Top 10 Photovoltaic Glass Brand & Manufacturers

Jul 22, 2025 · The company specializes in the production and manufacturing of photovoltaic glass and the development and construction of photovoltaic power stations. Its main products

What are the anti-corrosion processes for photovoltaic

Anti-slip walkway for photovoltaic brackets plays a vital role in the construction and operation of photovoltaic power stations. Its importance is mainly reflected in the following aspects

National Survey Report of PV Power Applications in China

Sep 8, 2021 · In addition, the catalogue of some provinces also includes items such as PV modules, silver powder for PV cells, PV power station detection, PV tracking support, PV

Grand Sunergy Powers China''s 400MW Offshore HJT Solar

Aug 21, 2024 · Grand Sunergy recently saw the booster station of the CGN Yantai Zhaoyuan 400MW offshore photovoltaic project successfully energized for the first time. This key

Photovoltaic Glass Treatments: Clarifying Terminologies and

Different treatments can enhance the mechanical performance of glass, particularly in terms of static load resistance (measured in Pascals) and hail resistance (as per IEC 61215,

Failures of Photovoltaic modules and their Detection: A Review

May 1, 2022 · The production of PV power stations and payback of initial investments are primarily dependent upon performance and lifetime of PV modules. The increase in lifetime

Technical specification requirements for photovoltaic panel glaze sealing

Aug 23, 2021 · Sealant must be applied to clean, dry, dirt-free and frost-free surfaces, and the joint surfaces must be primed if recommended by DuPont for the specific substrates. Sealant

What is photovoltaic glass? One article to understand the

In terms of application scenarios, photovoltaic glass is mostly used in photovoltaic power stations and building curtain walls; power generation glass has expanded to fields such as new energy

Revolutionary encapsulating solution of solar PV panels:

Mar 13, 2023 · Discover the role of POE Film in photovoltaic applications with EVA Film, covering its advantages in double-glass solar modules and

PHOTOVOLTAIC GLAZING IN BUILDINGS

Jul 15, 2022 · Photovoltaic glass is not perfectly transparent but allows some of the available light through Buildings using a substantial amount of photovoltaic glass could produce some of their

Revisiting Photovoltaic Module Antireflection Coatings: A

Dec 8, 2024 · The antireflection (AR) coating applied to solar glass in photovoltaic modules has remained largely unchanged for decades, despite its well-documented lack of durability.

Evaluation and Modeling of Edge-Seal Materials for

Sep 30, 2013 · We demonstrate how a thin film of Ca deposited on a glass substrate laminated to another piece of glass can be used to evaluate edge seal materials. This method is

白皮书英文版_复制

Jan 19, 2024 · Here are main reasons for the change: the power consumption in coastal areas is large, and the development of solar farm is limited by land resources (centralized power

Reassessment of the potential for centralized and distributed

Jan 1, 2023 · This study re-estimated the installed potential of centralized large-scale and distributed small-scale photovoltaic power stations in 449 prefecture-level cities in China

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

DOUBLE-GLASS PHOTOVOLTAIC MODULE AND SOLAR

Jul 29, 2020 · Description [0001] The invention relates to a double-glass photovoltaic module, a solar panel and photovoltaic power station. [0002] Single-glass photovoltaic modules are

Ground Photovoltaic Power Station Sealing Strip PV SEALS

High Elasticity & Impact Resistance The material absorbs shocks from wind forces or installation impacts, protecting glass panels from scratches or breaks. It accommodates thermal

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · A failure of growing importance is the defect in the glass layer (s) of glass-glass PV modules. In this research, an experimental glass repair technique for glass-glass PV modules

Sealing Glass in Photovoltaic Power Stations Key Benefits

Photovoltaic power stations rely on sealing glass to protect solar panels from environmental stressors like moisture, dust, and temperature fluctuations. Think of it as the "sunscreen" for

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

Photovoltaic Glass: A Sustainable and Innovative

Aug 4, 2020 · Photovoltaic glass is a sustainable building material that can generate electricity while also providing light and insulation. It is a great option

PowerPoint 演示文稿

Aug 12, 2024 · Our products cover high-quality float glass, automotive glass, energy-saving architectural glass, photovoltaic glass, new energy power station, photovoltaic film, lithium

Fault diagnosis of photovoltaic modules: A review

Jun 1, 2025 · The fault diagnosis technology of photovoltaic (PV) components is very important to ensure the stable operation of PV power station. The application of intelligent fault detection

SolarSpace Single Glass Photovoltaic Modules

Comply with local safety regulations (e.g., for operating power stations) and other system modules, including wiring and cables, connectors, charge regulators, inverters, batteries,

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

6 FAQs about [Photovoltaic power station is sealing glass]

Are glass-glass PV modules a problem?

Unfortunately, glass-glass PV modules are, similar to regular PV modules, subject to early life failures. A failure of growing concern are defects in the glass layer (s) of PV modules. The scale of decommissioned PV modules with glass defects will increase with the development of solar PV energy [ 7 ].

