Battery and energy management system for vanadium redox flow battery

Feb 1, 2023 · As one of the most promising large-scale energy storage technologies, vanadium redox flow battery (VRFB) has been installed globally and integrated with microgrids (MGs),

Vanadium redox flow batteries: Flow field design and flow

Jan 1, 2022 · The process of flow field design and flow rate optimization is analyzed, and the battery attributes and metrics for evaluating VRFB performance are summarized. The focus of

Redox flow battery:Flow field design based on bionic

Oct 15, 2024 · Flow field design (a-d) inspiration ideas, (e-g) adding obstruction in the main channel, (h) battery structure diagram, (i) battery testing system, (j) electrochemical reaction

Technology: Flow Battery

Nov 4, 2024 · A flow battery is an electrochemical battery, which uses liquid electrolytes stored in two tanks as its active energy storage component. For charging and discharging, these are

Mechanical Design of Flow Batteries

Jan 13, 2022 · Researchers are searching for next-generation battery materials, and this thesis presents a systems analysis encompassing static and moving electrode architectures that

Design and development of large-scale vanadium redox flow batteries

Jan 30, 2024 · Vanadium redox flow battery (VRFB) energy storage systems have the advantages of flexible location, ensured safety, long durability, independent power and capacity

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

Membraneless-architectured redox flow batteries

Larger-scale demonstrations involve electrodeposited anodes and hybrid flow batteries, defined here as systems combining liquid electrolytes with solid- or gas-phase electrode reactions.

Design and Performance of Organic Flow Batteries

Aug 12, 2023 · Membrane is another prominent material in the structural design of flow batteries as it significantly influences the cycling performance of the battery system. The membrane is

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for

A novel hybrid battery thermal management system using TPMS structure

Jan 15, 2025 · Based on the temperature clouds in Fig. 8, it can be seen that under the same flow rate, the system with a thermal buffer layer structure of PCM/TPMS exhibits lower battery

Electrochemistry Encyclopedia Flow batteries

Apr 28, 2023 · Typical structural configuration of a redox flow battery. Two important components of flow batteries are their positive and negative electrodes, which are separated by a

Recent advancements in membrane-free redox flow batteries

Feb 15, 2025 · Abstract Membrane-free redox flow batteries (RFBs) are promising energy-storage technologies that present an innovative solution to address the critical need for sustainable

Review on modeling and control of megawatt liquid flow

Jun 1, 2023 · Flow battery has recently drawn great attention due to its unique characteristics, such as safety, long life cycle, independent energy capacity and power output. It is especially

Redox flow batteries and their stack-scale flow fields

Nov 1, 2023 · The review then investigates the pattern design and structure optimization of serpentine- and interdigitated-based flow fields before discussing challenges and strategies for

Advances in flow pattern design of liquid-cooled components for battery

Feb 1, 2025 · The liquid-cooled component is a key part of liquid-cooled thermal management system, which controls the temperature of batteries to ensure safety and high performance of

SECTION 5: FLOW BATTERIES

Jun 14, 2022 · Flow batteries are electrochemical cells, in which the reacting substances are stored in electrolyte solutions . external to the battery cell. Electrolytes are pumped. through

Rechargeable redox flow batteries: Flow fields, stacks

advanced flow batteries and largeBscale flow battery stacks. Xinyou Ke is currently a Ph.D. candidate in the Department of Mechanical and Aerospace Engineering at Case Western

Environmental performance of integrated solar flow battery systems

Apr 15, 2023 · Integrated solar flow batteries (SFBs) are developed from a novel technology combining the functions of electricity generation and storage in one inte

Flow battery system structure

The flow battery system structure comprises at least one pile, a positive electrolyte storage tank, a negative electrolyte storage tank and a power supply and/or power utilization device, wherein

A low-cost all-iron hybrid redox flow batteries enabled by

Jul 1, 2024 · This indicates that the deep eutectic solvents successfully altered the coordination structure of Fe2+, although the performance of the all-iron RFBs reported in the literature still

Flow field structure design for redox flow battery:

Aug 1, 2024 · In this review, the flow and distribution characteristics of traditional flow fields are presented. The effects of traditional flow fields on distribution uniformities in single battery and

Numerical analysis of asymmetric biomimetic flow field structure

Feb 1, 2025 · In redox flow battery systems, the design of the flow field structure significantly influences reactions, mass transfer, and electrolyte distribution within the battery. The

6 FAQs about [Flow battery system structure]

What are the components of a flow battery?

