Energy storage container equipment layout

How do I design a battery energy storage system (BESS) container? and adherence to industry best practices. Here''s a step-by-step gui e to help you design a BESS container: 1. Define the

10-Foot Energy Storage Container: The Complete Guide to

A standard 10-foot energy storage container typically measures 2991mm (L) × 2438mm (W) × 2591mm (H). But here''s the kicker - these dimensions aren''t just random numbers.

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · Discover the essential steps in designing a containerized Battery Energy Storage System (BESS), from selecting the right battery technology and system architecture to

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Design Specifications for Containerized Energy Storage

In consequence, as the energy storage power source of the power system, the containerized energy storage system is the development direction of energy storage in the future. the

Energy Storage Battery Container Layout: Design Secrets for

Mar 19, 2025 · Ever tried fitting a week''s worth of camping gear into a hatchback? That''s essentially what engineers face when designing energy storage battery container layouts. With

Detailed Understanding of the Containerized Battery System

Dec 13, 2024 · The containerized battery system has become a key component of contemporary energy storage solutions as the need for renewable energy sources increases. This system is

Layout of containerized energy storage power station

Let''s dive in! What are containerized BESS? Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are

Energy storage container layout design

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Energy storage battery system container design

Simply put, container battery storage refers to a mobile, modular energy storage system housed within a standard shipping container. utility-scale battery storage system with a typical storage

Numerical simulation of encapsulated mobilized-thermal energy storage

Aug 15, 2024 · With the ongoing development and widespread adoption of renewable energy sources, energy storage technologies have gained increasing significance. In recent years, the

Full-scale walk-in containerized lithium-ion battery energy storage

Dec 1, 2022 · Three installation-level lithium-ion battery (LIB) energy storage system (ESS) tests were conducted to the specifications of the UL 9540A standard test method [1]. Each test

Requirements for energy storage container layout

battery energy storage system (BESS) container design seq and development of a containerized energy storage system. This system is typically used for large-scale energy storage

Inside AC Block Architecture: A Technical Walkthrough of

Nov 15, 2024 · The rapid deployment of utility-scale battery energy storage systems (BESS) demands a comprehensive understanding of system architecture, electrical engineering

What Is The Battery Compartment in The Energy

Mar 6, 2025 · Container type energy storage is generally DC side energy storage, with batteries installed inside the box and a small number of PCS installed.

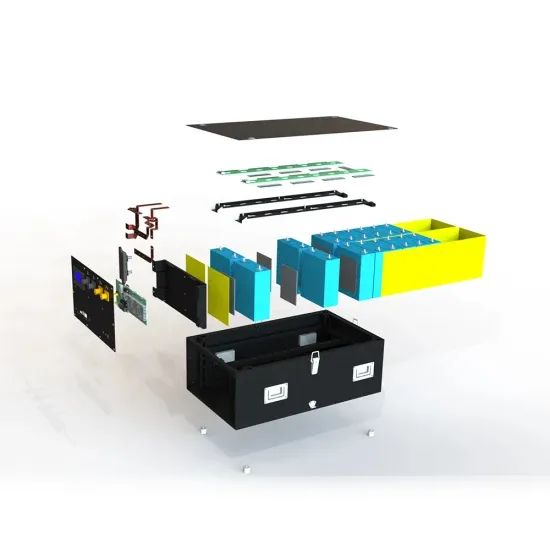

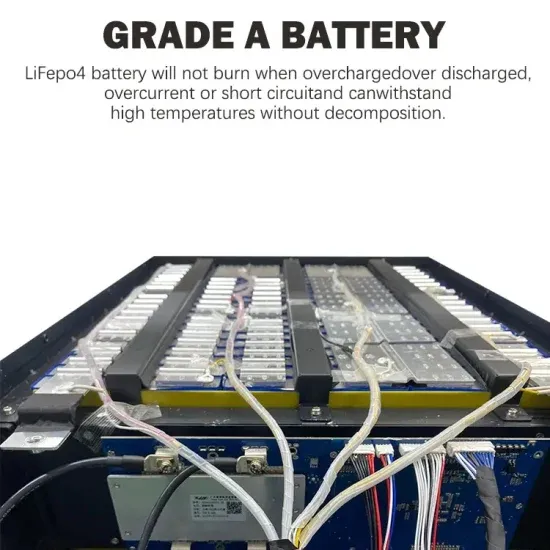

Battery Enclosure: Carrying Platform and Safety for Energy Storage

Aug 1, 2025 · In the construction of an energy storage system (ESS), the cells, the battery management system (BMS), the safety design and the electrical topology are undoubtedly the

6 FAQs about [Layout inside the energy storage container]

What is a battery energy storage system (BESS) container design sequence?

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system. This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power.

What are the challenges in designing a battery energy storage system container?

The key challenges in designing the battery energy storage system container included: Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment.

What is an energy storage system?

This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power. Here's an overview of the design sequence:

How do I integrate an efficient HVAC system into the container design?

We integrated an efficient HVAC system into the container design by: Incorporating two AC chillers to cool the battery area, regulating the temperature inside the container. Installing two mounted fans on top of the transformer block to circulate the air and ensure efficient heat dissipation.

How to optimize battery storage system performance and safety?

To ensure optimal performance and safety of battery storage system, effective thermal management was a key consideration in the design. We integrated an efficient HVAC system into the container design by: Incorporating two AC chillers to cool the battery area, regulating the temperature inside the container.

What are the requirements & specifications for a Bess container?

1. Requirements and specifications: - Determine the specific use case for the BESS container. - Define the desired energy capacity (in kWh) and power output (in kW) based on the application. - Establish the required operational temperature range, efficiency, and system lifespan.

Learn More

- Inside the container energy storage

- Monitoring equipment inside the energy storage container

- Price of temperature control system for energy storage container

- Energy storage container air duct structure

- Georgetown container energy storage project bidding

- Energy storage container assembly line base station power generation

- Slovakia Customized Container Energy Storage Manufacturer

- Container battery energy storage manufacturers ranking

- St George energy storage explosion-proof container wholesale

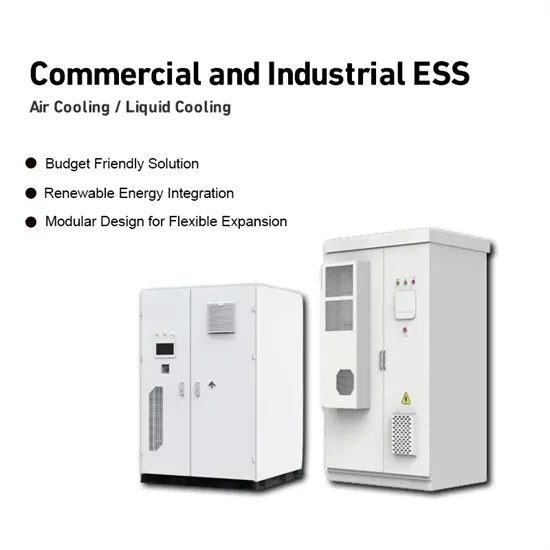

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.