Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · Amp Alternating Current Battery Energy Storage System Battery Monitoring System Bill of Lading Containerized EnergyStorage System Commercial & Industrial Direct Current

Battery energy storage box standard specification

A battery energy storage system (BESS) is an electrochemical device that charges (or collects energy) from the grid or a power plant and then discharges that energy at a later time to

What are the materials for energy storage battery boxes?

Feb 4, 2024 · 1. The materials for energy storage battery boxes include a variety of durable substances, such as 1. polymer composites, 2. aluminum alloys, 3. steel, and 4.

Material requirements for energy storage battery boxes

As the photovoltaic (PV) industry continues to evolve, advancements in Material requirements for energy storage battery boxes have become critical to optimizing the utilization of renewable

Material requirements for energy storage battery boxes

When you''re looking for the latest and most efficient Material requirements for energy storage battery boxes for your PV project, our website offers a comprehensive selection of cutting

Battery Storage Box Materials: The Ultimate Guide for Safety

Whether you''re storing EV batteries or portable power banks, the materials used in these boxes directly impact safety, durability, and even regulatory compliance. Let''s crack open this topic

Battery energy storage box material requirements and

Battery energy storage box requirements and standards material container, that can store and discharge electrical energy and safety requirements for battery energy storage systems. This

Battery Energy Storage System Installation requirements

Mar 16, 2021 · AS/NZS 5139:2019 was published on the 11 October 2019 and sets out general installation and safety requirements for battery energy storage systems. This standard places

6 FAQs about [Battery energy storage box material requirements]

What should be included in a contract for an energy storage system?

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

What are the requirements for external battery storage equipment?

y standards None applicable at present.3.2.3 Separate specific requirementsExternal enclosure of the battery storage equipment is metallic material having a minimum thickness not less than 0.20 mm at any point, or is a polymeric material classified as 5VA according to IEC 60695-11-20:2015 (provided that the test sample used f

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

How many volts can a battery store?

r use. The battery contains lithium as part of the energy storage medium.The battery storage equipment has a rated capacity of equal to or greater than 1kWh an up to and including 200kWh of energy storage capacity when measured at 0.1C.For battery modules, the output voltage upper limit is 1500Vd.c. (noting that such parts ar

Can a battery storage system increase power system flexibility?

sive jurisdiction.—2. Utility-scale BESS system description— Figure 2.Main circuit of a BESSBattery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, suc

Learn More

- Which battery energy storage box is better

- Battery energy storage box wholesaler in Kyrgyzstan

- Fire protection requirements for battery energy storage stations

- Quality requirements for energy storage battery cabinets

- Czech Brno Battery Energy Storage Box Customization Company

- Ecuador energy storage battery air transport power requirements

- Material of Maputo photovoltaic energy storage box

- Battery energy storage box electrophoresis

- Battery energy storage box processing equipment

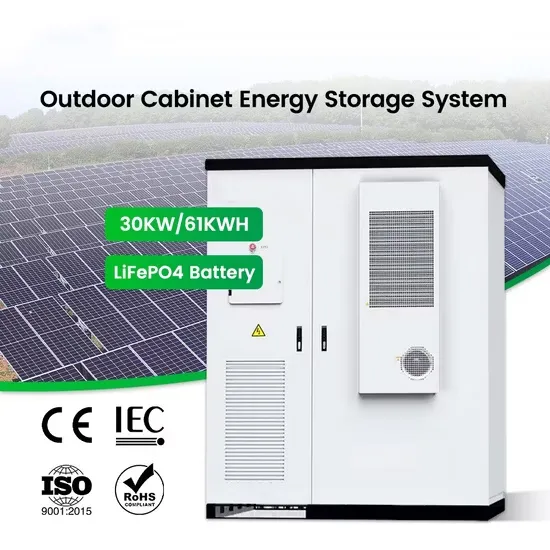

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.