Test Method For Waterproof And Air Tightness Of Energy Storage

Jan 3, 2025 · Applicable scenarios: This method has extremely high accuracy and is suitable for energy storage battery systems that require high waterproof and airtightness, such as energy

Lithium Battery Storage Container

2 days ago · Discover Polystar''s cutting-edge solutions for energy storage systems and lithium-ion battery storage. Our fire-rated lithium battery storage containers and comprehensive safety

Certified for Safety: How TLS Energy Storage Containers

Jul 21, 2025 · As the global installed capacity of renewable energy continues to surge, energy storage systems have become a critical pillar for ensuring power grid stability and flexibility.

Trina Storage Successfully Passes Fire Test, Demonstrating

Nov 13, 2024 · The test simulated real-world fire conditions to assess the effectiveness of Trina''s comprehensive safety measures. The test referenced a range of international standards,

Protection Standards And Requirements For Energy Storage Containers

Apr 10, 2025 · Purpose of Energy Storage Container Protection Standards Preventing fire and explosion: Energy storage containers usually store a large number of energy storage devices

Energy Storage Container Test Solutions: Your Guide to

As the global energy storage market balloons to $33 billion annually [1], proper testing has become the unsung hero of this clean energy revolution. Whether you''re working with lithium

WATERPROOF TESTING OF BESS CONTAINERS

The IEC62933 series certification is a core standard system recognized globally in the energy storage industry, covering strict requirements for energy storage systems in terms of safety,

Key Design Considerations for Energy Storage Containers

Apr 11, 2025 · The design of energy storage containers involves an integrated approach across material selection, structural integrity, and comprehensive safety measures. Choosing the right

Energy Storage Container Fan Power: The Unsung Hero of

Oct 24, 2024 · The Hidden Costs of Poor Fan Selection Imagine this scenario: A 2024 grid-scale storage project in Arizona had to replace 80% of its fans within 18 months due to dust

What tests should be done on energy storage containers?

May 12, 2024 · The outlined evaluations for energy storage containers—performance tests, safety assessments, environmental impact evaluations, and maintenance inspections—are

Energy storage container waterproof test

By simulating extreme environmental conditions, TLS Energy International can identify potential vulnerabilities and address them before the containers are deployed in the field. The water

Energy storage cabinet waterproof test solution

Expand your energy storage easily with 1 Atlas 16.73"x 25.82"x33.85" Waterproof cabinet from 5kwh to 22.8kwh quickly and easily with Atlas slim & arrow Powerwalls.

Energy storage container rain test

Global Overview of Energy Storage Performance Test Protocols This report of the Energy Storage Partnership is prepared by the National Renewable Energy Laboratory (NREL) in collaboration

WATERPROOF TESTING OF BESS CONTAINERS

Testing standards for container energy storage batteries Before transportation, lithium battery packs of the UN3536 category must pass the UN38.3 test and undergo a series of safety tests,

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

HiTHIUM Compeletes the the World''s First All Open-Door

June 5, 2025, Xiamen, China - HiTHIUM, a leading global energy storage technology company, has completed the world''s first all open-door large-scale fire test of its ∞Block 5MWh battery

Energy storage cabinet waterproof test

The interior of the cabinet is lined with heat-resistant ceramic material (temperature resistance: 1260 ºC),which can effectively prevent the fires from spreading and burningwhile also

FIRE AND EXPLOSION PROTECTION FOR BESS

Jan 9, 2024 · The NFPA 855 standard, which is the standard for the Installation of Stationary Energy Storage System provides the minimum requirements for mitigating the hazards

Battery Energy Storage Container Waterproof Glue: The

A $500,000 battery energy storage container fails during a storm because waterproof glue peeled off like old wallpaper. Sounds like a bad joke? Unfortunately, it''s a real-world problem. As

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

Envision Sets Record with 49-Hour Fire Test in Energy Storage

Jul 4, 2025 · Envision Energy demonstrates unparalleled BESS resilience and environmental safety in a 49-hour test, setting a new fire safety standard.

Water Spray Test in BESS Container Production by TLS Energy

Aug 23, 2024 · Explore how TLS Energy International conducts rigorous water spray testing on their BESS containers to ensure maximum durability and safety in harsh environments. Learn

6 FAQs about [Energy storage container waterproof test]

Why is waterproof testing important for Bess containers?

One crucial aspect of BESS containers is their waterproofing, as it directly impacts the durability, safety, and performance of these energy storage units. In this article, we will delve into the importance of waterproof testing for BESS containers and its implications for the renewable energy sector. The Significance of Waterproof Testing

Why is waterproof testing important?

Waterproof testing of BESS containers is a critical step in ensuring the safety, durability, and performance of energy storage systems. As the renewable energy sector continues to grow, maintaining the reliability of BESS units becomes paramount.

What is a water spray test at TLS Energy International?

By simulating extreme environmental conditions, TLS Energy International can identify potential vulnerabilities and address them before the containers are deployed in the field. The water spray test at TLS Energy International involves subjecting the BESS container to controlled water spray under various pressures and angles.

What is a water spray test?

TLS Energy International, a leader in the design and manufacture of BESS containers, integrates thorough testing procedures into their production process to ensure that each product meets the highest standards. Among these tests, the water spray test stands out as a key method for verifying the container’s ability to resist water ingress.

How does a Bess enclosure prevent water infiltration?

The enclosure's ability to prevent water infiltration is assessed based on visual observations and measurements. Pressure Chamber Test: This advanced method involves subjecting the BESS container to varying degrees of air pressure while monitoring for any water leaks.

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) have gained significant attention as a key component of the transition towards sustainable energy solutions. These systems play a pivotal role in stabilizing the electrical grid, integrating renewable energy sources, and providing backup power during grid outages.

Learn More

- Hargeisa Energy Storage Container Project

- Introduction to energy storage container processing companies

- Suriname Energy Storage Container Overseas

- Mali integrated energy storage container 5g base station

- ASEAN container mobile house energy storage box

- What kind of battery is the energy storage container battery

- Belize Energy Storage Container House Design

- Peruvian iron-lithium battery energy storage container supplier

- Quito Energy Storage Container 6 25MWh

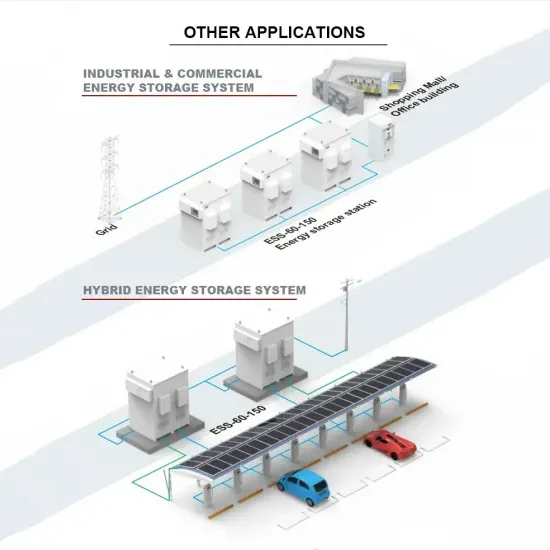

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.