How to use titanium lithium battery for solar energy

Jul 20, 2024 · 2.1. Composition and Characteristics Titanium lithium batteries represent a significant innovation in battery technology, merging the properties of titanium and lithium to

How is Handan Gree titanium energy storage battery?

Aug 30, 2024 · 1. Handan Gree titanium energy storage battery is a cutting-edge technology with several advantages: 1. Enhanced safety due to the stable chemical properties of titanium, 2.

New-generation iron–titanium flow batteries with low cost

Apr 15, 2022 · New-generation iron–titanium flow battery (ITFB) with low cost and high stability is proposed for stationary energy storage, where sulfonic acid is ch

Lithium titanium disulfide cathodes | Nature Energy

Feb 19, 2021 · It is now almost 50 years since the first rechargeable lithium batteries, based on the reversible intercalation of lithium into layered structured titanium disulfide, were conceived.

Titanium materials as novel electrodes in sodium ion capacitors

Oct 15, 2023 · The quest for efficient, profitable and worthwhile energy storage devices has led to extended research for alternative electrode materials capable of efficient activity. Sodium ion

How about Gree energy storage titanium battery | NenPower

Jun 21, 2024 · Gree energy storage titanium battery represents a significant development in the renewable energy sector. 1. These batteries offer high energy density, which enhances the

Anodic TiO2 nanotubes: A promising material for energy

Dec 1, 2022 · Owing to the high surface area combined with the appealing properties of titanium dioxide (TiO2, titania) self-organized layers of TiO 2 nanotubes (TNT layers) produced by

Aqueous titanium redox flow batteries—State-of

Oct 10, 2022 · Keywords: energy storage, redox flow batteries, titanium, kinetics, solvation, energy storage (batteries) Citation: Ahmed SIU, Shahid M and

Vanadium-titanium battery energy storage

The vanadium flow battery sector received a boost this week with a trio of announcements from Invinity, AMG and CellCube. at its subsidiary AMG Titanium. Basic engineering for the plant

Lithium-rich layered titanium sulfides: Cobalt

Apr 1, 2020 · In the context of efforts to develop at the same time high energy density cathode materials for lithium-ion batteries with low content of critical elements such as cobalt and new

How is Vanadium Titanium Energy Storage? | NenPower

Aug 21, 2024 · Vanadium titanium energy storage systems utilize the principles of redox flow batteries, enabling efficient energy storage and release This method relies on two key

Vanadium-titanium battery energy storage

The project''''s second phase mainly builds 100MW/200MWh energy storage facilities and ancillary facilities, equipped with 58 sets of lithium iron phosphate battery containers and 1 set of

Development of titanium-based positive grids for lead acid batteries

Dec 1, 2023 · Lead acid batteries suffer from low energy density and positive grid corrosion, which impede their wide-ranging application and development. In light of these challenges, the use of

Titanium Lithium Batteries: Applications, Future

Feb 14, 2025 · The energy storage industry is evolving rapidly, and among the emerging technologies, titanium lithium batteries (LTO) are gaining significant

Review on titanium dioxide nanostructured electrode

Feb 1, 2024 · These advancements, particularly the structural, porosity, phase and conductivity optimizations, play a prominent role on the energy storage, charging time and life span of the

Why Industrial Parks Are Betting Big on Titanium Battery Energy Storage

Oct 1, 2024 · As manufacturing zones globally face mounting pressure to reduce carbon footprints and stabilize energy costs, titanium-based storage solutions are emerging as the dark horse of

Improved titanium-manganese flow battery with high

Feb 28, 2022 · Manganese-based flow battery is desirable for electrochemical energy storage owing to its low cost, high safety, and high energy density. However, lon

Low‐Cost Titanium–Bromine Flow Battery with

Nov 1, 2020 · Herein, a titanium–bromine flow battery (TBFB) featuring very low operation cost and outstanding stability is reported. In this battery, a novel

Highly Stable Titanium-Manganese Single Flow Batteries for

Jun 7, 2021 · Request PDF | Highly Stable Titanium-Manganese Single Flow Batteries for Stationary Energy Storage | Manganese-based flow batteries have attracted increasing

6 FAQs about [Titanium battery for energy storage]

How much does an iron–titanium flow battery cost?

