A Computationally Efficient Thermal Model of Cylindrical

Mar 9, 2016 · Abstract—This paper presents a computationally efficient thermal model of a cylindrical lithium ion battery for real-time applications. Such a model can be used for thermal

Batteries & Fuel Cells Module Model Library

Dec 11, 2013 · Thermal Modeling of a Cylindrical Li-ion Battery in 3D Introduction This model example simulates an air-cooled cylindrical 18650 lithium-ion battery in 3D.

Battery Design Module Application Gallery Examples

This model example simulates an air-cooled cylindrical 18650 lithium-ion battery during a charge-discharge cycle, followed by a relaxing period. A lumped (0D) cell model is used to model the

A comprehensive numerical study on electrochemical-thermal models

May 1, 2022 · Modelling the electrochemical and thermal behaviours of cylindrical lithium-ion batteries (LIBs) is complicated by their multi-unit jellyroll structure. To evaluate the accuracy of

Thermal Modeling of a Cylindrical Lithium-ion Battery in

Apr 15, 2015 · Introduction This example simulates an air-cooled cylindrical 18650 lithium-ion battery in 3D. The model follows the same approach as the Application Libraries example

COMSOL Multiphysics Application Library

Sep 28, 2020 · Introduction This model is used within the Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D and Liquid-Cooled Lithium-Ion Battery Pack examples to create an

Thermal modelling of cylindrical Lithium-Ion batteries to

With inputs and average characteristics such as open-circuit voltage (OCV), state of charge (SOC), thermal conductivities, specific heat capacities, and density of the materials employed,

A Computationally Efficient Coupled Electrochemical-Thermal Model

Sep 11, 2019 · We present a one-dimensional, radial, coupled degradation-electrochemical-thermal (DET) model of a large format cylindrical lithium ion cell. The model consists of

Investigating thermal dynamics in cylindrical Li-ion batteries

5 days ago · This study presented an electrochemical-thermal model for cylindrical lithium-ion batteries, integrating a detailed multi-layer thermal framework with electrochemical dynamics.

Modified Pseudo-Two-Dimensional Model for Spiral-Wound Cylindrical

This study investigates the sufficiency of P2D-lumped model for cylindrical LIBs for tabbed and tab-less design: first, via a scale analysis and then, by comparing its predictions with detailed

Analysis of Cylindrical Lithium Battery Advantages and Common Models

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · This research proposes a novel experimental methodology and a theoretical model for evaluating the mechanical performance of cylindrical lithium-ion batteries under

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery

A Computationally Efficient Thermal Model of Cylindrical

Mar 9, 2016 · In this paper, we propose a computationally efficient thermal model for a cylindrical battery cell and its application for estimating core and surface temperatures. Toward this end,

Parameterization and heat generation investigation of cylindrical

Dec 15, 2024 · To comprehensively investigate the electrochemical and thermal behaviors of cylindrical lithium-ion batteries (LIBs), an appropriate reconstructed electrochemical-thermal

Thermo-electric behavior analysis and coupled model

Nov 1, 2024 · In this article, a characterization approach for the coupled battery thermo-electric model affected by cyclic aging is designed by taking the 21,700 cylindrical ternary lithium

Lithium Battery Cell Types and Model Numbers in Different

Five-digit numbers usually represent cylindrical lithium-ion cells. From the left side, the first and second digits refer to the diameter of the battery, the third and fourth digits refer to the height

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

1D Lithium-Ion Battery for Thermal Models

Sep 23, 2022 · Introduction This model is used within the Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D and Liquid-Cooled Lithium-Ion Battery Pack examples to create an

A Comparative Study of Control-Oriented Thermal Models for Cylindrical

Nov 14, 2019 · This article, for the first time, presents a comprehensively comparative study of seven representative control-oriented thermal models for cylindrical Li-ion batteries. These

Lithium battery model table, Lithium battery specification and model

Nov 9, 2020 · Cylindrical lithium battery model specificationsThe model name of cylindrical lithium battery consists of three letters and five digits. IEC61960 stipulates the rules for cylindrical and

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Apr 28, 2025 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

1D Lithium-Ion Battery for Thermal Models

This model is used within the Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D and Liquid-Cooled Lithium-Ion Battery Pack examples to create an average heat source in an

A universal anisotropic model for a lithium‐ion cylindrical cell

Mar 13, 2022 · Finite element models were developed for lithium-ion batteries. Two jellyroll materials were calibrated and compared, one isotropic and one anisotropic crushable foam

6 FAQs about [Cylindrical lithium battery models]

How to model a cylindrical lithium ion battery in 3D?

Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D This example simulates the heat profile in an air-cooled cylindrical battery in 3d. The battery is placed in a matrix in a battery pack. The thermal model is coupled to a 1d-battery model that is used to generate a heat source in the active battery material.

How do you model a cylindrical lithium-ion battery?

For the modeling of cylindrical lithium-ion batteries, detailed structural models including cathode material, cathode material, diaphragms, and shells can more accurately react to battery deformation and faults, and determine the failure position, but usually require significant computational costs and the model is particularly complex.

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

Is there a homogenization model for lithium ion batteries?

At present, there have been many breakthroughs in the research of homogenization models. Xia et al. and Wang et al. respectively established a homogenization model of the cylindrical lithium-ion battery, considering the material as anisotropy and the influence of SOC and dynamic effect.

Does the 18650 cylindrical lithium-ion battery have a quasi-static compression test?

4. Conclusion In this paper, the 18650 cylindrical lithium-ion battery and its jellyroll quasi-static compression test, and establishes an optimization model based on the experimental results.

How to model the internal geometry of cylindrical cells in thermal models?

There are two main approaches in modelling the internal geometry of cylindrical cells in thermal models: (1) homogeneous and (2) discrete. For a simplified homogeneous thermal model, its thermal conductivity and heat capacity in the radial and normal directions are calculated separately.

Learn More

- Ecuador nca cylindrical lithium battery

- What kind of cylindrical lithium battery is it

- Venezuelan cylindrical lithium battery milliwatt normal

- Dili Large Cylindrical Lithium Battery

- How many volts is the largest cylindrical lithium battery in Albania

- Capacity cylindrical lithium battery

- Tunisian cylindrical lithium battery

- Is the Wellington cylindrical lithium battery useful

- Madrid cylindrical lithium battery

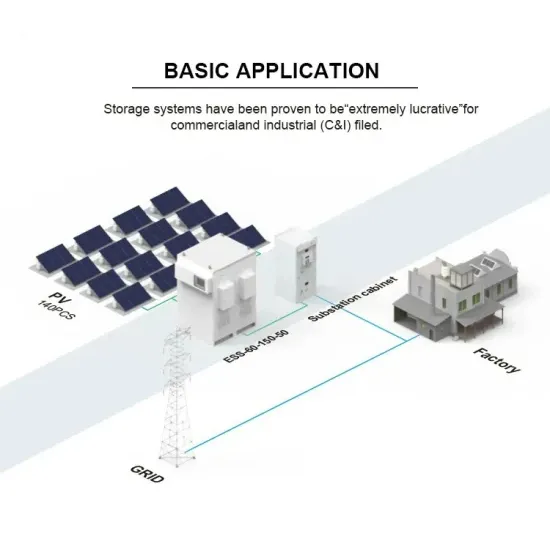

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.