Energy Storage Battery Transport Units: The Unsung Heroes

Dec 2, 2023 · Who Cares About Battery Transport? (Spoiler: You Should) Let''s start with a shocking fact: over 60% of lithium-ion battery fires occur during transportation. If that doesn''t

What You Need to Know About Transporting Lithium Batteries

Conclusion Transporting lithium batteries in accordance with ADR requires close attention to detail and strict compliance with safety regulations. This includes packaging standards to

Risk analysis for marine transport and power

Jan 1, 2024 · Therefore, at this stage, numerical methods are mainly used to simulate the TR and its propagation law in the process of large-scale battery storage and transport, and then give

How to Transport Lithium Batteries Safely –

Jul 31, 2025 · Transporting lithium batteries safely is crucial due to their energy density and potential hazards if mishandled. Whether you''re transporting

Energy storage technology and its impact in electric vehicle:

Jan 1, 2025 · The desirable characteristics of an energy storage system (ESS) to fulfill the energy requirement in electric vehicles (EVs) are high specific energy, significant storage capacity,

Battery guidance document

Feb 3, 2025 · Although some lithium and sodium ion batteries are eligible for transportation as Section II and exempted from certain labelling, packing and documentation requirements,

Lithium battery transport: all you need to know

Dec 20, 2022 · The growing demand for electrification has led to the introduction of regulations, classifications and certifications for lithium battery transport.

White Paper The Future of Transportation

Nov 2, 2023 · Labeling, marking and information requirements light means of transport (LMT) bateries. Each category h ic databases, and second life data sets. These requirements aim

Understanding EV Battery Warehousing Safety

Oct 17, 2024 · EV battery warehousing safety regulations are designed to mitigate the unique risks associated with storing large quantities of lithium-ion battery

Lithium battery energy storage cabinet air transport

Lithium battery energy storage cabinet air transport requirements 2020 Lithium Battery Guidance Document Transport of Lithium Metal and Lithium Ion Batteries Revised for the 2020

Large-scale energy storage for carbon neutrality: thermal energy

Oct 1, 2024 · Thermal Energy Storage (TES) systems are pivotal in advancing net-zero energy transitions, particularly in the energy sector, which is a major contributor to climate change due

Safety Requirements for Transportation of Lithium

Jul 17, 2017 · Batteries are classified into primary and secondary forms. A primary (non-rechargeable) cell or battery cannot be recharged and is discarded after the charge is spent.

