Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Optimal design of micro flywheel energy storage system

Nov 17, 2008 · We have designed a micro flywheel energy storage system in which the flywheel stores electrical energy in terms of kinetic energy and converts this kinetic energy into

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

ABB to minimise diesel in Africa micro-grids

Sep 9, 2015 · For the first project, ABB, known in the solar industry for its invertor technology, won an order from Kenya-based robotics and renewable energy

Energy recovery for hybrid hydraulic excavators: flywheel

Mar 3, 2021 · Hybridization is an effective method to reduce fuel consumption and emissions of toxic pollutants generated by hydraulic excavators (HEs). This paper first reviews various

Energy Storage | Falcon Flywheels | England

Grid-Scale Kinetic Energy Storage Falcon Flywheels is an early-stage startup developing flywheel energy storage for electricity grids around the world. The rapid fluctuation of wind and solar

Kenya''s Storage Market Is Budding

Sep 14, 2015 · Kenya will soon be getting its first flywheel storage project. The system, commissioned by Socabelec East Africa, is intended to support a microgrid serving a

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Fast Response Flywheel Energy Storage Technology for

Aug 31, 2018 · The continued expansion of renewable energy sources like wind power and photovoltaics is gradually reducing short and long-term grid stability, especially as more and

Control solution for flywheel energy storage systems

Feb 28, 2024 · To make operation of mobile machines more efficient, flywheel-based energy storage can be used. It absorbs energy during low-load periods and releases it during peak

Techno-economic analysis and dynamic power simulation of

Apr 6, 2023 · Sub-Saharan Africa (SSA) has the lowest energy access rates globally. The need for transformative energy sources ranging from solar off-grid and mini-grid solutions to hybrid

Energy recovery for hybrid hydraulic excavators: flywheel

May 1, 2021 · In light of this, the differences between HEs and automobiles are discussed to highlight the potential of flywheel-based ERSs in HEs. Then, the paper compares

Assessment of photovoltaic powered flywheel energy storage

Nov 1, 2023 · Proposed system improved the reliability of the power supplied to the load. Energy storage and power conditioning are the two major issues related to renewable energy-based

Flywheel energy storage application installed underground

Flywheel energy storage is reaching maturity, with 500 flywheel power buffer systems being deployed for London buses (resulting in fuel savings of over 20%), 400 flywheels in operation

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · In this paper, state-of-the-art and future opportunities for flywheel energy storage systems are reviewed. The FESS technology is an interdisciplinary, complex subject that

Flywheel Energy Storage in East Africa: Powering the Future

Oct 15, 2019 · Enter flywheel energy storage, the Usain Bolt of energy storage solutions. With its ability to respond in milliseconds, this technology could be the game-changer for balancing

Excavator Pilot Energy Storage Devices: The Secret Sauce to

Oct 24, 2024 · Imagine a construction site where excavators hum like caffeinated worker bees – but instead of coffee, they''re powered by their own wasted energy. That''s the magic of

Techno-economic analysis and dynamic power simulation of

Apr 1, 2023 · This research proposes a hybrid photovoltaic-wind turbine power system coupled to a hybridized storage system composed of a Lithium-Ion battery and a flywheel storage system

6 FAQs about [Kenya Micro Excavator Flywheel Energy Storage]

Are flywheel energy storage systems feasible?

Vaal University of Technology, Vanderbijlpark, Sou th Africa. Abstract - This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage.

How does the flywheel energy storage system work?

However, in the proposed HRES, the flywheel energy storage system (FESS) alleviates possible blackouts due to frequency-based power imbalance. Based on the operation profile shown in Figure 29, FESS is charged with positive torque generated upon excess power from the combined solar/wind output, wind power system, or PV power system.

What is a hydraulic excavator boom subsystem with a flywheel-based energy recovery system?

Schematic of a hydraulic excavator boom subsystem with the flywheel-based energy recovery system. In Fig. 10, a flywheel is employed as the energy storage device in the assistant power source. Considering the existing boom cylinder, a hydraulic machine is used as an energy converter.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheels competitive with other hydraulic excavators?

A comprehensive comparison shows that flywheels are competitive with other rivals in the field of hydraulic excavators. The current challenges to flywheel technology, conclusions, and future work are presented. Hybridization is an effective method to reduce fuel consumption and emissions of toxic pollutants generated by hydraulic excavators (HEs).

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

Learn More

- How to build a flywheel energy storage project for a communication base station

- Communication base station flywheel energy storage user hybrid power supply

- EK flywheel energy storage equipment

- Ashgabat Motor Flywheel Energy Storage

- Does the flywheel have a large energy storage capacity

- Safe distance of flywheel energy storage at St John s communication base station

- Price of the fifth generation flywheel energy storage

- Does Kyrgyzstan have flywheel energy storage for communication base stations

- Flywheel energy storage system connected to the grid

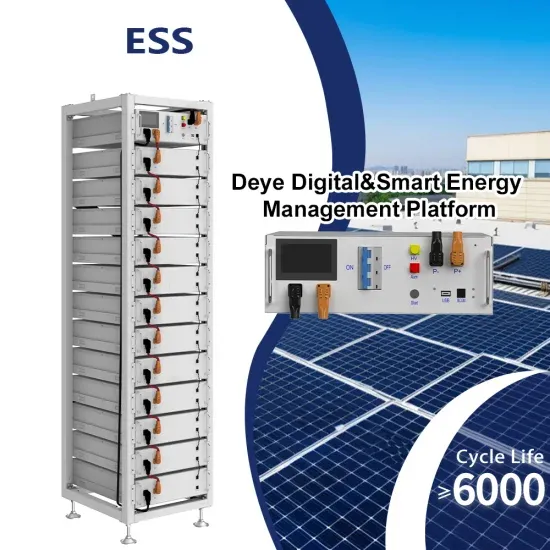

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.