CH 9 ENG ELECTRICAL Equipment Flashcards | Quizlet

A. Rotating armature B. Rotating field C. Stationary armature D. Stationary field, What is the generator voltage aboard the landing craft air cushion vehicle? A. 120/208 B. 208/450 C.

Section 9.4 Electric Power Generation

Jan 19, 2005 · ooling towers near some power plants? How does a power plant determine how much power it needs to generate, and what happens to its generators when the demand for

How fast does a generator have to spin to produce electricity?

Dec 26, 2020 · How does a generator work to create electricity? It is important to understand that a generator does not actually ''create'' electrical energy. Instead, it uses the mechanical energy

How many volts does the generator in a powerplant create?

Apr 18, 2020 · How are generators rated in Watts and kilowatts? Generators are rated in Watts or Kilowatts to express how much work they can do. Just as an athlete might put out a burst of

What is the engines speed? What are engine revs? Can you

The faster the engine runs, the more complete rotations it does per minute and the more power it produces. For a diesel generator, the engine normally runs at a fixed speed. 1500 revolutions

HOW ELECTRICITY IS PRODUCED AT A COAL-FIRED

Aug 24, 2021 · INTRODUCTION In South Africa, most of the electricity comes from thermal power stations, fuelled by coal. Most of these coal-fired stations consist of six generating units. Each

How Generators Work & Produce Electricity

Mar 9, 2025 · For two poles (P=1): F=RPM/60, that is for 60Hz the shaft has to spin at 3600 revolutions per minute. That''s how most conventional home generators operate. Note that

How many revolutions does a wind turbine generator make

As the photovoltaic (PV) industry continues to evolve, advancements in How many revolutions does a wind turbine generator make per second have become critical to optimizing the

2. Generator Basics IEEE

Sep 27, 2016 · • Most modern, larger generators have a stationary armature (stator) with a rotating current-carrying conductor (rotor or revolving field). As the PMG rotor rotates, it

What mechanical revolution is measured in "RPM"?

Jul 14, 2025 · I do realize that it stands for revolutions per minute, but what are the revolving pieces that are measured? Assuming it is the crankshaft, is RPM

How Large Electric Power Generators Work: The Basics

Mar 7, 2024 · Large generators produce electricity at 20,000 volts, smaller generators output at 400 volts or 6000 volts. These voltages are "stepped up or down" as required for transmission

What RPM Should a Generator Run At?

Dec 11, 2023 · 1800 RPM generators are generally quieter, more durable, and fuel efficient, making them ideal for continuous, long-term use in industrial applications or off-grid living

6 FAQs about [How many revolutions does the power station generator have ]

How much power does a generator produce?

The RPM dictates how fast the generator’s engine turns and, in turn, how much power the generator produces. A portable generator should run at 3600 RPM with two poles, giving it a 60 Hz output, and larger generators run at 1800 RPM with four poles, producing 60 Hz. The rotational speed and number of poles determine the output frequency.

What are 1800 & 3600 RPM generators?

So, let’s get right down to the mystery of 1800 and 3600 RPM generators. RPM, or revolutions per minute, is a measure of how fast a generator engine rotates. RPM directly affects the generator’s power output, frequency, noise level, lifespan and fuel efficiency.

What does rpm mean on a generator?

RPM stands for revolutions per minute and measures how fast a generator’s engine is running. The RPM determines the power output of a generator, with higher RPMs producing more power than lower RPMs. Additionally, the generator’s RPM dictates how much fuel a generator uses.

What rpm should a portable generator run?

A portable generator should run at 3600 RPM with two poles, giving it a 60 Hz output, and larger generators run at 1800 RPM with four poles, producing 60 Hz. The rotational speed and number of poles determine the output frequency. Picking the right RPM ensures efficiency and prevents premature wear.

What volts does a generator produce?

Voltage: this is the main electromotive force that drives the electric current. Large generators produce electricity at 20,000 volts, smaller generators output at 400 volts or 6000 volts. These voltages are “stepped up or down” as required for transmission and distribution to the user.

What wattage should a generator run?

Determine the total wattage required by all the appliances or equipment you plan to run on the generator. If your power needs are high, a 3600 RPM generator might be more suitable. Conversely, for lower power requirements, an 1800 RPM generator should suffice. Your budget: Different RPMs come with other price points.

Learn More

- How many kilowatts does the generator set of Kuala Lumpur Power Station have

- How does Eritrea s telecommunications BESS power station charge

- How to connect the capacitor of base station power cabinet

- How many stations are there in Congo s power base station

- How is the photovoltaic power generation of the Tehran communication base station inverter

- Generator Wind and Solar Power Station

- Permanent magnet generator power station

- BESS a generator for the Sino-European rainproof power station

- How big is a 1 megawatt power station

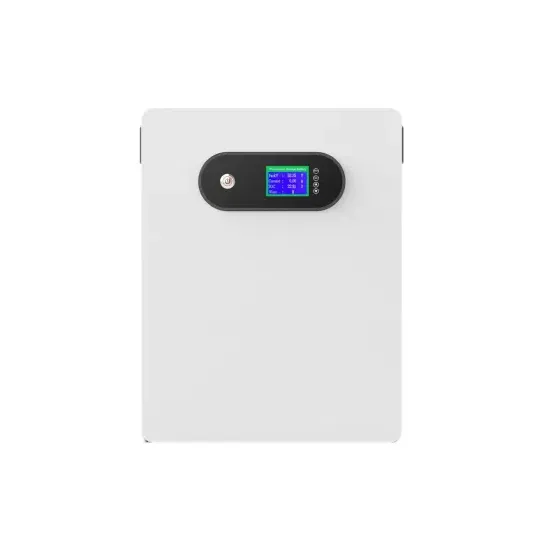

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

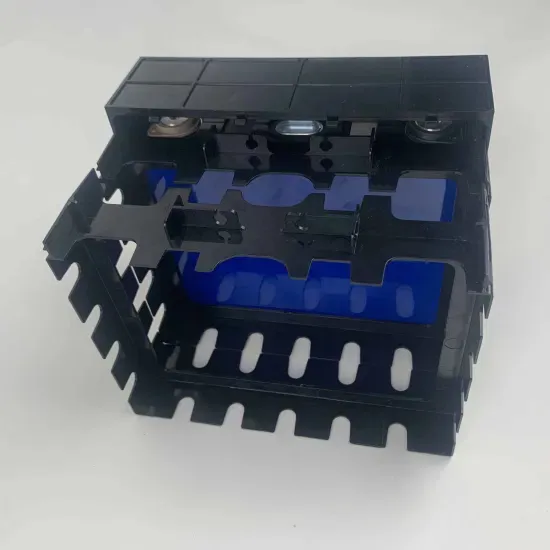

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.