Regional Growth Projections for Communication Base Station

Mar 30, 2025 · The global market for communication base station energy storage batteries is experiencing robust growth, driven by the expanding telecommunications infrastructure and

Communication Base Station Smart Hybrid PV Power

Jul 9, 2025 · Telecom Base Station Intelligent Hybrid powerSupply System (isolated type) <3.ow 18A*1 String (MPPT) z99% <6.ow 18A*2 String 120Vdc—340Vdc 420Vdc 160Vdc

Pure lead-acid batteries for telecommunication application

Mar 21, 2022 · How can the current and future challenges of mobile radio base stations be mastered from an energy storage perspective? How do the HOPPECKE HPPL battery, grid |

Long-Lasting 48V 100Ah LiFePO4 Battery Pack for Telecom,

Upgrade your Telecom base station, UPS system, or solar energy setup with the reliable CTECHI 48V 100Ah LiFePO4 Battery Pack. This high-performance battery offers extended lifespan,

Intelligent Telecom Energy Storage White Paper

Jul 7, 2023 · Execution Replacement of lead-acid batteries Basic control & Management Multiple technologies Integration New dual-network Architecture Energy internet technology and new

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and Communications Technology)

What is the purpose of batteries at telecom base

Feb 10, 2025 · Among the many types of batteries, why can lead-acid batteries become the first choice for telecom base stations? This is mainly due to its

An innovative hybrid battery management system for telecom

Oct 26, 2017 · Lead-acid battery has been widely used as a standby power for telecom industry. As the different electrical characteristic of battery among different categories, even battery

48V 100Ah LiFePO4 Battery Pack Module 5G Telecom Base Station

Base station lithium battery module has the characteristics of integration, miniaturization, light weight and intelligent centralized monitoring, and is widely used in communication base

48V Indoor Telecom Base Station with Sealed Lead Acid Battery

Aug 8, 2025 · Benefit: Embrace the transformative power of high efficiency and unparalleled reliability. Our system ensures uninterrupted connectivity and seamless communication, even

Communication Base Station Energy Storage Battery

Apr 3, 2025 · The communication base station energy storage battery market is experiencing robust growth, driven by the increasing demand for reliable and uninterrupted power supply for

Lead-Acid Batteries in Telecommunications: Powering...

Telecommunications infrastructure, including cell towers, base stations, and communication hubs, requires a constant and reliable power supply. Lead-acid batteries serve as a dependable

Telecom Battery Backup System | Sunwoda Energy

A telecom battery backup system is a comprehensive portfolio of energy storage batteries used as backup power for base stations to ensure a reliable and stable power supply. As we are

Communication Base Station Lead-Acid Battery: Powering

Why Are Lead-Acid Batteries Still Dominating Telecom Infrastructure? In an era where lithium-ion dominates headlines, communication base station lead-acid batteries still power 68% of global

Backup LiFePO4 Battery for Communication Base Station

May 6, 2025 · The capacity levels of SIKE communication backup lithium iron phosphate battery system are 50Ah, 100Ah, 150Ah, and 200Ah. The battery module adopts a modular design

Lithium Iron Phosphate Battery for Communication Base Station

The $2.7 Billion Problem: Power Backup Failures A 2023 GSMA report reveals that telecom operators lose $2.7 billion yearly due to inadequate energy storage. Lead-acid batteries – still

6 FAQs about [Power of lead-acid battery module for communication base station]

Which battery is best for telecom base station backup power?

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

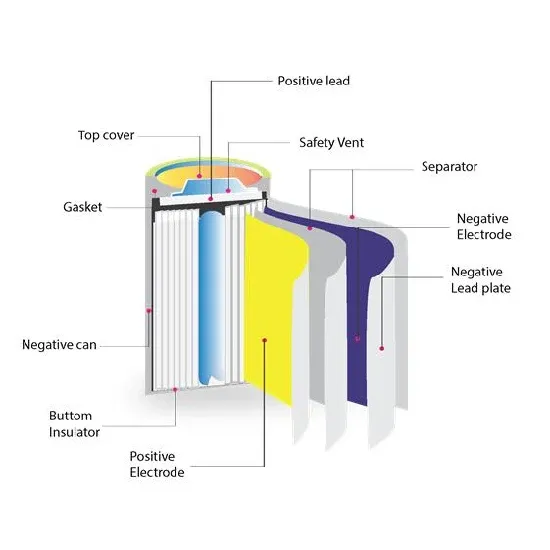

What is a lithium iron phosphate (LiFePO4) battery?

Lithium Iron Phosphate (LiFePO4) batteries are a type of lithium-ion battery with a lithium iron phosphate cathode and typically a graphite anode. Compared to traditional lead-acid batteries or other lithium-ion batteries (such as ternary lithium batteries), LiFePO4 batteries offer several notable advantages:

What makes a good battery management system?

A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging. Temperature Management: Built-in temperature sensors to monitor the battery pack’s temperature, preventing overheating or operation in extreme cold.

What is a battery management system (BMS)?

Battery Management System (BMS) The Battery Management System (BMS) is the core component of a LiFePO4 battery pack, responsible for monitoring and protecting the battery’s operational status. A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging.

How many LiFePO4 cells are in a 48V 100Ah battery pack?

1. Battery Pack Structure Design Cell Selection: A 48V 100Ah battery pack is typically composed of 15 or 16 LiFePO4 cells (each with a nominal voltage of 3.2V) connected in series. The cell capacity, such as 100Ah, can be achieved through direct parallel connection or modular design.

Learn More

- Ankara communication base station lead-acid battery photovoltaic power generation solution

- Manama communication base station lead-acid battery photovoltaic power generation system bidding

- Bhutan communication base station lead-acid battery power generation

- Gitega communication base station lead-acid battery lightning protection

- Wind power method of battery energy storage system for Naypyidaw communication base station

- Communication base station lead-acid battery UPS host

- The working power generation of the communication base station battery energy storage system includes

- San Marino integrated communication base station lead-acid battery 6 25MWh

- How much power does the battery in a communication base station have to charge

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.