Reconstruction of Battery System Temperature Field Based

Nov 11, 2024 · Lithium-ion batteries are extensively utilized across various fields, but their thermal fragility has been seriously concerned. Lithium-ion batteries are easily affected by working

How to Build a High-Powered 60V Lithium-Ion Battery Pack

Aug 11, 2025 · How to Build a High-Powered 60V Lithium-Ion Battery Pack Are you looking to create a powerful 60V lithium-ion battery pack for your DIY project? Building your own battery

What to Know About a 60V Lithium Battery Pack

Jul 22, 2024 · A 60V lithium battery pack offers significant advantages, including high energy density, lightweight design, and long lifespan, making it ideal for various applications such as

Understanding 60V Lithium Batteries: Types, Prices, and

Feb 18, 2025 · Lithium batteries are becoming increasingly popular due to their efficiency and long lifespan. Among them, 60V lithium batteries are especially notable for their application in

Three-dimensional Temperature Field Reconstruction for A Lithium

Aug 10, 2017 · To address this threat, this paper, for the first time, seeks to reconstruct the three-dimensional temperature field of a LiB pack in real time. The major challenge lies in how to

Understanding the 60V Lithium Battery: Voltage, Capacity,

Feb 18, 2025 · Lithium batteries have become increasingly popular in recent years, particularly in applications such as electric vehicles, renewable energy storage, and various portable

锂离子电池PACK知识全面讲解

电动两轮车锂电池PACK基本结构 两轮车锂电池PACK的主要硬件部件包括:防火外壳、LED显示屏(仅用于电池包部分)、智能BMS、电芯、电芯座、密封

Reconstruction of lithium replenishment channel with an

The regenerated LCO (RLCO) exhibits an outstanding discharge capacity of 179.10 mAh·g<sup>−1</sup> in the voltage range of 3.0–4.5 V at 0.5 C. The proposed strategy is an

Electrochemistry‐Driven Complete Reconstruction of Spent

Apr 4, 2025 · The rapid expansion of lithium‐ion batteries (LIBs) applications has created urgent recycling challenges. To tackle these issues, we propose a novel electrochemistry‐driven

How Can You Understand and Utilize a 60V 20AH Battery Pack?

Jul 19, 2024 · How Does a 60V 20AH Battery Pack Work? A 60V battery pack operates by utilizing lithium-ion technology, which allows for high energy density and efficient power delivery.

Batteries | Free Full-Text | Optimization of Retired Lithium

Oct 24, 2024 · Batteries | Free Full-Text | Optimization of Retired Lithium-Ion Battery Pack Reorganization and Recycling Using 3D Assessment Technology | Notes

Electrochemistry‐Driven Complete Reconstruction of Spent Lithium

Apr 3, 2025 · Wang et al. propose an electrochemistry-driven complete reconstruction (EDCR) strategy using an alkaline chloroaluminate molten salt to recover Li and transition metals from

60V Lithium Battery Pack For E-Bikes, E-Scooters,

1 day ago · Bonnen EB60-20C lithium battery pack, a dependable energy solution tailored for e-bikes, particularly optimized for city electric scooters, electric

Amazon : 60V 25Ah E-Bike Lithium Ion Battery Pack with

Jul 29, 2025 · About this item 60 Volt Lithium Ion Batteries: Rated Voltage/Capacity: 60V 25Ah. Comes with 67.2V 2A charger. Fit Motor Power: for below 1000W motor kit. Size: 310mm ×

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · Abstract - Lithium-ion batteries are used for their high energy efficiency and are frequently used by electric car manufacturers typically employ them (EVs). However, abrupt

Amazon : 60V Lithium Battery 20000mAh Pack with BMS

Aug 15, 2025 · The 16S5P 60V 20000mAH 18650 Lithium-ion Rechargeable Battery Pack is designed for use with motorcycles, scooters, and bicycles equipped with a 2000W motor. With

Cell Replacement Strategies for Lithium Ion Battery Packs

Jul 23, 2020 · The cells used in the aging comparison part of the study were deeply discharged, recovered, assembled in a new pack, and cycled. We discuss the criteria for selecting the

3-D Temperature Field Reconstruction for a Lithium-Ion Battery Pack

Dec 21, 2017 · Toward addressing this threat, this brief, for the first time, seeks to reconstruct the 3-D temperature field of a LiB pack in real time. The major challenge lies in how to acquire a

Understanding 60V Lithium Ion Batteries: Your Complete

Feb 19, 2025 · Lithium-ion batteries have become the go-to choice for powering various devices, from smartphones to electric vehicles. Among the different voltage ratings available, 60V

6 FAQs about [Reconstruction of 60v lithium battery pack]

Can lithium ion batteries be reused?

