Delamination of components for recovery of waste

Jan 15, 2025 · Tempered glass, EVA, backsheet, fluorinated coating, and solar cell are delaminated from each other. The rapid development of the photovoltaic industry inevitably

EoL pathways for PV backsheet

Jan 21, 2022 · A PV backsheet as shown in Figure 2-1 is the outermost layer of the PV module, which acts as a protective layer to shield the inner components of the module, in specific the

What is a Photovoltaic Module? A Comprehensive Definition

Jul 16, 2025 · Understanding the Design and Efficiency of Photovoltaic Modules Understanding the photovoltaic module definition is crucial for homeowners, as the design of photovoltaic

Effectively and completely separating the waste crystalline

Jun 22, 2025 · However, PV modules also contain elements that may negatively impact the environment, such as lead in soldering materials [9], cadmium [10], and fluorine in the

#Bifacial_photovoltaic (PV) modules are a type of solar panel

Jun 18, 2025 · The mechanism of hashtag #bifacial_PV_modules involves several key components and processes: ️ Front-side solar cells: Bifacial PV modules contain solar cells

The Influence of Soldering Flux on Stability of

Feb 4, 2025 · This concern gains further significance as current HJT cells are predominantly encapsulated between glass sheets and POE or thermoplastic polyolefin (TPO) on both sides

This Is How PV Bill of Materials Impacts Module Production

Aug 13, 2024 · Generally, the outer layer should contain fluorine. The middle layer: Acts as a support layer and requires resistance to both high and low temperatures, stable mechanical

Flash separation and recovery of each component from waste photovoltaic

Jun 1, 2025 · PV modules contain tempered glass, adhesive films, and valuable metals such as silver, aluminum, silicon, lead, and tin, making their recycling both environmentally and

APPLICATION OF FLUORINE MATERIALS FOR SOLAR CELL

Solar PV ModuleSolarPV moduleA solar PV module is a device in which several solar cells are connected toget m2,Cell efficiency - 10 to 25% )• This power is not enough for home lig

Structure and basic properties of photovoltaic module

Jan 1, 2016 · Introduction To take advantage of renewable photovoltaic energy it is essential to have capable photo electronics properly protected against environmental factors like climate or

EoL pathways for PV backsheet

Jun 20, 2022 · Fluoropolymers in PV modules are largely made of polyvinylidene fluoride (PVDF) or polyvinylfluoride (PVF) also known as Kynar® and Tedlar® respectively. The presence of

#Bifacial_photovoltaic (PV) modules are a type of solar

The mechanism of #bifacial_PV_modules involves several key components and processes: ️ Front-side solar cells: Bifacial PV modules contain solar cells on both the front and back sides

Green recycling of end-of-life photovoltaic modules via

Nov 1, 2024 · Abstract Sustainable End-of-life (EOL) photovoltaic (PV) modules recycling is essential for achieving resource conservation and alleviating environmental issues. Ethylene

Degradation Processes and Mechanisms of Backsheets

Jan 1, 2019 · Packaging in c-Si PV modules is typically comprised of a glass superstrate, two layers of encapsulants placed on both sides of the cell and electrical connections, and a

#Bifacial_photovoltaic (PV) modules are a type of solar panel

The mechanism of #bifacial_PV_modules involves several key components and processes: ️ Front-side solar cells: Bifacial PV modules contain solar cells on both the front and back sides

Green separation and decomposition of crystalline silicon photovoltaic

Apr 30, 2024 · Abstract The treatment and recycling of discarded crystalline silicon photovoltaic modules (c-Si PV modules) has become a research focus, but few research have paid

The Influence of Soldering Flux on Stability of

Feb 3, 2025 · The testing method presented in this study offers significant benefits to PV manufacturers producing glass/glass modules with POE encapsulants

Fluoropolymer films in the photovoltaic industry

Aug 1, 2004 · New photovoltaic technologies such as thin film will put even greater demands on the packaging materials. Fluoropolymer films have played and continue to play multiple roles

Effects of solar photovoltaic technology on the

Oct 1, 2017 · The negative effects of solar photovoltaic system production include wastewater and waste gas pollutions, the representatives of which contain

FLUORINATED GREENHOUSE GASES IN PHOTOVOLTAIC

Nov 2, 2007 · Some fluorinated gases (F-gases) which are used, or considered to be used, in crystalline silicon photovoltaic solar cell and film silicon module manufacturing have a very

6 FAQs about [Photovoltaic modules contain fluorine on both sides]

What is a PV module based on?

For some historical context, early PV modules used backsheets based on an FPF structure, with the core PET layer sandwiched between 2 fluoropolymer layers. The fluoropolymer here is nothing but the proprietary polyvinyl fluoride (PVF), commercially known as Tedlar, popularized by DuPont, the well-known US-based chemical giant.

