AUTOMATIC SOLAR TRACKING SYSTEM

May 26, 2022 · Objective of Study The project aims to utilize maximum solar energy through solar panels. For this, a digital-based automatic sun tracking system and MPPT circuit are being

How to install fully automatic solar | NenPower

Apr 17, 2024 · A fully automatic solar system comprises several key components, each playing an essential role in the effective harnessing of solar energy. The

Tower Concentrating Solar Power System

The Heliostat Field Auto-cleaning System, which is developed by Cosin Solar, is able to carry out periodical cleaning during operation of the plant. The system automatically monitors the

Automatic Solar Tracking System for Maximum

Sep 3, 2024 · Automatic solar trackers help solar panels follow the sun, making them more efficient. There are different types of solar trackers, including single

Automatic Solar Panel Cleaning System Machine

Apr 4, 2025 · Discover Solabot Technologies – India''s top provider of Automatic Solar Panel Cleaning System Machine for efficient, waterless solar maintenance.

Startup Charge Robotics ⚡ Autonomous Robot

Mar 12, 2025 · With its fully automatic "Sunrise" system, the innovative start-up Charge Robotics has developed a groundbreaking solution that revolutionizes

Todos Launches Water-Free Fully Automated Solar Panel Cleaning System

Apr 2, 2025 · In the context of accelerating global energy transition, the Todos brand has launched a revolutionary product: the Automatic Solar Panel Cleaning Machine. This water

SAUT Fully Automatic Solar Tracking System | Dual-Axis

SAUT Fully Automatic Solar Tracking System is an all-weather dual-axis automatic positioning platform designed for solar radiation monitoring instruments. It is widely used in solar

AUTOMATIC SOLAR TRACKING SYSTEM

May 26, 2022 · II. METHODOLOGY Implementation The project called "Automatic Solar Tracking System" is produced through the installation of the various nitty-gritty such as a solar panel

Sunpure Technology_robotic cleaning_solution provider

Sunpure specializes in PV intelligent cleaning robot business, providing fully automatic, semi-automatic, railed, trackless cleaning robots and intelligent robot shuttle for utility and C&M PV

Sunpure Technology_robotic cleaning_solution provider

Its core product portfolio includes full-scenario PV cleaning robots—covering railed, trackless, and intelligent shuttle —as well as PV module fitting robot. Sunpure is committed to solving the

Automatic solar panel cleaning robot manufacturer

In 2018, in response to the custom demand for automatic cleaning of solar power plants from an energy company, we began producing solar cleaning machines. Today, the latest version of

Smart Hybrid Fully Automatic Solar Grass Cutter

Jun 5, 2023 · Automatic grass cutters have been developed to solve the problem of maintaining large areas of grass manually. The fully automated solar grass cutter is a fully automated

Automatic Sun-Tracking System

Sep 12, 2020 · Hence, alternative sources of energy have become the desired solution for a prosperous future and a clean environment. Thus, solar energy is considered one of the most

Fully Automatic Solar Tracking Monitor Solar Tracking System

10°~90° Horizontal Running Angle -120~+120° (adjustable) Fully Automatic Tracking System Two-dimensional tracking drive mode Application Solar PV power station, agriculture, forestry,

15KV USB DC Double Power Solar Zatka Machine, For Farm, Fully Automatic

Manufacturer of Solar Fence System - 15KV USB DC Double Power Solar Zatka Machine, For Farm, Fully Automatic offered by Computer Carnival, New Delhi, Delhi.

Autonomous Robotic Mounting System for Solar Panel

The SolarARMS project represents a groundbreaking advance in renewable energy technology, with a laser focus on optimizing solar panel installations. This initiative is set to introduce an

China Best SAUT Fully Automatic Tracking System

With the increasing demand for solar monitoring accuracy, the SAUT fully automatic dual-axis solar tracking system came into being. This is a highly integrated, intelligently controlled, all

6 FAQs about [Fully automatic solar system]

What is automatic solar tracking system?

e t II.METHODOLOGYImplementationThe project called "Automatic Solar Tracking System" is produced through the installation of the various nitty-gritty such as a solar panel that provides 12 volts as output, a NodeMcu as MCU, a motor driver – with IC L293D, two LDR sensor modules, a 10 r.p.m. simple DC motor, a c

How does the robotic solar panel cleaning system work?

Fast charging. The robotic solar panel cleaning system is equipped with a dedicated charging management circuit that supports the MPPT maximum power point tracking charging algorithm. After executing the task, the lithium battery is quickly charged through a photovoltaic panel, with a maximum recovery time of 2 hours.

Why should we use automated cleaning robots for solar panels?

The cleaning frequency of solar panels significantly impacts power generation efficiency in arid regions such as the Arabian Peninsula and northern and eastern India. To mitigate the adverse effects of dust pollution on power generation, we recommend using automated cleaning robots.

Which motor is used in a solar system?

Actuators and motors are the muscles of the system. They move the solar panels to follow the sun’s path. Stepper motors and servo motors are often used because they provide precise control. The choice between these motors depends on the system’s requirements for accuracy and power consumption.

How do solar panels work?

