Can I Replace a Capacitor With a Higher µF? | Is

In some cases, a capacitor can be replaced with a higher µF. It depends on the function of the capacitor in the circuit. It is critical to first determine the function

Capacitor voltage effects a tone circuit pot sweep?

May 14, 2023 · I came across the contention today (online) that if we compare two capacitors of equal value (say .022mfd) and one has a voltage rating of 400V,

Capacitor''s influence on tone?

Mar 31, 2003 · With the tone knob fully open it doesn''t matter. It affects the treble signal when you started rolling the tone off. The value of the cap means how much treble gets rolled off. How

The effect of Tone Capacitors | GuitarNutz 2

Jan 21, 2024 · It is for a guitar with a single coil pickup and two 250k pots for tone and volume, testing the most common range for tone caps of between 0.01 and 0.047uF (10nF to 47nF).

The Effect of Cable Capacitance on Guitar Tone

The graph shows the frequency response of a guitar in three situations: 1) no cable at all (green), 2) 16 foot cable with 480pf capacitance (blue), and 3) 35 foot same cable with 1040pf

Capacitors Demystified: Why They Matter for Guitar Tone

Aug 14, 2025 · The main use of capacitors involves tone controls, but they also appear in treble bleed circuits located on volume pots. Reducing the volume control causes treble frequencies

The Truth about Tone Capacitors | Atlantic Quality Design,

We used a Fender Stratocaster with a single coil bridge position pickup to perform these tests. We selected a single coil pickup because the lower interwinding capacitance and inductance of the

Understanding the role of capacitors in guitar tone

Feb 18, 2025 · How Capacitors Influence Tone The main job of a capacitor in your guitar is to work alongside the tone pot (short for potentiometer) to adjust your

All you need to know about capacitors in guitar pedals

Aug 2, 2025 · Most of the capacitors we are going to use are microFarad (µF), nanoFarad (nF) or picoFarad (pF). 1 µF = 1,000 nF = 1,000,000 pF. Usually, when building guitar pedals, we use

The effect of Tone Capacitors | GuitarNutz 2

Jan 21, 2024 · JohnH Global Moderator Premier MasterMind!! Posts: 6,427 Likes: 398 The effect of Tone Capacitors Feb 19, 2014 2:47:18 GMT -5 RamonDoReMi, atherisinnovations, and 2

Understanding the role of capacitors in guitar tone

Feb 18, 2025 · Changing the capacitor can significantly affect your guitar''s tone, allowing you to achieve a sound closer to your ideal. What is a capacitor''s role

6 FAQs about [The influence of super farad capacitor on tone]

What is the value of a tone capacitor in a guitar?

A common value for a tone capacitor in guitars is 0.022 microfarads, or 0.022uF as an abbreviation. A larger value that rolls off high frequencies to a greater degree is 0.1uF. There are many values used in the wide range of guitars on the market, but the tests here focus on these two values. The principles learned apply to other values as well.

Can you put a capacitor inside a guitar?

Now you won’t be able to fit your handmade capacitor inside your guitar, but there are mass produced capacitors that fit nicely, and change the tone of your instrument by rolling off the high frequencies, in conjunction with the guitar’s tone pot.

Are tone capacitors directional?

To head off another subsidiary hypefest that pops up periodically, some say that tone capacitors are directional. That is, they have two wires and the two different ways of connecting them results in tonal differences. Now some capacitors are directional. The term is polarized.

Why do capacitors sound different when wound of foil?

When a capacitor is wound of foil, naturally one side of the metal sandwich is on the outside of the finished part. It has been noted that this outside foil can pick up noise and change the sound of a capacitor. This is simply and indication that the rest of your circuit is poorly shielded!

Are tone caps polarized?

The term is polarized. For example, the electrolytic capacitors used in the power supply of your tube amp are polarized. Connect one of those backwards and you will have a mess on your hands. But for tone caps of the type we tested, there are no polarity issues. The capacitors function and sound the same whichever way they are connected.

What are filter capacitors used for in guitar pedals?

Filter capacitors are used in guitar pedals to filter the power supply voltage (such as 9V or 5V after a regulator) and reduce noise. They are often electrolytic capacitors with large values, like 100 µF, and are commonly found in guitar pedals.

Learn More

- Namibia s official super farad capacitor

- 27v super farad capacitor

- Monrovia Super Farad Capacitor

- Super Farad capacitor structure

- Test installation of super farad capacitor

- Rabat Super Farad Capacitor Supplier

- 24V Super Farad Capacitor

- Lisbon Super Farad Capacitor Brand

- E-speed super farad capacitor

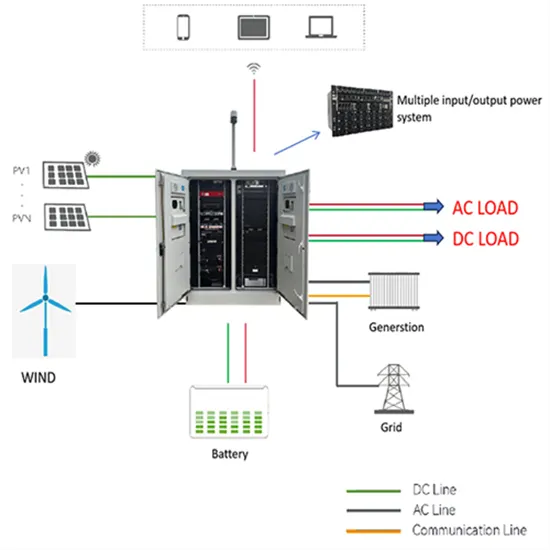

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.