Experimental and numerical investigation on thermal

Dec 5, 2015 · The cabinet''s ability to protect the batteries from an ambient temperature as high as 50 °C is studied. An experimental facility is developed to measure the battery surface

Comprehensive fault diagnosis of lithium-ion batteries: An

Feb 1, 2025 · The experimental results demonstrate that the algorithm can quickly converge to the optimal or near-optimal solution across different fault scenarios, exhibiting strong convergence

Analysis of Influencing Factors of Battery Cabinet Heat

For the lithium iron phosphate lithium ion battery system cabinet: A numerical model of the battery system is constructed and the temperature field and airflow organization in the battery cabinet

Study on performance effects for battery energy storage

Feb 1, 2025 · The purpose of this study is to develop appropriate battery thermal management system to keep the battery at the optimal temperature, which is very important for electrical

Machine Learning Approaches in Battery Management

Jul 19, 2021 · Note that the likelihood algorithm uses the battery terminal voltage and current information that are measured by logged by the power management integrated circuit (PMIC).

Research on the Location Selection Problem of Electric Bicycle Battery

Oct 3, 2024 · However, current battery exchange cabinets face the problems of insufficient construction and unreasonable site selection. Therefore, this paper proposes a location

Research on the Location Selection Problem of

Sep 26, 2024 · However, current battery exchange cabinets face the problems of insufficient construction and unreasonable site selection. Therefore, this paper

Experimental and numerical investigation on thermal

Dec 5, 2015 · In this paper, the flow field and temperature distribution inside an outdoor cabinet are studied experimentally and numerically. The battery cabinets house 24 batteries in two

Battery Performance | Energy Futures Lab | Imperial College

Oct 4, 2024 · Lithium-ion batteries stand as the dominant power source technology for EVs. Understanding the behaviour of lithium-ion battery cells is crucial for the optimisation of their

Lithium-ion battery RUL prediction based on optimized VMD

Jul 23, 2025 · Experimental validation on the NASA Battery dataset and NASA Randomized Battery Usage Dataset demonstrates that the proposed WOA-VMD-SSA-PatchTST model

Intelligent algorithms and control strategies for battery management

Apr 10, 2021 · To address these concerns, an effective battery management system plays a crucial role in enhancing battery performance including precise monitoring, charging

Research on the Location Selection Problem of Electric Bicycle Battery

Sep 26, 2024 · The increase of objective value along with the number of cabinets is self-evident. The comparison of two algorithms is insufficient. What is the traditional immune algorithm like?

Experimental Analysis of Battery Management System

Aug 15, 2019 · Abstract The large use of lithium batteries as energy storage pushes researches to find new systems to make them work in safe conditions, to estimate their state of charge and

Multi-scale modelling of battery cooling systems for grid

Feb 22, 2025 · The introduction of battery energy storage systems is crucial for addressing the challenges associated with reduced grid stability that arise from the large-scale integration of

PERFORMANCE INVESTIGATION OF THERMAL

Nov 11, 2023 · nsistent dissolving behavior, including dissolving fraction and temper-ature uniformity. An experimental and numerical examination of the thermal management of an

Mathematical Characterization of Battery Models

Jan 28, 2021 · An equivalent circuit battery model in [2] [3] is used to represent battery terminal voltage dynamics as a function of battery current. The model is based on Thevenin''s theorem

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · We studied the fluid dynamics and heat transfer phenomena of a single cell, 16-cell modules, battery packs, and cabinet through computer simulations and experimental

Experimental and numerical investigation on thermal

The battery cabinets house 24 batteries in two configurations namely, two-layer configuration and six-layer configuration respectively. The cabinet walls are maintained at a constant

State-of-the-Art Review: Models and Algorithms for

Dec 3, 2024 · The stability and reliability of power systems are essential for effective operation and design. Models and algorithms are instrumental in bolstering stability, especially using

Analysis of Influencing Factors of Battery Cabinet Heat

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

[2404.12774] Recent Advancements in Battery State of

Apr 19, 2024 · Accurate state of power (SOP) estimation is of great importance for lithium-ion batteries in safety-critical and power-intensive applications for electric vehicles. This review

Capacity optimization of battery and thermal energy storage

Jun 1, 2025 · This study explores the configuration challenges of Battery Energy Storage Systems (BESS) and Thermal Energy Storage Systems (TESS) within DC microgrids, particularly

