What Will An Inverter Run & For How Long?

Mar 3, 2023 · How long will a 12v battery last with an inverter? The next question which comes to mind that how long my inverter will last on load with a 12, 24,

Understanding Inverter Input And Output: What

3 days ago · Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC

Amazon : 12 Volt Power Inverter: Electronics

5000 watt Power Inverter DC 12V to AC 110V/120V Converter,10000w Peak es with LCD Display,Wireless Controller, 4AC outlets,1USB.RV Inverter,Suitable for Camping,and Off-Grid

How bad, if at all, is 14.4V overvoltage for 12V inverter?

May 9, 2023 · My question is, can the 12V inverter still function as reliably under these higher 14.4V overvoltages? And related to that what should the overvoltage be set to for max inverter

12V vs 24V vs 48V Inverter: How to Choose the Right System

Jun 16, 2025 · Confused about choosing between 12V, 24V, or 48V inverter systems? Discover which voltage is best for RV, solar, and off-grid setups. Learn the pros, cons, efficiency, cable

Calculate Battery Size For Any Size Inverter

Mar 3, 2023 · Battery size chart for inverter Note! The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter,

Understanding inverter voltage

Jan 10, 2024 · For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and

Renogy Inverter P2 3000W Pure Sine Wave Inverter 12V DC

Jun 4, 2021 · About this item 【POWERFUL DC-AC】This 3000 watt inverter 12V to 110V provides 3000W continuous DC to AC power, 6000W peak surge during load start-up, 12V to 120V AC pure sine wave with conversion efficiency >90%, reduces conversion loss. 【SAFE FOR

6 FAQs about [12v inverter 510v voltage]

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

What is a safe voltage for a 12V inverter?

For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and protect the inverter from potential damage. What happens if voltage is too high for inverter?

What are inverter voltage ratings?

Inverter voltage ratings are critical to ensure compatibility with your solar system and battery setup. Pay attention to these numbers. When selecting an inverter, understanding voltage ratings ensures proper system compatibility, efficiency, and longevity. Key ratings to focus on include rated voltage, maximum input voltage, and others.

Can a 12V 72V inverter be converted to each other?

A1: No, 12V~72V cannot be converted to each other. You can only choose one of the input voltages, and the inverter input voltage must be consistent with the system input voltage. For example: a 72V inverter can only be used for a 72V battery. Q2: How to select the output voltage:

What is a power inverter?

Inverters Guide from 12 Volt Planet. Power inverters, or simply inverters, are transformers that will convert a DC current into an AC current, allowing you to run higher voltage equipment from a battery or other DC power source

What is the maximum input voltage for a residential inverter?

Typically, residential inverters have a maximum input voltage between 500V and 1000V. Choosing one with a higher rating ensures greater flexibility and better performance in different weather conditions.

Learn More

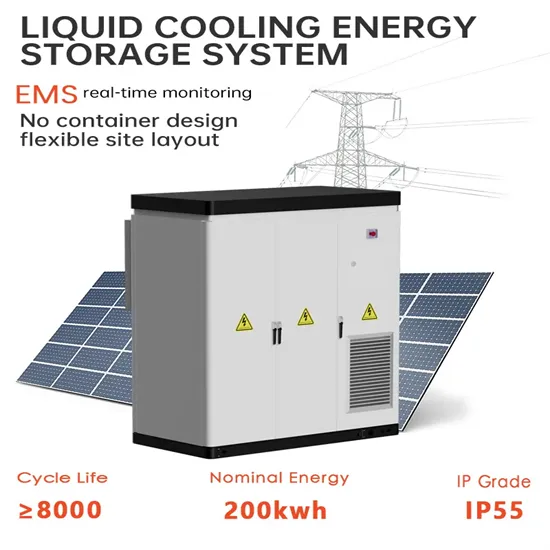

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.