There are several ways to dissipate heat in energy storage battery cabinets

Advances in battery thermal management: Current landscape Liquid cooling provides better heat dissipation and more precise temperature control compared to air cooling by using a

Does the battery charging cabinet dissipate heat How to

The safety of battery charging cabinets depends on several factors, including the quality of the cabinet, compliance with safety standards and regulations, and proper use and maintenance.

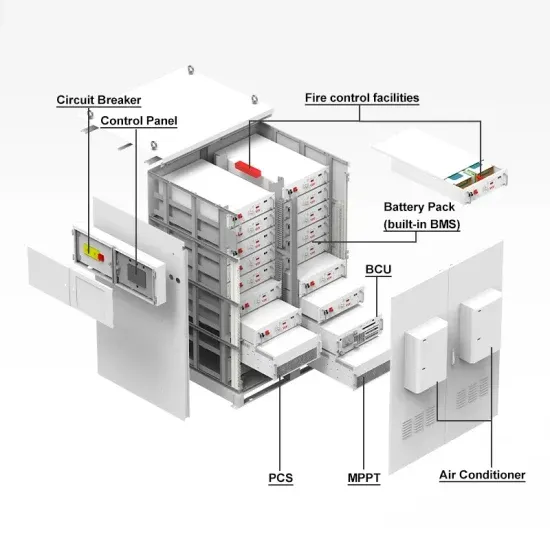

How to design an energy storage cabinet: integration and

Jan 3, 2025 · As the core equipment in the energy storage system, the energy storage cabinet plays a key role in storing, dispatching and releasing electrical energy. How to design an

How does the new energy battery cabinet dissipate heat

Battery thermal management is becoming more and more important with the rapid development of new energy vehicles. This paper presents a novel cooling structure for cylindrical power

Liquid Cooling: Efficiency in Battery Storage

The Evolution of Energy Storage Cooling As the world transitions towards renewable energy sources, the demand for efficient and reliable Commercial & Industrial (C&I) energy storage

How does the energy storage cabinet dissipate heat

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Heat-dissipation basics for EV batteries

Rittal: How to dissipate heat from control cabinet One of the most common ways to dissipate heat from control cabinet enclosures is through forced air cooling. This method uses a fan or blower

Study on performance effects for battery energy storage

Feb 1, 2025 · By increasing air supply volume, cooling effect of cooling system can be improved. Design A has lower temperature standard deviation than other three designs. Effect of

How does the energy storage battery cabinet dissipate heat

Energy Storage Systems (ESS) and Solar Safety Thermal runaway is a term used for the rapid uncontrolled release of heat energy from a battery cell; it is a condition when a battery creates

How to dissipate heat quickly in energy storage charging

Community resiliency is essential in both rural and urban settings. Energy storage can help meet peak energy demands in densely populated cities, reducing strain on the grid and minimizing

NYS implements fire safety as battery storage investments

Jul 21, 2025 · Safety considerations are growing as New York state invests in different renewable energies after a battery storage system in Ulster County caught fire but was quickly

Two different ways to dissipate heat in a battery pack

The temperature environment in the battery pack has a huge impact on the reliability, life and performance of the battery cell. Therefore, choosing a suitable heat dissipation method to

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · Heat dissipation from Li-ion batteries is a potential safety issue for large-scale energy storage applications. Maintaining low and uniform temperature distribution, and low

The role of heat dissipation materials in battery cabinets

Battery heat builds up quickly,dissipates slowly,and rises swiftly in the early stages of discharge,when the temperature is close to that of the surrounding air. Once the battery has

Study on performance effects for battery energy storage

Feb 1, 2025 · The purpose of this study is to develop appropriate battery thermal management system to keep the battery at the optimal temperature, which is very important for electrical

How does the battery cabinet dissipate heat

How does the energy storage battery cabinet dissipate heat . Thermal runaway is a term used for the rapid uncontrolled release of heat energy from a battery cell; it is a condition when a

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Thermal management systems in battery energy storage cabinets are vital for regulating the internal temperature of the batteries. As batteries discharge and charge, they

Research on Heat Dissipation of Cabinet of Electrochemical Energy

Apr 1, 2025 · During the operation of the energy storage system, the lithium-ion battery continues to charge and discharge, and its internal electrochemical reaction will inevitably generate a lot

How to correctly install lithium battery energy

Mar 25, 2024 · Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services

What are the ways to dissipate heat for energy storage batteries

Apr 11, 2024 · To effectively dissipate heat for energy storage batteries, several methodologies exist, including 1. Utilizing advanced thermal management systems, 2. Implementing phase

Energy Storage Cabinets: Unveil the Breakthroughs

May 2, 2025 · 2.1 Innovative Cooling Technologies During the charging and discharging processes, energy storage cabinets generate heat. If not properly managed, this heat can lead

5 FAQs about [How to quickly dissipate heat in energy storage battery cabinets]

How to heat dissipate heat from a battery?

The connection between the heat pipe and the battery wall pays an important role in heat dissipation. Inserting the heat pipe in to an aluminum fin appears to be suitable for reducing the rise in temperature and maintaining a uniform temperature distribution on the surface of the battery.

How to isolate battery cells to protect against heat propagation?

The primary strategies to isolate battery cells to protect against heat propagation all have pluses and minuses. Designing a battery module or pack requires balancing several competing thermal factors. The most common strategy is to provide just-enough thermal management to achieve the battery pack’s fundamental goals.

How to prevent thermal propagation in cell battery packs?

Spreading is the best way to prevent thermal propagation in pouch and prismatic cell battery packs because it prevents propagation while extending cell cycle lifetime and fast charging while cutting size and weight. Flexible graphite heat spreaders outperform aluminum and can support high-performance, small, lightweight battery packs.

How do you design a battery pack?

Designing a battery module or pack requires balancing several competing thermal factors. The most common strategy is to provide just-enough thermal management to achieve the battery pack’s fundamental goals. Adding additional thermal management material only adds cost, weight, and volume.

Is graphite a good battery pack?

For higher-performance battery packs, the amount of aluminum needed for safe, efficient operation may result in a pack that is too heavy and bulky. Aluminum is dense and has poor thermal conductivity (200W/mK), but graphite is lightweight and has high thermal conductivity (400W/mK to 1,100W/mK).

Learn More

- How to choose the heat dissipation of the battery energy storage system of the communication base station

- How much does it cost to transport lithium battery energy storage cabinets by air

- How much does it cost to replace the energy storage lithium battery

- How to generate electricity from a base station using photovoltaic energy storage cabinets

- How big is a 5Kw solar energy storage battery

- How much does the London energy storage battery cost

- How to calculate the battery capacity of the energy storage cabinet

- How much is the voltage of the energy storage battery cabinet

- How much does a battery energy storage system cost in Egypt

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.