Flow batteries comprise two components: Electrochemical cell Conversion between chemical and electrical energy External electrolyte storage tanks Energy storage Source: EPRI K. Webb ESE 471 5 Flow Battery Electrochemical Cell Electrochemical cell Two half-cellsseparated by a proton-exchange membrane(PEM)

How do flow batteries work?

Charging and discharging are realized by means of a reversible electrochemical reaction between two liquid electrolyte reservoirs. Flow batteries are often called redox flow batteries, based on the redox (reduction–oxidation) reaction between the two electrolytes in the system. Fig. 9. Flow battery system .

What is a true flow battery?

True flow batteries have all the reactants and products of the electro-active chemicals stored external to the power conversion device. Systems in which all the electro-active materials are dissolved in a liquid electrolyte are called redox (for reduction/oxidation) flow batteries.

How does a flow battery differ from a conventional battery?

In contrast with conventional batteries, flow batteries store energy in the electrolyte solutions. Therefore, the power and energy ratings are independent, the storage capacity being determined by the quantity of electrolyte used and the power rating determined by the active area of the cell stack.

Where do flow batteries store electricity?

The flow batteries store electricity in the tanks of liquid electrolyte that is pumped through electrodes to extract the electrons. The flow batteries store electricity in the tanks of liquid electrolyte that is pumped through electrodes to extract the electrons.

What are the characteristics of a flow battery?

A typical flow battery has been shown in Fig. 8. Some of the main characteristics of flow batteries are high power, long duration, and power rating and the energy rating are decoupled; electrolytes can be replaced easily . Fig. 8. Illustration of flow battery system [133,137]. 2013, Renewable and Sustainable Energy Reviews Zhibin Zhou, ...

Learn More

- Communication base station flow battery detector

- Iron-based liquid flow battery energy storage system

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Africa s new all-vanadium liquid flow battery

- 1gw all-vanadium liquid flow battery energy storage

- Nigeria s new all-vanadium flow battery

- Nigerian Vanadium Flow Battery

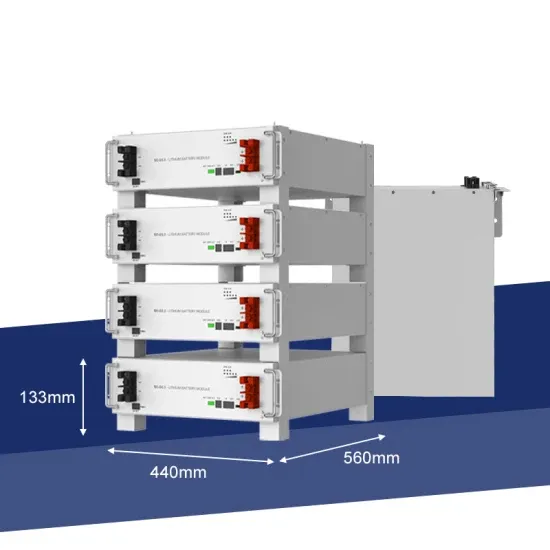

- Large energy storage battery cabinet structure

Industrial & Commercial Energy Storage Market Growth

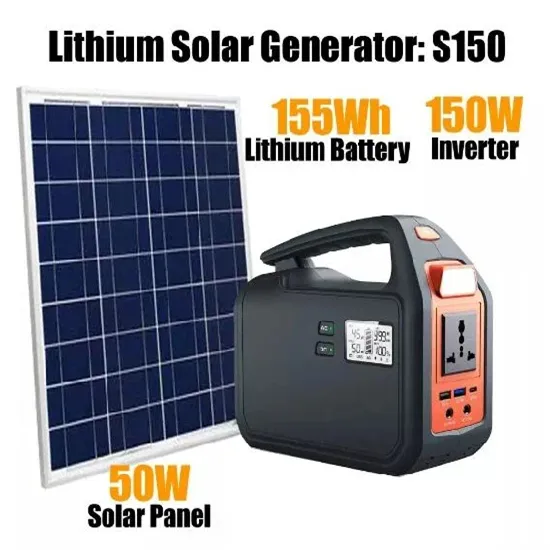

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.