Can edge seal materials be used in photovoltaic applications?

Here, using a Ca film deposited on a glass substrate, we demonstrate the evaluation of edge seal materials in a manner that effectively duplicates their use in a photovoltaic application and compare the results with standard methods for measuring water vapor transport.

Why do PV modules need glass panels?

The replacement of the back sheet layer with a glass panel drastically reduces the proneness to water penetration. Ingress of water (vapor) at glass-glass PV modules is negligible and restricted to the edge area only [ 18 ].

How thick is a glass-glass PV module?

2.2. Glass characteristics Glass-glass PV modules generally use 2–3 mm thick glass layers, since thicker glass layers negatively impact the module's weight and costs, while trends are to reduce glass thickness to below 2 mm [ 10 ].

How do glass defects affect a PV system?

Glass defects impact the economic performance of a PV system in multiple ways. The most obvious effect is the potential (in)direct performance loss of PV modules, which results in reduced economic revenues. Secondly, PV modules that suffer from glass defects may no longer meet safety requirements, therefore these modules are replaced.

Does glass defect reparation damage PV cells?

Furthermore, the research analyzed the economic and energetic impact of glass defect reparation in comparison with regular substitution. We found that glass-glass PV modules which endured glass defects did not show performance loss, nor internal damage to the PV cells.

Learn More

- Mobile base station equipment photovoltaic power generation system room electrical

- The largest photovoltaic energy storage power station in Nepal

- Commercial photovoltaic energy storage power station

- Photovoltaic energy storage power station new energy vehicle

- Comparison of photovoltaic power generation with power generation glass

- Tender for photovoltaic power generation system of communication base station in Cote d Ivoire

- Construction of solar photovoltaic power station for communication base station

- Liechtenstein communication base station photovoltaic power generation system quotation

- Romania new energy photovoltaic power generation glass clean energy

Industrial & Commercial Energy Storage Market Growth

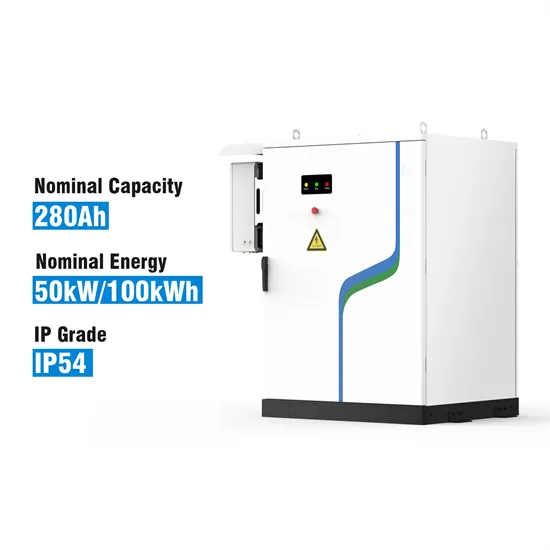

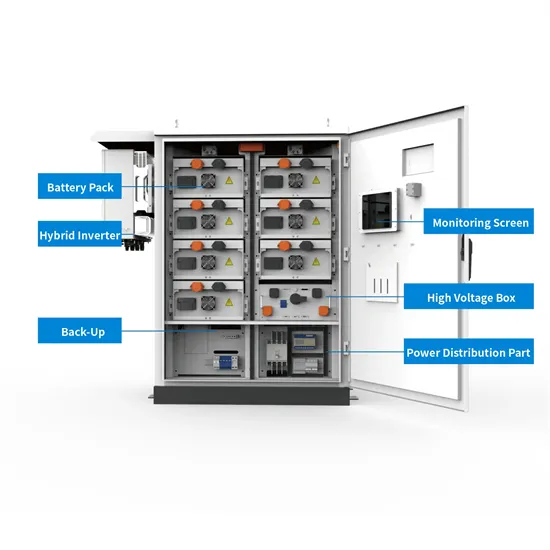

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

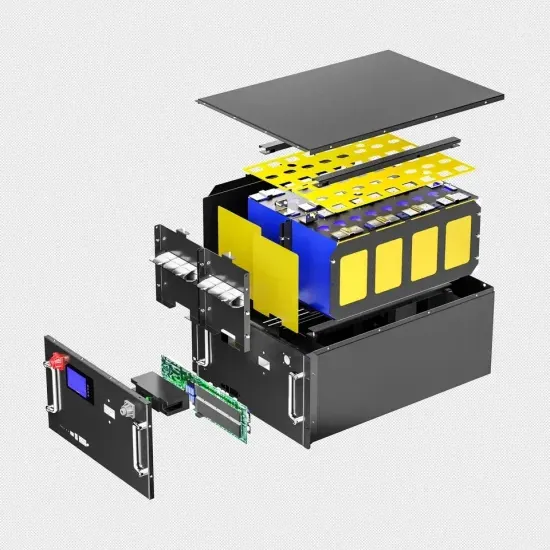

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.