Performance investigation of solution-processed semi

Nov 1, 2024 · Chen established a comparative experimental apparatus for c-Si photovoltaic cells and common windows [12]. The study results reveal that the optimal energy-saving benefits

Lanxin Showcases Smart Logistics Solutions for the Photovoltaic

At the 2024 SNEC in Shanghai, Lanxin unveiled its cutting-edge smart logistics solutions tailored specifically for the photovoltaic (PV) industry. These innovations, which address key stages of

Photovoltaic Glass: Solutions to Make the World

Aug 4, 2020 · Photovoltaic Glass Building-integrated photovoltaics (BIPV) are photovoltaic materials that are used to replace conventional building materials

Ultra-thin PV Glass-Quantum Materials Technology (Suzhou)

The standard PV panel is made of a single layer tempered glass of 3.2mm thick, with a transparent or colored PET back sheet. The total thickness of module is between 4.5-5mm.

PHOTOVOLTAIC SOLUTIONS FOR PUBLIC

Nov 8, 2022 · The use of free green energy produced from glass-glass photovoltaic modules used as a bus stop canopy significantly reduces the cost of electricity bills and CO2 emissions. ML

Photovoltaic Glass Loading and Transportation Best

The answer lies in the fragile nature of photovoltaic (PV) glass – the backbone of solar energy systems. As global solar capacity grows at 15% annually (IRENA 2023), efficient photovoltaic

Integrating Renewable Energy in Transportation:

Mar 13, 2024 · The photovoltaic noise barrier (PVNB), a solar noise barrier, is an innovative integration of transportation and renewable energy. It is primarily

Innovative Glass Photovoltaic Solutions: Harnessing Solar

Apr 20, 2023 · There are several types of glass photovoltaic materials that cater to various applications and energy requirements. Among the most common are crystalline silicon-based

Photovoltaic pavement and solar road: A review and

Feb 1, 2023 · To deal with this issue, the concept of photovoltaic (PV) pavement is emerging [28], [29]. It regards the modified photovoltaic modules as one part of the road structure, equipped

Photovoltaic Applications | Photovoltaic Research | NREL

Apr 3, 2025 · Photovoltaic Applications At NREL, we see potential for photovoltaics (PV) everywhere. As we pursue advanced materials and next-generation technologies, we are

Managing photovoltaic Waste: Sustainable solutions and

Nov 15, 2024 · The global shift to clean energy has resulted in a significant increase in photovoltaic (PV) panel installations. However, with their limited lifespan

Optimizing Photovoltaic Panel Transportation Routes:

Did you know that 23% of solar project delays in 2024 were linked to transportation issues? Photovoltaic (PV) panels, with their fragile glass surfaces and complex electrical components,

Sustainable photovoltaic recycling to mitigate

Dec 31, 2024 · This article studies how to enhance the deployment efficiency of photovoltaics (PVs) and reduce the environmental pollution process of end-of

Optimizing Photovoltaic Panel Transportation Routes:

Why Photovoltaic Panel Transportation Routes Demand Specialized Attention Did you know that 23% of solar project delays in 2024 were linked to transportation issues? Photovoltaic (PV)

Ultra-thin Rolled Photovoltaic Glass – New Way

Jun 16, 2024 · The development of thinner rolled photovoltaic glass poses many challenges in production. To improve the quality of ultra-thin rolled glass, new

Recent trends in photovoltaic technologies for sustainable

Jul 1, 2023 · Utilizing solar photovoltaic energy to energize the vehicle is an exciting approach in transportation to achieve United Nations sustainable development goals (UN SDG).