Battery Energy Storage储能电池及系统 System

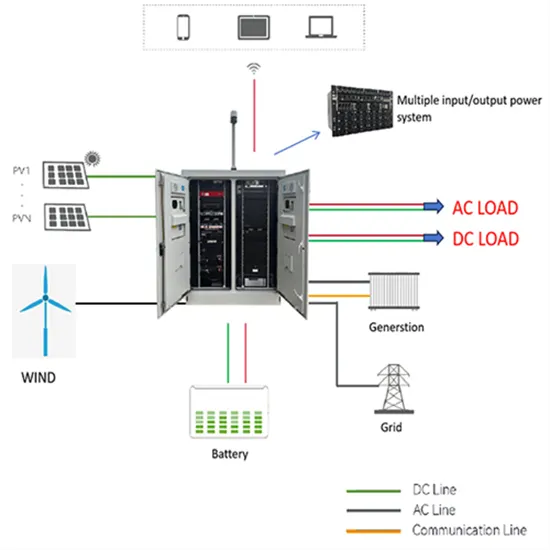

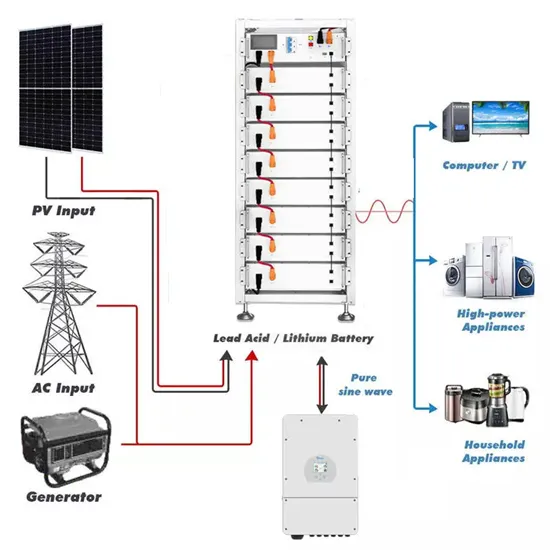

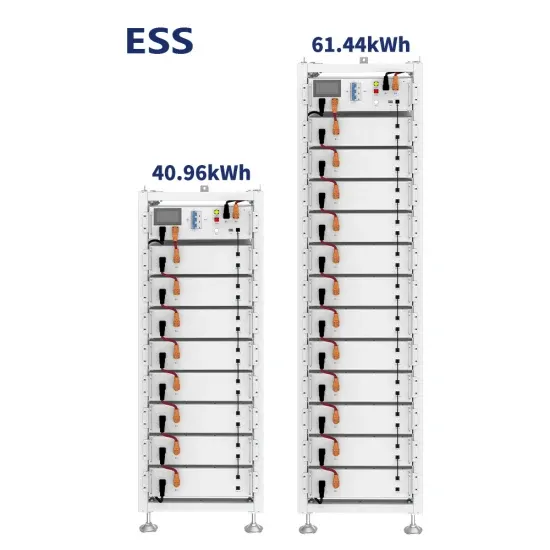

Jun 12, 2023 · Energy储能系统(ESS) Storage System In recent years, the trend of combining electrochemical energy storage with new energy develops rapidly and it is common to move

Safety Requirements for Transportation of Lithium

Jul 17, 2017 · This is especially true of lithium batteries, which have been identified as dangerous goods when they are transported. This paper reviews the international and key national (U.S.,

Your Guide to Battery Energy Storage Regulatory Compliance

4 days ago · As the battery energy storage market evolves, understanding the regulatory landscape is critical for manufacturers and stakeholders. This guide offers insights into

6 FAQs about [Energy storage battery transportation requirements]

Are battery energy storage systems safe aboard ships?

In recent months, Gard has received numerous inquiries about the safe transportation of battery energy storage systems (BESS) aboard ships. This article addresses some of the key risks, regulatory requirements, and recommendations for shipping such cargo.

What are EV battery warehousing safety regulations?

EV battery warehousing safety regulations are designed to mitigate the unique risks associated with storing large quantities of lithium-ion battery packs. These regulations typically cover several key areas: Requirement: Maintaining specific room temperatures and humidity ranges for battery storage.

What are the requirements for lithium ion battery storage?

These regulations typically cover several key areas: Requirement: Maintaining specific room temperatures and humidity ranges for battery storage. The optimal storage temperature for lithium-ion batteries is within the recommended temperature range (typically 15°C to 25°C) to preserve battery life and reduce the risk of thermal runaway.

Is there a need to consolidate standards & regulations for battery shipments?

There is definitely a need to consolidate norms and regulations. Furthermore, there is a need to consolidate safety testing requirements for battery shipments that not only cover cells, but the batteries themselves and the products (equipment, systems).

Are lithium-ion batteries safe to transport?

To address these concerns, the United Nations (UN) has established the UN Model Regulations for the transport of dangerous goods. Within these regulations, UN3536 specifically addresses lithium-ion battery installations in transport. Compliance with UN3536 is a mandatory requirement for the safe and legal transport of containerised BESS units.

What is a battery energy storage system?

Battery energy storage systems (BESS) are the most common type of ESS where batteries are pre-assembled into several modules. BESS come in various sizes depending on their application and their usage is expected to rise considerably in coming years.

Learn More

- Ecuador energy storage battery air transport power requirements

- Energy storage equipment transportation and related requirements

- Battery energy storage box material requirements

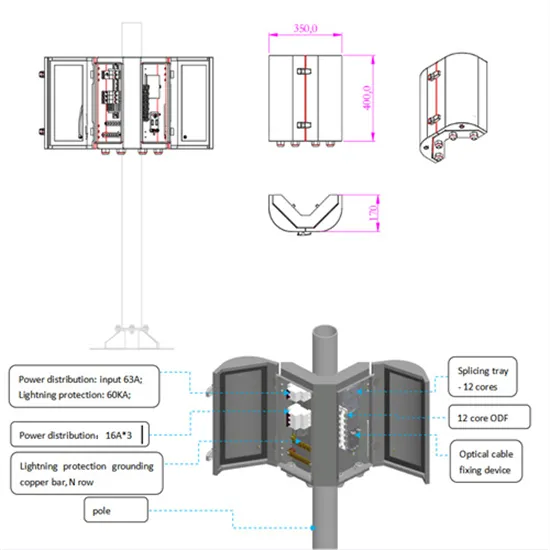

- Requirements for battery energy storage systems for high-altitude communication base stations

- How much does it cost to transport lithium battery energy storage cabinets by air

- Thailand photovoltaic energy storage battery company

- What is the process for replacing the battery energy storage system of a communication base station

- Communication base station battery energy storage system 7900

- Phnom Penh energy storage battery price

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.