Solar Powered Cellular Base Stations: Current Scenario,

Dec 17, 2015 · Cellular base stations powered by renewable energy sources such as solar power have emerged as one of the promising solutions to these issues. This article presents an

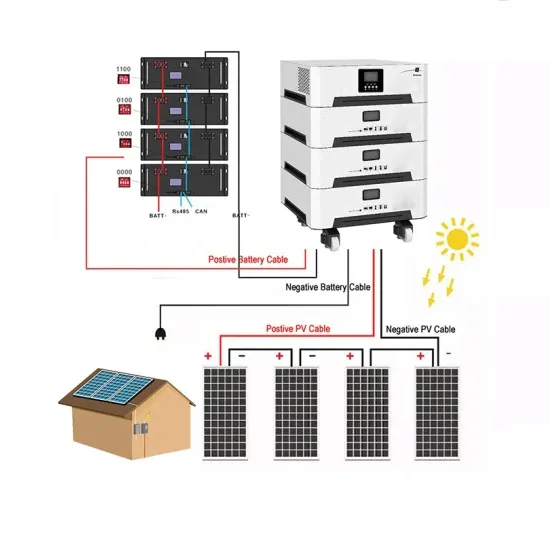

Telecommunication base station system working principle

Jan 13, 2024 · The monitoring unit can also connect to the local computer through RS485 or TCP network cable direct connection. System composition A. MPPT Photovoltaic Module: The

Multi-objective cooperative optimization of communication base station

Sep 30, 2024 · In the above model, by encouraging 5G communication base stations to engage in Demand Response (DR), the Renewable Energy Sources (RES), and 5G communication base

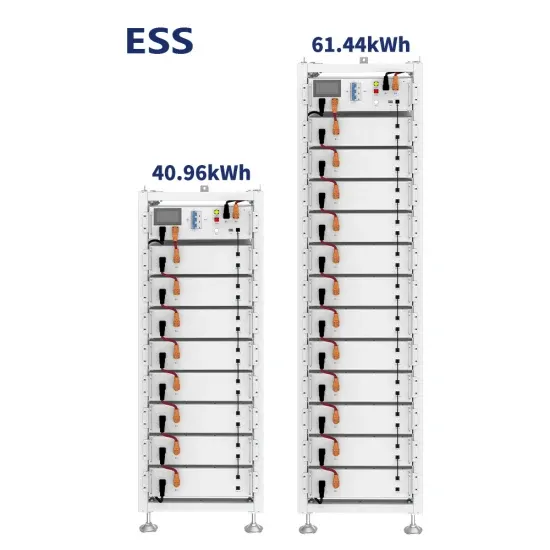

Communication Base Station Energy Storage Systems

Powering Connectivity in the 5G Era: A Silent Energy Crisis? As global 5G deployments surge to 1.3 million sites in 2023, have we underestimated the energy storage demands of modern

Experimental study on the cooling and electricity-saving

Jan 1, 2025 · The cooling requirements of communication base stations (CBSs) align with the effects of radiative cooling coatings. However, these effects have not b

Collaborative optimization of distribution network and 5G base stations

Sep 1, 2024 · In this paper, a distributed collaborative optimization approach is proposed for power distribution and communication networks with 5G base stations. Firstly, the model of 5G

How to connect solar photovoltaic base station | NenPower

May 22, 2024 · To connect a solar photovoltaic (PV) base station, specific methodologies must be applied to ensure efficiency and safety throughout the process. 1. Assess the site for optimal

Resource management in cellular base stations powered by

Jun 15, 2018 · Energy management strategies are studied in the realm of smart grids and other technologies, increasing the possibilities for energy efficiency further by employing schemes

Solar communication base station photovoltaic power

Cellular base stations powered by renewable energy sources such as solar power have emerged as one of the promising solutionsto these issues. This article presents an overview of the state

Communication Base Station Energy Solutions

With the expansion of global communication networks, especially the advancement of 4G and 5G, remote communication base stations have become increasingly critical. Many remote areas

6 FAQs about [How to connect the communication base station to electricity]

What is a communication base station?

Communication base station setups will usually include a wide array of different technologies, including power supplies, data servers, head end, radio repeaters, and communication systems that allow for high-speed continuous information flow. It can also be used as part of a leaky feeder system in the communication network.

How do I connect a base station?

Base Station Connection and Routing — Fully insert the Power Cable and Interface (I/F) Cable connectors into their respective ports in the underside of the Base Sta-tion. Then connect to an AC Adapter, and plug the AC power cord into the (wall) outlet. Figure 5. Connecting the Base Station

What are the components of a base station?

Power Supply: The power source provides the electrical energy to base station elements. It often features auxiliary power supply mechanisms that guarantee operation in case of lost or interrupted electricity, during blackouts. Baseband Processor: The baseband processor is responsible for the processing of the digital signals.

How does a mobile station communicate with a base station?

The communications between mobile station and base station occur concurrently via two air interface channels from each base station separately. Both channels (signals) are received at the mobile station by maximal combining Rake processing (see Figure 11.20 ). Soft handoff occurs in about 20–40% of calls. Figure 11.20. Soft handoff in CDMA.

How to set up the base station and transmitter?

To set up the base station and transmitter, first insert 2XAA 1,5V alkaline rechargeable batteries into the battery compartment of the remote sensor. Then, insert 3XAA 1,5V alkaline batteries into the base station, observing the correct polarity.

How does a base station work?

It usually connects the device to other networks or devices through a dedicated high bandwidth wire of fiber optic connection. Base stations typically have a transceiver, capable of sending and receiving wireless signals; Otherwise if they only send the trailer it will be considered a transmitter or broadcast point only.

Learn More

- How to connect the power supply battery of the communication base station

- How does the communication base station get electricity

- How to connect to the communication base station and wind and solar hybrid

- How to set up wind power generation at communication base station

- Does a communication base station consume electricity in a year

- How to use the communication photovoltaic mini base station

- How much does a wind-solar hybrid energy storage cabinet for a communication base station cost

- Communication base station solar energy 5kWh electricity wholesale

- How to connect the leads of the base station power cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.