Energy Storage Container Security Measures | Enerlution

Aug 6, 2024 · To sum up, safeguarding energy storage containers involves a multifaceted approach that integrates physical security measures, robust cybersecurity protocols, structural

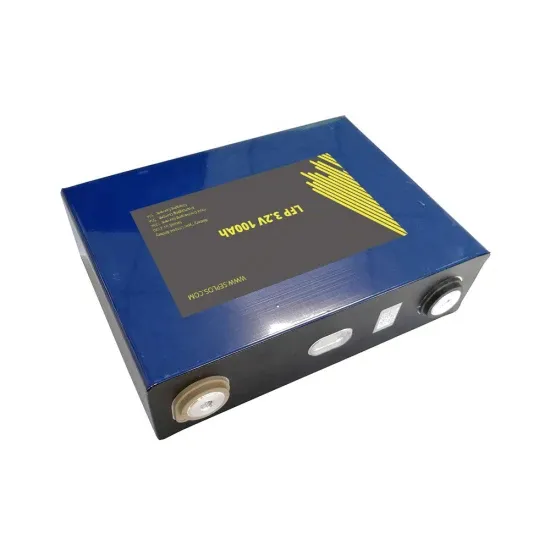

The Key Role of Battery Management Systems (BMS) in Energy Storage

Jun 5, 2024 · Discover how Battery Management Systems (BMS) are crucial to the efficiency, safety, and reliability of energy storage systems, ensuring optimal performance and longevity.

Comprehensive Guide to Energy Storage Management

May 3, 2024 · The top layer is the centralized monitoring system, while the bottom layer devices like storage inverters, Battery Management Systems (BMS), environmental monitoring

Energy Storage Monitoring System Design: The Backbone of

Oct 25, 2024 · Now multiply that risk by 10,000, and you''ll understand why energy storage monitoring systems are critical for industrial-scale battery farms. These systems are like the

Sensing the Pulse of Battery Energy Storage Systems: An In

Apr 24, 2023 · Discover the integral role sensors play in monitoring and managing Battery Energy Storage Systems (BESS) containers. Learn how door status sensors, temperature sensors,

Operational risk analysis of a containerized lithium-ion battery energy

Aug 1, 2023 · Consequently, various countries and organizations are closely monitoring energy storage safety, and continually updating and releasing relevant standards and regulations.

Operational risk analysis of a containerized lithium-ion battery energy

Aug 1, 2023 · Loss scenario S14-N-5: When the off-gas concentration of the container is too high, the sensor responds normally, but the safety monitoring management system does not receive

An Environment Control Management System for Container-Type Energy

Aug 18, 2025 · The ECS adopted sensors to monitor the BESS site and the batteries, preparing for potential disasters. It continuously collected environmental monitoring data and was

Container energy storage system environment

omponents of the Energy Storage EMS system. An Energy Storage EMS, or Energy Management System, is a critical pillar of any storage system. It provides data management, monitoring,

An Environment Control Management System for Container-Type Energy

Aug 13, 2023 · The most widely used energy storage system in current industrial applications and commercialization is Battery Energy Storage System (BESS). Due to its fast res

Container Battery Energy Storage System Manufacturer | AEME

AEME''s Container BESS features integrated battery safety design and advanced thermal management, and can be used in different scenarios and environments. It supports high

Key Design Considerations for Energy Storage Containers

Apr 11, 2025 · The design of energy storage containers involves an integrated approach across material selection, structural integrity, and comprehensive safety measures. Choosing the right

Energy Storage Container Handling Techniques | Enerlution

Aug 17, 2024 · By understanding the environmental impacts and the importance of proper disposal, all parties can contribute to more sustainable operations. In conclusion, the handling

How are energy storage containers configured? | NenPower

Aug 2, 2024 · 1. Energy storage containers are configured using a variety of design principles and technical elements to optimize efficiency, safety, and usability. These configurations

