5 Types Of Solar Panels Explained

Jun 24, 2024 · Monocrystalline Silicon Solar Panels Single-crystal panels, also called monocrystalline silicon panels, are one of the most mature solar energy technologies on the

Types of photovoltaic solar panels and their

Nov 6, 2017 · Monocrystalline panels are manufactured from a single crystal of pure silicon. This manufacturing process results in a very uniform material that

High-Efficiency Crystalline Photovoltaics | Photovoltaic

Apr 3, 2025 · High-Efficiency Crystalline Photovoltaics NREL is working to increase cell efficiency and reduce manufacturing costs for the highest-efficiency photovoltaic (PV) devices involving

Monocrystalline solar panels – Uses, Benefits and Drawbacks

Apr 17, 2024 · Monocrystalline solar panels offer superior efficiency and longevity compared to other types of solar panels, making them a prime choice for those seeking to invest in

Single crystal photovoltaic panel manufacturing process

Single crystal photovoltaic panel manufacturing process Due to the easier manufacturing process, these panels have a lower price point on average. In addition, polycrystalline solar panels tend

Advantages and disadvantages of single crystal and

However,the disadvantages of polycrystalline solar panels include the lower efficiency ratedue to the less pure silicon used,and their appearance,which some consider less appealing due to

Comprehensive Guide to Monocrystalline Solar

Aug 13, 2025 · Monocrystalline solar panels are photovoltaic cells composed of a single piece of silicon. These cells contain a junction box and electrical cables,

Single Crystal Photovoltaic Panel Manufacturers Supply:

As renewable energy demands skyrocket, single crystal photovoltaic panel manufacturers supply chains face unprecedented challenges. With solar installations increasing by 34% year-over

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by a protective glass and an external

Single crystal photovoltaic panel manufacturing process

In single crystalline silicon material the crystal orientation is defined by Miller indices. A particular crystal plane is noted using parenthesis such as (100). Silicon has a cubic symmetrical cubic

Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · Monocrystalline solar panels, also known as single crystalline solar panels, are made from a single continuous crystal structure. These panels are manufactured using high

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Which is better single crystal photovoltaic panel or

Oct 19, 2022 · Monocrystalline panels are made of single-crystal silicon, which is melted into bars, cut into wafers, and treated with anti-reflective coating that improves its efficiency and

Single crystal photovoltaic panel specifications and

When you evaluate solar panels for your photovoltaic (PV) system,you''ll encounter two main categories of panels: monocrystalline solar panels (mono) and polycrystalline solar panels

How Single Crystal Photovoltaic Panels Generate Electricity

The Nighttime Solar Paradox: Can Panels Work Without Sunlight? You''ve probably heard solar panels need sunlight to generate electricity. But what if I told you single crystal photovoltaic

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Single crystal solar photovoltaic panel

The utility model relates to the field of solar photovoltaic panels, and discloses a single crystal solar photovoltaic panel, which solves the problems of low photoelectric utilization rate and

Monocrystalline solar panels – Uses, Benefits

Apr 17, 2024 · Monocrystalline photovoltaic panels are a form of photovoltaic panel that is gaining popularity in the renewable energy sector. These screens

Single crystal photovoltaic panel manufacturing process

A solar module--what you have probably heard of as a solar panel--is made up of several small solar cells wired together inside a protective casing. This simplified diagram shows the type of

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

How to distinguish single crystal solar panels | NenPower

Sep 18, 2024 · To differentiate single crystal solar panels, focus on several key characteristics: 1. Appearance, 2. Price, 3. Efficiency, 4. Manufacturing process. The appear

Monocrystalline vs. Polycrystalline solar panels

Jan 9, 2023 · Key takeaways Monocrystalline solar panels have black-colored solar cells made of a single silicon crystal and usually have a higher efficiency

Single crystal photovoltaic panel and polycrystalline

Monocrystalline (mono) panels use a single silicon crystal, while polycrystalline (poly) panels use multiple crystals melted together. Here''s a breakdown of how each type of cell is made. Mono

China Single Crystal Photovoltaic Panel, Single Crystal Photovoltaic

China Single Crystal Photovoltaic Panel wholesale - Select 2025 high quality Single Crystal Photovoltaic Panel products in best price from certified Chinese manufacturers, suppliers,

PowerPoint Presentation

May 15, 2024 · Mono-crystalline Silicon The silicon used to make mono-crystalline solar cells (also called single crystal cells) is cut from one large crystal. This means that the internal

Single Crystal Solar Panels vs. Polycrystalline & Thin-Film:

When we talk about single crystal solar panels, we''re discussing the Ferraris of photovoltaic technology. These panels use silicon grown from a single crystal structure, making them the

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Understanding the Composition of Solar Panels

Apr 7, 2023 · Solar panels are composed of silicon solar cells, which convert the energy from sunlight into usable electricity. Monocrystalline cells are the most

6 FAQs about [Single crystal photovoltaic panel]

Is a monocrystalline solar panel a photovoltaic module?

Yes, a monocrystalline solar panel is a photovoltaic module. Photovoltaic (PV) modules are made from semiconducting materials that convert sunlight into electrical energy. Monocrystalline solar panels are a type of photovoltaic module that use a single crystal high purity silicon cell to harness solar power.

What is a polycrystalline solar panel?

Polycrystalline solar panels are made of numerous silicon crystals, whereas thin-film solar panels are made of photovoltaic material layers. Monocrystalline solar panels are created by developing a single crystal of silicon in a cylindrical form. This material is then cut into narrow wafers, from which solar cells are made.

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

What are the different types of monocrystalline solar panels?

There are two main variations of monocrystalline solar panels: PERC and Bifacial. PERC (Passivated Emitter and Rear Cell): PERC monocrystalline solar panels are designed to increase the efficiency of the cells by reducing energy losses from the recombination of electrons.

How are monocrystalline solar panels made?

Monocrystalline solar panels are created by developing a single crystal of silicon in a cylindrical form. This material is then cut into narrow wafers, from which solar cells are made. The wafers are then coated with an anti-reflective layer before being wired together to create a solar screen.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

Learn More

- Photovoltaic panel single crystal power generation

- Which photovoltaic panel is better single crystal or dual crystal

- What is the size of a single crystal 400w photovoltaic panel

- Commercial single crystal double glass photovoltaic panels

- Color difference of single crystal photovoltaic panels

- Use of single crystal photovoltaic panels

- Photovoltaic panel size and parameters

- Photovoltaic integrated panel manufacturer in New York USA

- How much does a photovoltaic panel cost on a roof in Turkmenistan

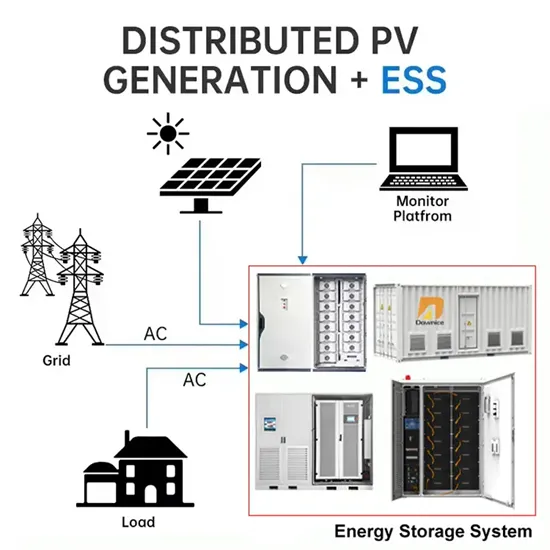

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.