Eaton Samsung Gen 3 Battery Cabinet Installation and

Mar 25, 2025 · Contact your local Authorities Having Jurisdiction (AHJ), to discuss the planned lithium battery installation, including cabinet placement and spacing, as well as total quantities

Installation and Operation Manual

Nov 27, 2023 · Ranging from small battery enclosures to cabinets including gear trays, you can pre-build and test in the workshop, simplifying site installation. PowerPlus Energy cabinets are

How to correctly install lithium battery energy

Mar 25, 2024 · In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

Eaton 93E External Battery Cabinet installation manual

Sep 23, 2024 · Route the other end of the battery cables (positive, negative, and ground) to the UPS cabinet external battery input and ground terminals. Refer to the applicable Eaton 93E

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · 6.2.2 EQUIPMENT MOUNTING Do not attempt to unpack or move the battery cabinet without assistance. Use appropriate handling equipment rated to bear the weight and

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Battery Cabinet

Feb 28, 2025 · This chapter describes the Battery Cabinet installation operations that are required before proceeding with the cable termination and equipment turn-up. The following information

Battery integrated cabinet assembly tutorial diagram

The outdoor integrated cabinet is uesd in small capacity base stations, equipment and battery integrated cabinets can be used. The equipment put at the upper layer and the battery put

Lithium battery cabinet installation instructions

How to mount a battery pack to a wall? It is recommended to mount the battery pack to a wall. Make sure to leave a space of at last2.18 inches in between the battery pack and the wall 1.

Battery integrated cabinet assembly tutorial diagram

With inspections and testing performed on every part of the cabinet including structural, finish, and drawer and door operations, our cabinets have continued to meet or exceed industry

Emergency cabinet battery assembly method

The electric motorcycle battery pack can be used in the battery swapping cabinet, with the popularity of electric motorcycles, charging the battery becomes a problem, either because the

Eaton xStorage 250 1000 kW BESS Installation and

May 27, 2025 · IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS This manual contains important instructions that you should follow during installation and

USER''S AND INSTALLATION GUIDE

Jul 2, 2025 · Battery cabinet internal power wiring, Battery-to-UPS power wiring and control wiring for integral line-up and match battery cabinets are supplied with both the small and large

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Eaton Power Xpert 9395

Sep 7, 2024 · The 9395 battery cabinet is designed to use with the 9395, 9395P, and 9395C. The primary difference is the 9395C uses an Under Voltage Relay instead of a Shunt Trip device to

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Connect a battery-to-battery cable to Connector B on the first cabinet in the previous string, and to Connector A on first cabinet in the additional string. Connect the

PDU8000 电池柜-T 快速指南 (02405362)

Jun 18, 2019 · 本文档主要介绍电池柜安装和调试的操作方法。2 Tools / 安装工具 4 Installing a Battery Cabinet / 安装电池柜 PDU8000 Battery Cabinet-T Quick Guide 4.1 Checking Before

Microsoft Word

Jul 3, 2023 · 9.9.2 Connections (J4) for a cabinet with external BS-210 and no external panel bus If the Operator Panel BS-210 is to be placed outside a cabinet, and no external panel bus (with

10 sets of lithium battery assembly instructions

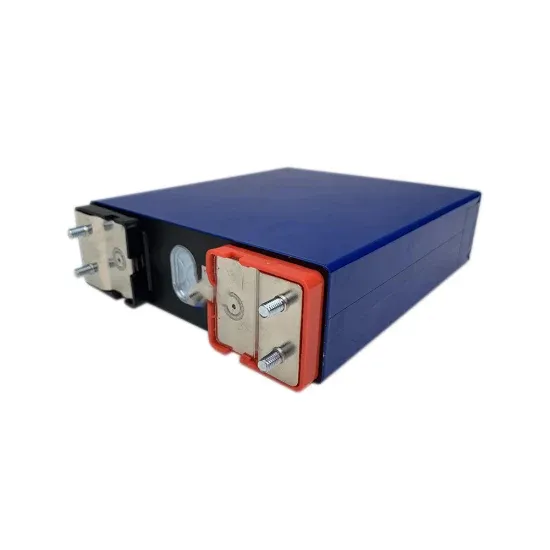

battery cells into sets called battery modules. These modules are then assembled to create a battery pack, whi ttery Cabinet Installation and Operatio Manual. Date: August 30 2023| T pe:

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Procedure Refer to Figure 3 and install the 19" or 23" relay rack mounting angles to the battery cabinet. Mounting hardware is provided with the battery cabinet. Use a provided

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Each battery string is made up of two battery cabinets that are connected to the UPS in parallel. Connect a single battery cabinet system. Refer to the illustration, "Cabling 3U

6 FAQs about [2 sets of 18 battery cabinet installation]

How do I mount a battery cabinet?

