Fabrication of Free Energy Generation Using Flywheel

Dec 23, 2024 · Abstract- Flywheels have been under consideration to be used for energy storage purposes, with rapid growth in the economy, the demand for electricity is also increasing. With

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

The development of a techno-economic model for the

Oct 1, 2021 · Two rotor configurations were considered: composite rotor flywheel and steel rotor flywheel. The total investment costs of the composite rotor and steel rotor flywheel storage

Top 5 Advanced Flywheel Energy Storage Startups in 2025

Aug 13, 2025 · This article explores five early and growth-stage advanced flywheel energy storage startups leading the next era of sustainable energy solutions. These startups have the

Opportunities in Flywheel Energy Storage Market 2025-2033

May 14, 2025 · The flywheel energy storage market, currently valued at $159.6 million in 2025, is projected to experience steady growth, driven by increasing demand for reliable and efficient

Flywheels Turn Superconducting to Reinvigorate

Apr 7, 2021 · The flywheel has fallen off many people''s radar since the industry''s leader, Beacon Power, filed for bankruptcy in 2011. Though the company was

RotorVault Energy Storage Cost Analysis and Flywheel Price

5 days ago · Compared to other technologies like supercapacitors and legacy flywheels, RotorVault has much lower CAPEX and better storage capacity. Explore RotorVault''s cost

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Flywheel Energy Storage Costs: Breaking Down the

Current flywheel installations average $1,100-$1,500 per kW compared to $700-$900/kW for lithium batteries [1] [10]. However, when considering total lifecycle value, the picture changes

Flywheel energy and power storage systems

Feb 1, 2007 · Today flywheels are used as supplementary UPS storage at several industries world over. Future applications span a wide range including electric vehicles, intermediate

Concrete flywheel storage system for residential

Jun 21, 2021 · A French start-up has developed a concrete flywheel to store solar energy in an innovative way. Currently being tested in France, the storage

Flywheel Energy Storage Study

May 4, 2020 · The core of this particular FES System technology involves the development of a lower-cost steel flywheel, which will reduce the first cost of the energy storage device, while

Understanding the Cost of Flywheel Energy Storage Systems:

Jun 16, 2019 · Why Flywheel Energy Storage Is Making Headlines (and Headaches) Let''s face it – when someone says "energy storage," your brain probably jumps to lithium-ion batteries faster

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

6 FAQs about [Price of the fifth generation flywheel energy storage]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

How much does rotor flywheel storage cost?

A bottom-up cost model was developed to assess the levelized cost of flywheel storage. Composite and steel rotor flywheels were assessed for frequency regulation. The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively.

How much does a flywheel power converter cost?

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

Are flywheel energy storage systems a good alternative to electro-chemical batteries?

Electro-chemical ESSs can be used in short-duration services , , but they suffer from a short lifetime and the need to dispose of toxic materials , . Flywheel energy storage systems (FESSs) are a promising alternative to electro-chemical batteries for short-duration support to the grid .

Learn More

- Price of energy storage power generation

- Flywheel energy storage application in wind power generation

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- Flywheel energy storage system price

- Shanghai greenhouse photovoltaic power generation energy storage pump

- Energy storage photovoltaic power generation makes money

- Kathmandu integrated energy storage cabinet wholesale price

- Middle East photovoltaic energy storage 15kw inverter price

- Energy Storage Distributed Generation

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

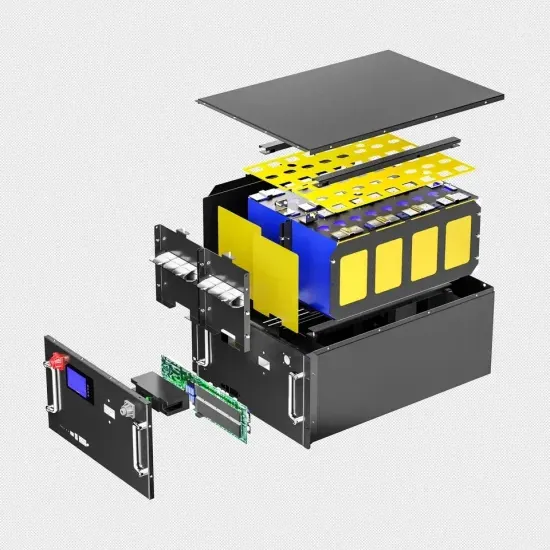

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.