The second scenario for reuse of lithium ion battery packs examines the problem of assembling a pack for less-demanding applications from a set of aged cells, which exhibit more variation in capacity and impedance than their new counterparts.

Can lithium ion batteries be remanufactured?

The potential for remanufacturing of Lithium Ion batteries is very high, as most of the value of battery packs can be technically recovered. This work shows that the batteries need to be disassembled and tested up to cells level, in order to recover this potential value, and showed some technical difficulties in such a disassembly operation.

What are the advancements in the direct recycling of lithium ion batteries?

This review extensively discusses the advancements in the direct recycling of LIBs, including battery sorting, pretreatment processes, separation of cathode and anode materials, and regeneration and quality enhancement of electrode materials.

Are Lico 18650 batteries aging?

In the current research program, after quantifying the aging of individual LiCo 18650 cells at a statistically significant level, the evaluation process was systematically extended to small packs which represent small-scale versions of larger commercial battery systems.

What is the discharge capacity of regenerated lithium-ion battery cathode (rlco)?

The regenerated LCO (RLCO) exhibits an outstanding discharge capacity of 179.10 mAh·g −1 in the voltage range of 3.0–4.5 V at 0.5 C. The proposed strategy is an effective regeneration approach for highly-degraded LCO, thereby facilitating the efficient recycling of spent lithium-ion battery cathode materials.

Should a battery pack be replaced after an early life failure?

The first scenario, the replacement of an early life failure, addresses an important open question for maintenance of battery packs. The traditional approach in pack maintenance is to replace all cells at once to control the mismatches. This approach is clearly untenable for very large battery packs.

Learn More

- 60v lithium iron phosphate battery pack charging current

- What is the actual life of a 60v lithium iron phosphate battery pack

- 60v lead-acid lithium battery pack

- Specialized in 60v lithium battery pack for electric tools

- 60V 50A lithium battery pack

- New 60v lithium iron phosphate battery pack

- 60v lithium battery pack customization in Gothenburg Sweden

- Bangji RV lithium battery pack

- Huawei Eastern Europe pack lithium battery

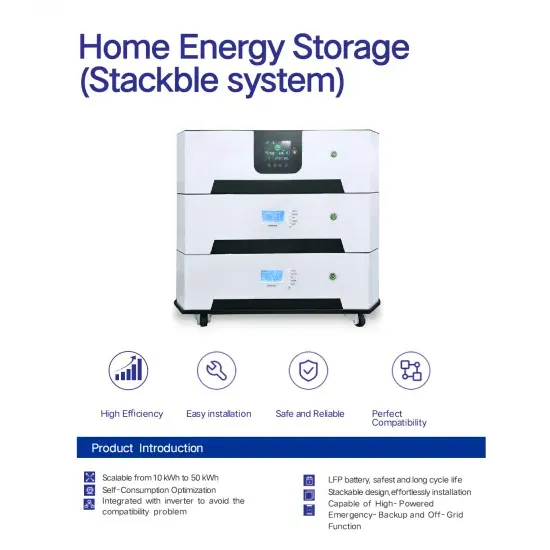

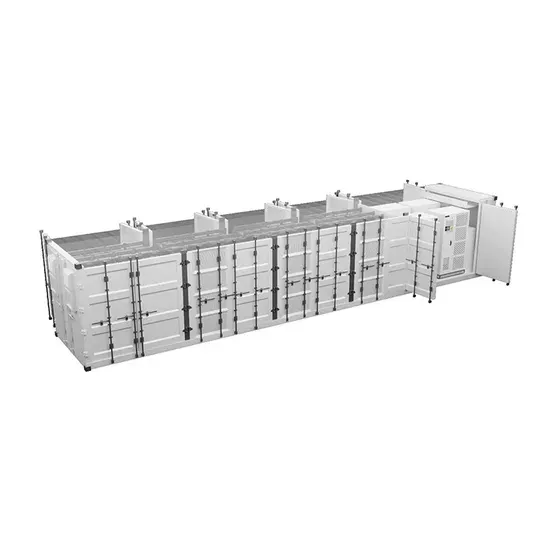

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.