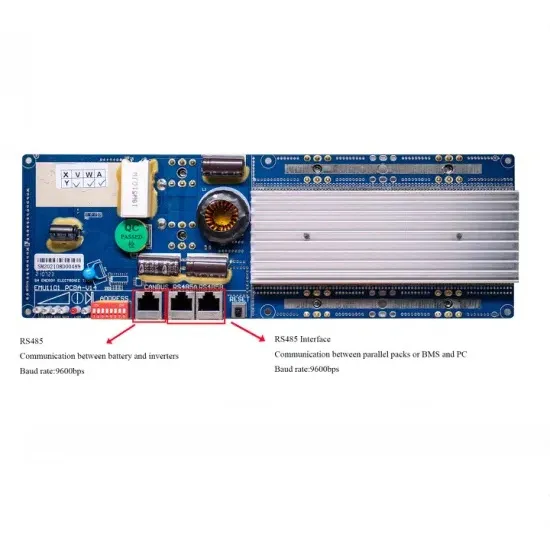

Battery cabinet current algorithm principle

Paper studies the charging strategies for the lithium-ion battery using a power loss model with optimization algorithms to find an optimal current profile that reduces battery energy losses

A systematic review of thermal management techniques for

Jan 1, 2024 · In the current era of sustainable energy and countries'' efforts to reduce carbon emissions and transition to green transportation, lithium batteries h

6 FAQs about [Battery cabinet current algorithm experimental report]

What is an equivalent circuit battery model?

An equivalent circuit battery model in is used to represent battery terminal voltage dynamics as a function of battery current. The model is based on Thevenin’s theorem to model the current and voltage profile of the battery as a black box input-output device.

How can a more accurate battery model be developed?

(20) A more accurate battery model may be developed by adding the Redlich-Kister expansion to (20) as shown in equation (16). A summary of the constants and the variables to be identified by Nelder-Mead is presented in Table 4.

What is model-based battery SoC estimation?

Model-based battery SOC estimation has been developed here using an equivalent circuit representation . Various methods of analyses for performance and conditions under which the model state is observable have been proposed and demonstrated using simulated and experimental battery data .

What is a battery state observer?

State observers are used to update battery state estimates based on observations of current and voltage at the battery output terminals. An equivalent circuit battery model in is used to represent battery terminal voltage dynamics as a function of battery current.

Can extended Kalman filter be used for battery state estimation?

The purpose of this document is to demonstrate the use of the Extended Kalman Filter as a tool for battery state estimation and the estimation of battery state of charge. The mathematical details based on the equivalent circuit model are presented followed by an electrochemical engineering model.

Can octocopter battery models be observable in real-time?

A simplified electrochemistry model was introduced, and observability explored. State observability was explored with both laboratory test data and data gathered during the flight of an octocopter. For the battery models examined, the extended Kalman filter offers a way to produce approximate state observations in real-time.

Learn More

- Discharge current of nickel-cadmium battery in energy storage cabinet

- Energy storage battery cabinet current detection price

- Battery cabinet base station power current abnormality

- Site Energy Battery Cabinet Research Report

- Battery cabinet power test report

- What is the current of the battery cell in the battery cabinet

- How to calculate power and current in battery cabinet

- New Energy Battery Cabinet Base Station Energy Equipment

- Communication power supply supporting battery cabinet

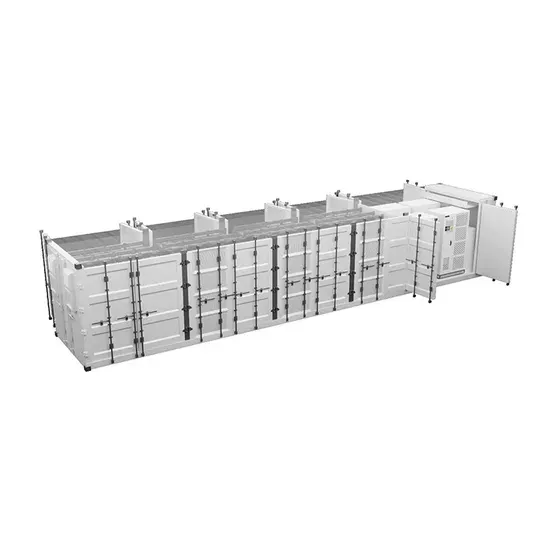

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.