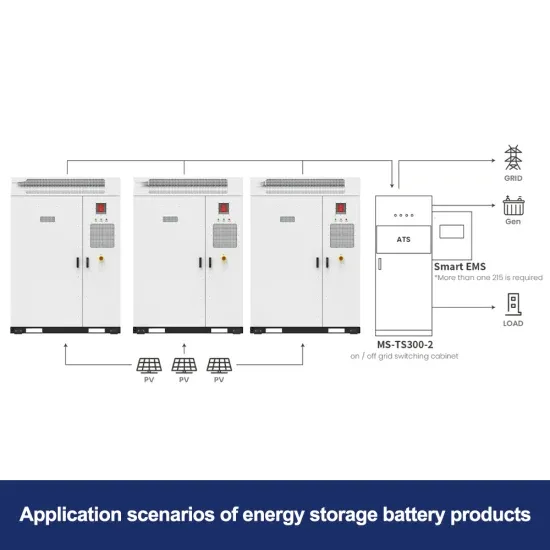

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.