With the utilization of a low-cost SPEEK membrane, the cost of the ITFB was greatly reduced, even less than $88.22/kWh. Combined with its excellent stability and low cost, the new-generation iron–titanium flow battery exhibits bright prospects to scale up and industrialize for large-scale energy storage.

How stable are iron–titanium flow batteries?

Conclusion In summary, a new-generation iron–titanium flow battery with low cost and outstanding stability was proposed and fabricated. Benefiting from employing H 2 SO 4 as the supporting electrolyte to alleviate hydrolysis reaction of TiO 2+, ITFBs operated stably over 1000 cycles with extremely slow capacity decay.

Are lithium ion batteries a good energy bank?

A lot of work has been conducted in Lithium ion batteries in general including Li-S, Li-ion and Lithium air batteries. Lithium-ion batteries have been successfully employed as energy banks in various technological devices. Their performance and strength are unsatisfactory in most high-energy consuming applications.

What are lithium ion batteries?

Lithium ion batteries (LIBs) are the mostly used rechargeable energy storage devices that play a role in both the electric vehicles and the renewable electric power production sector [15, 18].

What are the advancements of lithium batteries?

Thus, the advancements of lithium batteries, particularly on the battery cycling and underlying energy storage reactions, lies on the optimization of the structural, architectural and composition of the electrode materials [, , ].

Is titanium dioxide a good electrode material for lithium batteries?

Nanostructured Titanium dioxide (TiO2) has gained considerable attention as electrode materials in lithium batteries, as well as to the existing and potential technological applications, as they are deemed safer than graphite as negative electrodes.

Learn More

- What are the advantages of vanadium titanium battery energy storage

- Which energy storage battery is good in Abuja

- Fixed energy storage battery cabinet photovoltaic production

- How many volts does the energy storage battery discharge

- Kosovo Monterrey Base Station Energy Storage Battery System

- Energy storage battery transportation requirements

- The purpose and function of energy storage battery containers

- Communication base station energy storage battery for sale

- Freetown lithium iron phosphate energy storage battery

Industrial & Commercial Energy Storage Market Growth

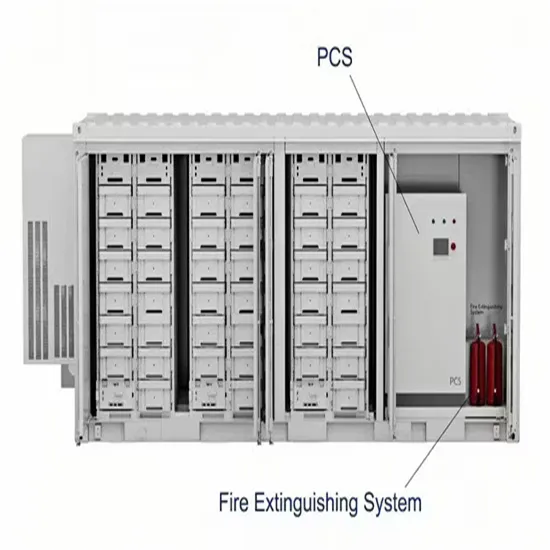

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

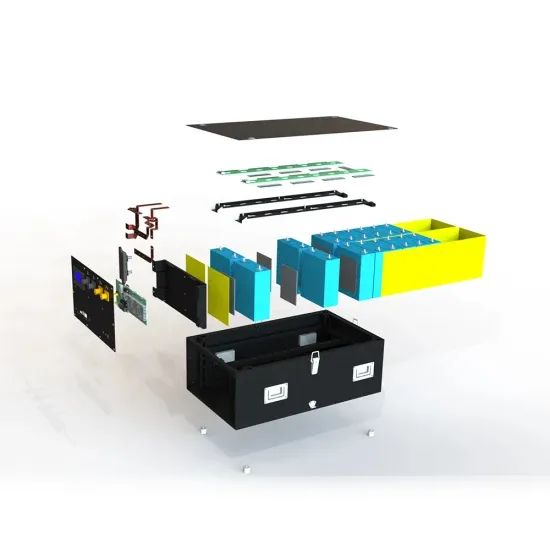

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.