The battery cabinet is designed to mount in a standard 19” or 23” wide relay rack or on a wall. Refer to Figure 3 and install the 19” or 23” relay rack mounting angles to the battery cabinet. Mounting hardware is provided with the battery cabinet.

Where can a battery cabinet be installed?

Ranging in 300 to 400mm deep they are suitable for installation in walkways, sides of buildings, alongside industrial equipment and areas with limited space. The cabinets come pre-wired with all interconnecting battery cables and a DC busbar for easy indoor or outdoor installation of our batteries.

How many P series batteries can be installed in a cabinet?

DC isolator, main DC busbar and all interconnecting battery cables are provided and should installed to suit your layout inside the cabinet. Up to 6 P Series batteries can be installed on the lower shelf, and an additional 6 P series batteries on the upper shelf.

How do you connect a battery cabinet to a power system?

Connect the power system’s battery cable terminated in an Anderson connector to the first battery cabinet’s battery cable terminated in a mating Anderson connector. Connect the second battery cabinet’s battery cable terminated in an Anderson connector to the fixed mating Anderson connector located on the first battery cabinet.

What is a battery cabinet?

The battery cabinet contains one (1) 40 A battery disconnect circuit breaker and provides alarm leads attached to the common contacts of the breaker. Battery cabinets may be daisy chained as shown in Figure 7 to increase the reserve time.

How do I install a battery storage system?

install battery storage systemsINSTALL YOUR SYSTEMThe first thing to do when having a battery storage system installed is to ask to see the instal er’s Clean Energy Council Accredited Installer card. This shows that the install

Learn More

- Battery cabinet installation details ESS power base station

- UPS battery cabinet c1 installation

- Liquid-cooled energy storage battery cabinet installation in Portugal

- Smart rechargeable battery cabinet installation site

- Centralized battery cabinet installation site

- Lima Outdoor Communication Battery Cabinet Installation Company

- C40 Battery Cabinet Installation

- Installation specification requirements of battery cabinet in computer room

- Buenos Aires Cabinet Battery Cabinet Installation Training

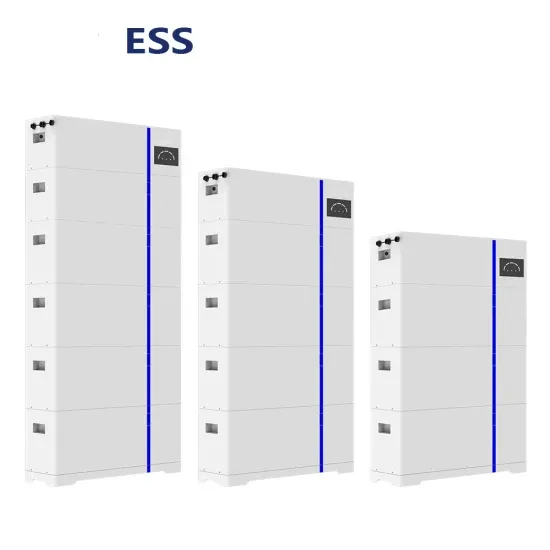

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

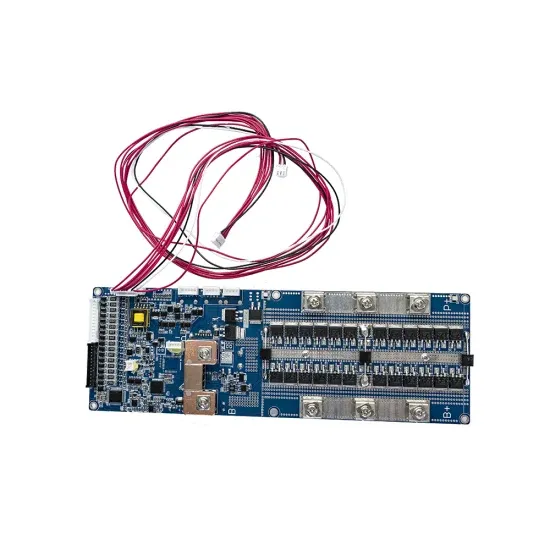

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.