What are the container energy storage monitoring systems

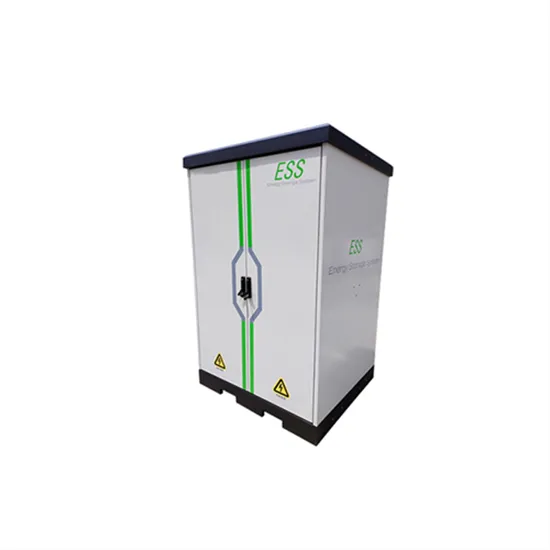

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from renewable

An Environment Control Management System for Container-Type Energy

Aug 13, 2023 · The most widely used energy storage system in current industrial applications and commercialization is Battery Energy Storage System (BESS). Due to its fast response

Containerized Energy Storage

Dec 7, 2022 · Containerized Energy Storage Vericom energy storage container adopts All-in-one design, integrated container, refrigeration system, battery module, PCS, fire protection,

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

Battery Management System (BMS) in Battery Energy Storage

Sep 15, 2024 · Battery Management Systems (BMS) are integral to Battery Energy Storage Systems (BESS), ensuring safe, reliable, and efficient energy storage. As the "brain" of the

Container energy storage system environment

Battery Management Systems (BMS) are integral to Battery Energy Storage Systems (BESS), ensuring safe, reliable, and efficient energy storage. As the "brain" of the battery pack, BMS is

The Monitoring and Management of an Operating Environment

The implementation of an energy storage system (ESS) as a container-type package is common due to its ease of installation, management, and safety. The control of the operating

The Monitoring and Management of an Operating

May 12, 2023 · The implementation of an energy storage system (ESS) as a container-type package is common due to its ease of installation, management, and safety. The control of the

Sensing the Pulse of Battery Energy Storage Systems: An In

Apr 24, 2023 · Battery Energy Storage Systems (BESS) are complex systems that require precise monitoring to ensure they operate safely and efficiently. Sensors play a crucial role in this

Energy Storage Containers: Elite Guardians Of Power Supply

Jul 31, 2025 · Energy Storage Containers: Elite Guardians Of Power Supply in Extreme Environments Jul 31, 2025 Leave a message In extreme environments such as deserts and

6 FAQs about [Energy Storage Container Environmental Monitoring]

What is an energy storage system (ESS)?

The implementation of an energy storage system (ESS) as a container-type package is common due to its ease of installation, management, and safety. The control of the operating environment of an ESS mainly considers the temperature rise due to the heat generated through the battery operation.

What is an energy storage system?

Introduction An energy storage system (ESS) is a system that has the flexibility to store power and use it when required. An ESS can be one of the solutions to mitigate the intermittency effect of variable renewable energy (VRE), such as photovoltaic and wind power [1, 2, 3].

What does an energy storage system (EMS) do?

The EMS is mainly responsible for aggregating and uploading battery data of the energy storage system and issuing energy storage strategies to the power conversion system. These actions help it to strategically complete the AC-DC conversion, control the charging and discharging of the battery, and meet the power demand.

What is the operating environment of an ESS container?

The operating environment of an ESS must be managed within the operating range provided by the manufacturer. It is recommended that the ESS container used in this study be operated at 35~75% humidity and 18~28 °C. Figure 2 shows an example of the relative humidity, temperature of the container, and battery cell temperature during summer.

How to control the indoor temperature of ESS containers?

The indoor temperature of the ESS container can be controlled to maintain the battery temperature below the target temperature. Generally, economical and simple forced air convection systems (FACS) are used to manage the indoor temperature of ESS containers .

What happens if the energy storage system fails?

UCA5-N: When the energy storage system fails, the safety monitoring management system does not provide linkage protection logic. [H5] UCA5-P: When the energy storage system fails, the safety monitoring management system provides the wrong linkage protection logic.

Learn More

- Monitoring equipment inside the energy storage container

- Israel container energy storage fire exhaust fan wholesale

- Peruvian iron-lithium battery energy storage container supplier

- Mali integrated energy storage container 5g base station

- What kind of battery is the energy storage container battery

- ASEAN container mobile house energy storage box

- Suriname Energy Storage Container Overseas

- Uruguay Energy Storage Container Procurement Announcement

- Container Energy Storage Power System Base Station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.