MgZnO High Voltage Thin Film Transistors on Glass for

Dec 4, 2023 · We demonstrate a Magnesium Zinc Oxide (MZO) based high voltage thin film transistor (HVTFT) built on a transparent glass substrate. The devices are designed with

Review of state-of-the-art: Inverter-to-array power ratio for thin

Jul 1, 2017 · In this paper, the state-of-the-art is presented to collect a relevant information related to the sizing ratio around the globe as well as introduces a new concept of inverter sizing

PHOTOVOLTAIC MODULES AND INVERTERS

Mar 5, 2025 · The different inverter types available in the market are central inverters, string inverters, micro inverters, smart inverters and battery-based inverters. Central inverters are

Solar technology guide: Panels to cells

May 5, 2025 · Standard solar panels contain photovoltaic (PV) cells on only the side that faces the sun. Bifacial solar panels, on the other hand, have PV cells on both the front and back,

SigenMicro Inverter | Solar Micro Inverter for Residential Use

SigenMicro, the world''s first MLPE solution to integrate Mesh technology, boosts signal coverage and stability. Its innovative "EMS inside" design eliminates the need for a Network gateway''s

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition

Review of degradation and failure phenomena in photovoltaic

May 1, 2022 · The degradation of photovoltaic (PV) systems is one of the key factors to address in order to reduce the cost of the electricity produced by increasing the operational lifetime of PV

A multi-string photovoltaic inverter for thin-film or back-side

Apr 21, 2016 · Photovoltaic inverters are widely used to feed solar generated power into the public grid. Inverter topologies have to be carefully chosen, depending on the typ

Photovoltaics: Basic Principles and Components

Oct 14, 2013 · Photovoltaics: Basic Design Principles and Components If you are thinking of generating your own electricity, you should consider a photovoltaic (PV) system—a way to gen

Review of state-of-the-art: Inverter-to-array power ratio for thin

Jul 1, 2017 · Numerous sizing methodology for the combination of inverter and PV array components have appeared in the literature including guidelines and third-party field studies.

Control and Design of an Inverter for Grid Connected

Mar 7, 2022 · I. INTRODUCTION The „direct current‟ to „alternating current‟ (DC-AC) inverter concepts for photovoltaic (PV) applications. The PV module is capable of generating electric

Solar Panel vs Solar Inverter: Let''s Break It Down!

May 2, 2024 · When it comes to solar energy, think of panels as sun collectors and inverters as power translators. Panels convert sunlight into electricity,

Photovoltaic micro-inverter with active filtering and thin-film

Nov 22, 2017 · This work proposes the application of an active filtering method to compensate the dc-link low frequency voltage ripple of a 250 W two-stage PV micro-inverter.

Chapter 1: Introduction to Solar Photovoltaics – Solar

Chapter 1: Introduction to Solar Photovoltaics 1.1 Overview of Photovoltaic Technology Photovoltaic technology, often abbreviated as PV, represents a revolutionary method of

Design and Sizing of Solar Photovoltaic Systems

Mar 15, 2023 · However, although thin film materials have higher light absorption than equivalent crystalline materials, thin film PV cells suffer from poor cell conversion efficiency due to their

2022 product catalogue-A

Jan 9, 2025 · As of September 30, 2021, JinkoSolar has delivered more than 80GW solar panels globally,which makes JinkoSolar the world''s largest photovoltaic module manufacturer in terms

Hybrid Solar System: How It Works and Its Benefits

Jun 27, 2024 · Thin Film Solar Panel Like other solar panels, thin-film panels convert light energy into electrical energy via the photovoltaic effect. Unlike

Changes and challenges of photovoltaic inverter with silicon carbide

Oct 1, 2017 · 1. Introduction With the continuous decrease in the cost of photovoltaic (PV) modules and inverters, solar energy has become a competitive source of renewable energy

What is a photovoltaic inverter?Selection, Principles & Future

Apr 28, 2025 · Gain a deep understanding of the working principles, key classifications, and crucial roles of photovoltaic inverters in solar power generation systems. This article