Light Dependent Resistors (LDRs) are commonly used as sensors. These sensors send signals to a microcontroller, which then processes the data and sends commands to the motors to adjust the panel’s angle. Actuators and motors are the muscles of the system. They move the solar panels to follow the sun’s path.

Can a solar tracking system boost solar panel efficiency?

Installing a solar tracking system can be more complex than setting up stationary panels. It involves site selection, mounting, calibration, and testing. However, the increased efficiency and energy output can make it worthwhile. Learn how automatic solar tracking system can boost solar panel efficiency by aligning with the sun's movement.

Learn More

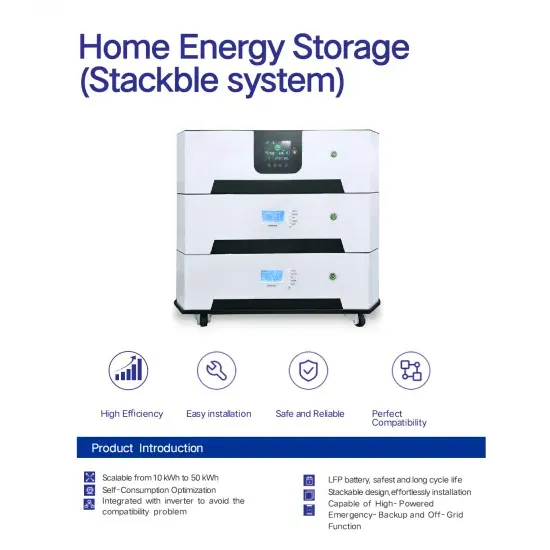

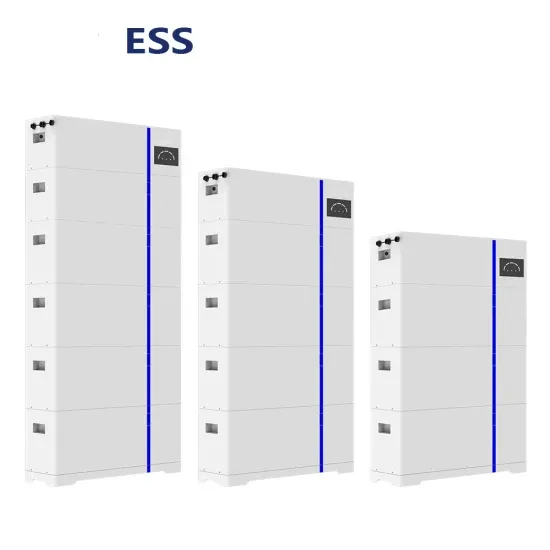

- Fully automatic production of energy storage containers

- Fully automatic power private network base station design

- Solar automatic tracking lithium battery charging system

- Solar energy monitoring automatic tracking system

- Principle of Solar Automatic Charging Container

- Fully solar air conditioning by 2025

- Household solar water pump drip irrigation

- Building wind and solar complementary hardware for communication base stations

- Solar cycle energy storage cabinet replacement price

Industrial & Commercial Energy Storage Market Growth

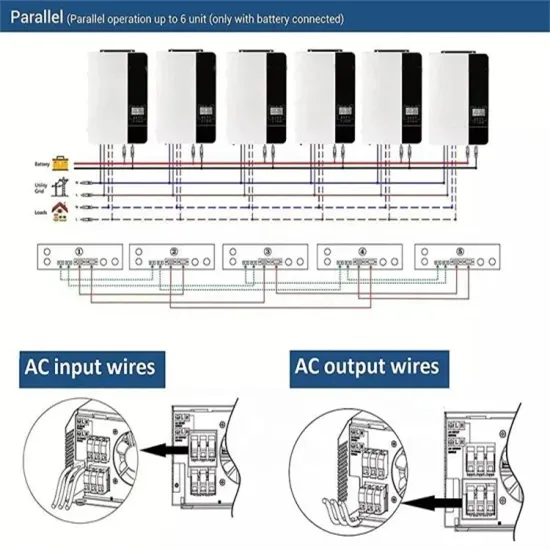

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

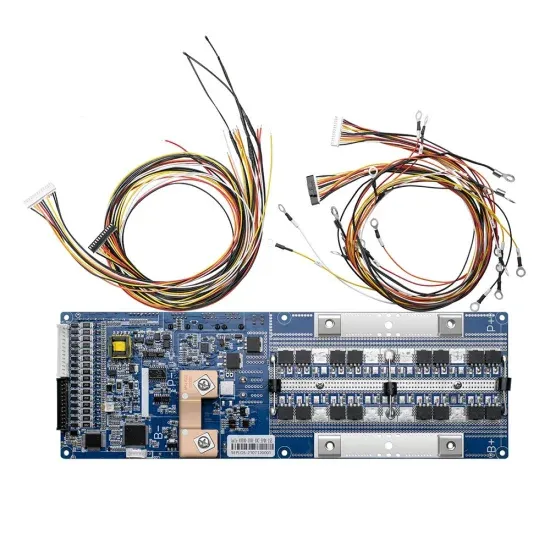

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.