Testing and measurement techniques for supercapacitors

Jan 1, 2023 · The commonly used testing methods for supercapacitor parameter evaluation include cyclic voltammetry (CV), galvanostatic charge/discharge (GCD), and electrochemical

Step-by-Step Guide: How to Install a Capacitor

Feb 19, 2025 · Test the capacitor''s function and performance after installation to ensure everything is working correctly and efficiently. By following these

Supercapacitor Technical Guide

Feb 23, 2024 · Supercapacitors are ideal for applications ranging from wind turbines and mass transit, to hybrid cars, consumer electronics and industrial equipment. Available in a wide

Testing Super-Capacitors Part 1: CV, EIS, and Leakage

Sep 5, 2022 · Testing Super-Capacitors Part 1: CV, EIS, and Leakage Current Introduction Super-capacitors are energy storage devices similar to secondary batteries. Unlike batteries, which

Super farad capacitor energy storage

Its high capacitance and low voltage make it an ideal solution for energy storage. Installation and Buy 2.7V 500F Capacitor Farad Capacitor 35mm 60mm, Super Capacitor Drops Automobile

Farad Super3 Power Supply Reviews

3 days ago · The Farad Super3 Power Supply is a double regulated 3A super capacitor linear power supply (LPS). With the latest of capacitor technology, it brings great improvement to any

How to Test the Quality of Super Farad Capacitors?

Jun 7, 2022 · When people buy super farad capacitors, they are more concerned about whether the quality of the product is qualified, because only when the product with qualified quality is

White Paper Testing Super-Capacitors

Sep 5, 2022 · Introduction Super-capacitors are energy storage devices similar to secondary batteries. Unlike batteries, which use chemical reactions to store energy, super-capacitors

Testing and measurement techniques for supercapacitors

Jan 1, 2023 · The testing techniques for supercapacitors due to high specific capacitance require constraints like time constants and as such require suitable adaptations and modifications of

White Paper Testing Super-Capacitors

Sep 5, 2022 · Current applications for super-capacitors include: Hybrid electric vehicles (HEVs) Diesel-engine starting systems Cordless power tools higher power than the battery alone. For

How to Test the Quality of Super Farad Capacitors?

Jun 7, 2022 · People want to know the quality of super Farad capacitor, so they generally need to rely on professional measuring instruments for testing. Before we leave the factory, there will

6 FAQs about [Test installation of super farad capacitor]

How to test a supercapacitor based on a high specific capacitance?

The testing techniques for supercapacitors due to high specific capacitance require constraints like time constants and as such require suitable adaptations and modifications of the conventional techniques and instrumentation to yield desired estimations.

How do you test a super capacitor?

leads to one side of the capacitor. Connect the working electrode lead (and working sense es a current given by=I is current= = in amperes, and s the scan rate of the voltage ramp.Voltage scan rates for super-capacitor testing ar usually between 0.1 mV/s and 1 V/s. Scan rates at the lower end of this range allow slow processes to occur, bu

How do you measure the capacitance of a supercapacitor?

Supercapacitors have such large capacitance values that standard measuring equipment cannot be used to measure the capacity of these capacitors. Capacitance is measured per the following method: Charge capacitor for 30 minutes at rated voltage. Discharge capacitor through a constant current load. Measure voltage drop between V1 to V2.

What are the three parameters of a super capacitor?

We are going to be examining three parameters of super capacitors. Capacitance Value, Equivalent Series Resistance (ESR) and Leakage Current / Self Discharge. I will show you several ways to test each parameter and let you know what worked well for me. Why Is ESR Important?

How much farad should a capacitor be rated at?

A +-20% 500 Farad cap could actually be a 400 Farad cap even before it starts to degrade from age and use. So we know the range of acceptable values for our capacitor. In my case I have six 100 Farad capacitors rated at +-20%. This gives me an acceptable value range of 80 to 120 Farad.

What is the fastest scan rate for super capacitors?

Red is the fastest scan rate; purple is the slowest. Electrochemical Impedance Spectroscopy (EIS) is the preferred method for measuring ESR of super-capacitors. EIS also can measure capacitance and capacitor non-ideality. For basic information on EIS, see Gamry’s application note at :

Learn More

- Super Farad capacitor lead-acid battery

- Super Farad capacitor connection

- The influence of super farad capacitor on tone

- Which is the best super farad capacitor in Comoros

- Super Farad capacitor structure

- Lilongwe 15v super farad capacitor

- 27v super farad capacitor

- Super Farad Capacitor in Osaka Japan

- Rabat Super Farad Capacitor Supplier

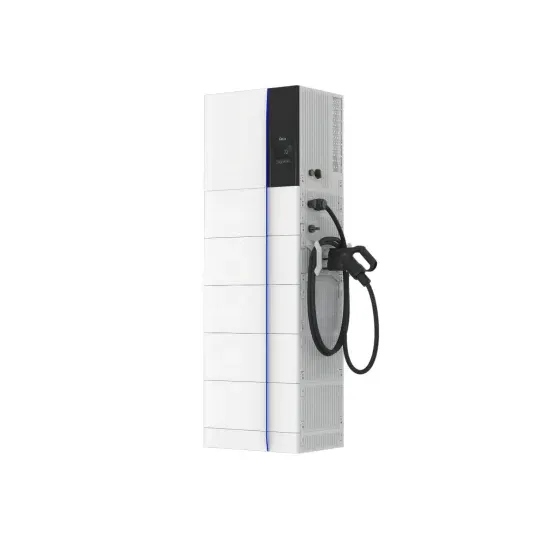

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.