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Glass substrates as GESSNER''s solution for photovoltaic

CRANEGLAS ™ glass nonwovens are specifically designed as a uniform web formation to allow light to pass through without interfere. This patented technology provides a highly transparent

Shining a Light on PV Panel Recycling: Why It

Oct 26, 2024 · The collection and transportation of end-of-life photovoltaic (PV) panels is a crucial step in the recycling process. PV panel manufacturers,

Glass-Glass Modules: The Revolution for Solar Installers –

Dec 18, 2024 · Glass-glass modules provide you as an installer with a reliable and durable solution for your customers'' photovoltaic systems. With the dual glass layer, these modules

Advancements in Photovoltaic Glass Technology

Aug 19, 2025 · Implementing PV glass technology requires careful planning, financial investment, and a willingness to adapt to new ways of operating. It is through collaboration, knowledge

A review on photovoltaic combined vacuum glazing: Recent

May 1, 2023 · Recently, PV combined vacuum glazing has become a popular research topic and attracted researchers to resolve the drawbacks of commonly used glazing products. In the last

Which is easier to transport photovoltaic panels or glass

What is Photovoltaic Glass? Photovoltaic glass is probably the most cutting-edge new solar panel technologythat promises to be a game-changer in expanding the scope of solar. These are

What is the Difference Between Solar Photovoltaic Glass and Float Glass?

May 30, 2024 · Photovoltaic (PV) glass, used in solar panels, features special coatings for efficiency and durability, while float glass, used in construction and automotive industries, is

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

6 FAQs about [Photovoltaic glass transportation solution]

What is Photovoltaic Glass integration?

Photovoltaic glass integration transforms factory roofs and walls into power-generating assets while maintaining structural integrity and functionality.

How does Photovoltaic Glass impact the future of manufacturing?

As the world continues to prioritize sustainability and combat climate change, the role of photovoltaic glass in shaping the future of manufacturing becomes increasingly prominent. The integration of PV glass into factory infrastructure aligns with the growing emphasis on renewable energy, energy efficiency, and green building practices.

How can we improve the efficiency of photovoltaic (PSC) systems?

In this manner, we can facilitate a more effective integration of PSCs into our daily lives. The accumulation of pollution and any kinds of contamination on the glass cover of the solar cell affects the efficiency of the photovoltaic (PV) systems.

Why is PV glass important in manufacturing?

Integrating PV glass into factory design enables manufacturing facilities to optimize energy consumption by leveraging both passive and active properties. The insulating characteristics of PV glass help maintain stable indoor temperatures, reducing the energy required for heating and cooling.

How do specialized coatings improve light transmission to photovoltaic cells?

Propagation of light waves through (a) multilayers and (b) single glass layer (n s>nir). minimizing reflection effects. be better solved via computational methods. energy systems. These specialized coatings and materials are designed to minimize dirt accumulation and enhance light transmission to photovoltaic cells. The develop-

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Learn More

- Photovoltaic glass transportation component height

- Photovoltaic glass factory solution

- The relationship between silicon sulfide and photovoltaic glass

- Andorra Photovoltaic Glass House BESS

- Photovoltaic power generation glass applications

- Photovoltaic heat-enhanced glass

- Madagascar photovoltaic glass greenhouse processing

- Thimphu anti-fouling photovoltaic glass

- Huawei Mozambique Photovoltaic Glass Factory

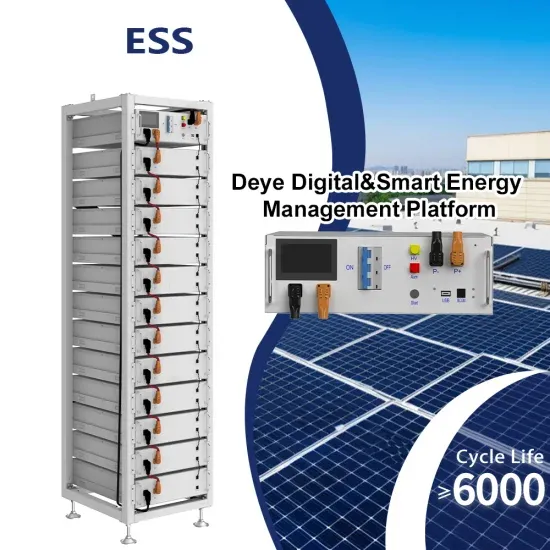

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.