Design and Implementation of a Micro-Inverter for

Mar 21, 2020 · Date: .. ABSTRACT The objective of this work is to design and build a novel topology of a micro-inverter to directly convert DC power from a

How PV Cells Harness the Sun to Generate

Jun 2, 2024 · Inverters: Photovoltaic cells generate direct current (DC) electricity, but most household appliances and the electrical grid operate on alternating

Advancements In Photovoltaic (Pv) Technology for Solar

Jul 13, 2023 · Abstract: Photovoltaic (PV) technology has witnessed remarkable advancements, revolutionizing solar energy generation. This article provides a comprehensive overview of the

Thin Film Photovoltaics

Jan 1, 2018 · Thin film solar cell technology has recently seen some radical advancement as a result of new materials and innovations in device structures. The increase in the efficiency of

Design and Sizing of Solar Photovoltaic Systems

Feb 2, 2022 · DESIGN AND SIZING OF SOLAR PHOTOVOTAIC SYSTEMS Photovoltaic (PV) systems (or PV systems) convert sunlight into electricity using semiconductor materials. A

6 FAQs about [Thin and light photovoltaic inverter]

What are the different types of PV inverters?

There are various sizes and power classes. They are available with and without frames, as flexible or inflexible versions, manufactured using the crystalline or thin-film procedures and also made of various materials. Likewise, there are various models of PV inverters, employing different topologies and concepts.

Is there a right combination of PV module and inverter?

What seems like a double dilemma at first, is actually the solution. There is in fact a right inverter for every available module technology. Yet, it is not always easy to find the right combination of PV module and inverter. The modules simply have too many different characteristics. There are various sizes and power classes.

What is the difference between transformerless and galvanically isolated inverters?

In terms of module compatibility, the distinction between transformerless and galvanically isolated inverters is probably the most important one. Thanks to their galvanic isolation, devices with a transformer allow grounding the PV array, a requirement for some module types.

Which Inverter should I use?

In order to avoid unwanted deactivation, it is recommended to use an inverter that has no notable fluctuations of potential on the DC side (transformer device or transformerless inverter with quiet rail topology). The inverters available allow realizing any conceivable plant configurations.

Why are transformerless inverters not a viable option?

Thin-film silicon (a-Si): Cells based on amorphous silicon have a tendency towards corrosion of the TCO, which leads to a permanent loss of output (problem no. 1). The solution is to negatively connect the generator to ground, which is why most transformerless inverters are not a viable option.

What happens if a microinverter loses a signal?

Every microinverter participates in a competition: the one with the best signal becomes the master, others slaves. If the master loses signal, a slave seamlessly takes over, ensuring system stability. Sigenergy AI recognition algorithm automatically identifies the layout of rooftop PV modules from drawings.

Learn More

- Photovoltaic power supply light storage inverter

- Is the photovoltaic inverter quick to install

- Photovoltaic inverter photovoltaic combiner box

- Household 5 kW photovoltaic inverter

- Photovoltaic inverter pcb

- Energy storage inverter for photovoltaic power source

- How to choose the inverter power for photovoltaic projects

- Photovoltaic inverter trading

- Inverter photovoltaic profit share

Industrial & Commercial Energy Storage Market Growth

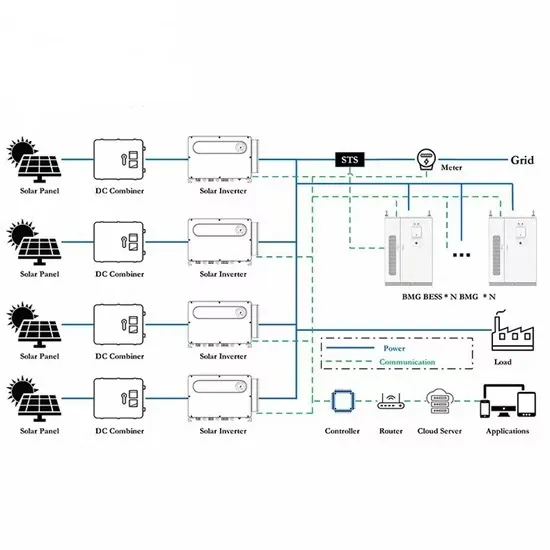

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.