Can a photovoltaic backsheet be chemically recycled for fluoropolymer recycling?

In this study, we investigated the feasibility of chemically recycling a fluorine-containing photovoltaic (PV) backsheet for fluoropolymer recycling.

Are fluorine-free backsheets better than fluorinated pyrolysis?

Likewise, in the pyrolysis scenario, fluorine‐free backsheets show better environmental performance than fluorinated backsheets in 8 out of 12 impact categories. Pyrolysis could be a potential end-of-life treatment option for fluorine-free backsheets.

Can fluoropolymers be recycled from end-of-life PV backsheets?

Fluoropolymer recycling could be achieved by melting and extruding the recovered fluoropolymers, which in turn could be used to produce new fluoropolymers. Furthermore, we proposed a potential fluoropolymer recycling scheme from end-of-life PV backsheets.

What is a fluoropolymer?

The fluoropolymer here is nothing but the proprietary polyvinyl fluoride (PVF), commercially known as Tedlar, popularized by DuPont, the well-known US-based chemical giant. Such a backsheet structure was often referred to as TPT, which was also the first backsheet composition used for PV module applications.

Do fluorine-free backsheets improve environmental performance?

The life cycle assessment for the fluorine-free backsheets show better environmental performance compared to the fluorinated backsheets in both incineration as well as the pyrolysis EOL scenarios.

Learn More

- Ultra-white solar glass photovoltaic modules

- Vienna double-glass photovoltaic modules

- Ngerulmud Distributed Solar Photovoltaic Modules

- Glass the main material of photovoltaic modules

- Tirana double glass photovoltaic modules

- Huawei s all-black shingled photovoltaic modules

- Can stacked photovoltaic modules be used

- Project Implementation Plan Photovoltaic Modules

- Differences between single-sided and double-sided photovoltaic modules

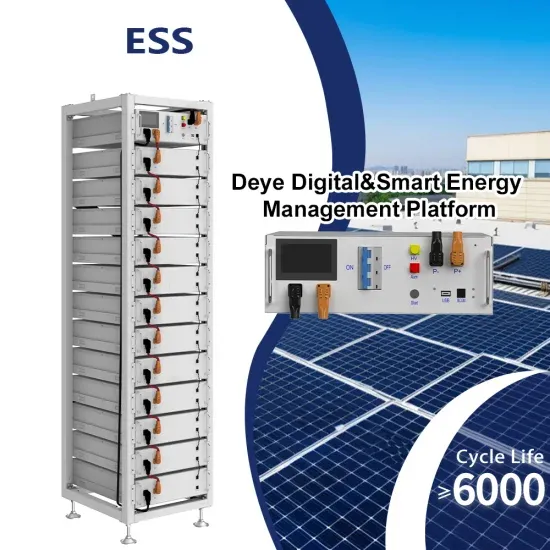

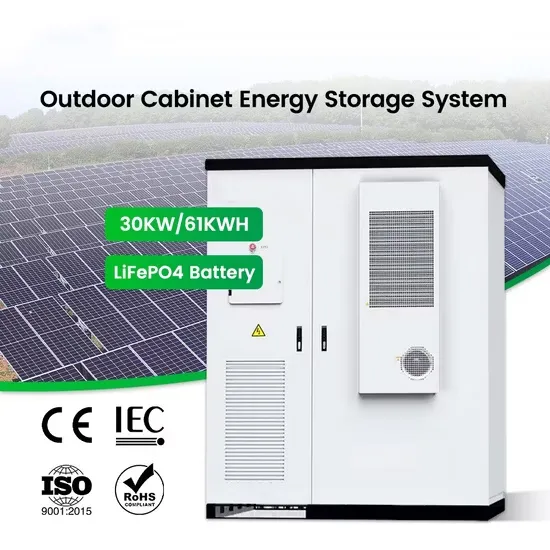

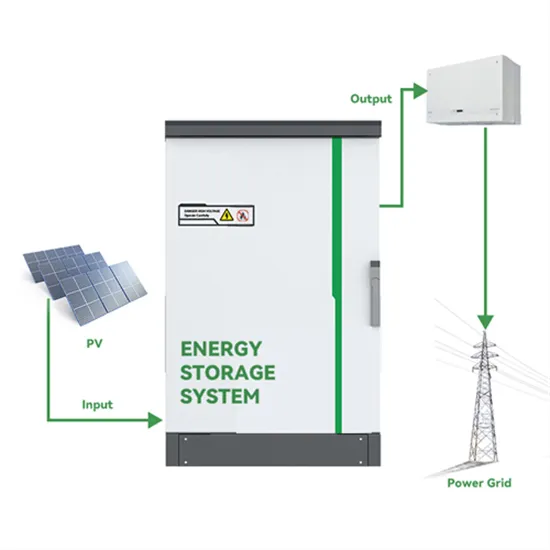

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.