Energy storage systems: a review

Sep 1, 2022 · The FES system is a mechanical energy storage device that stores the energy in the form of mechanical energy by utilising the kinetic energy, i.e., the rotational energy of a

A review of energy storage types, applications and recent

Feb 1, 2020 · Recent research on new energy storage types as well as important advances and developments in energy storage, are also included throughout.

4 most common types of mechanical energy storage

May 17, 2023 · This article discusses the four most common types of mechanical energy storage systems: springs, flywheels, capacitors, and compressed air. Learn about their advantages,

Sustainable and Flexible Energy Storage Devices:

Dec 9, 2022 · Hence, this review is focused on research attempts to shift energy storage materials toward sustainable and flexible components. We would like

Energy Storage Devices for Mechanical Equipment Key

Energy storage devices act like shock absorbers for power systems – they smooth out supply-demand mismatches while protecting sensitive machinery. Let''s break down the top solutions

The Ultimate Guide to Mechanical Battery and Energy Storage

Jan 9, 2025 · As we move toward sustainability, mechanical batteries offer a new energy storage solution. Learn about their mechanics, benefits, and challenges.

Differences between equipment energy storage and

Energy storage systems are used by a range of application areas with various efficiency, energy density, and cost requirements. This means that the options for effectively comparing energy

MALLA REDDY COLLEGE OF ENGINEERING

Aug 23, 2023 · The use of bio-electrochemical devices or bio-batteries based on biological systems will represent a breakthrough for the electronics industry in developing greener and

A review of the energy storage system as a part of power

Aug 1, 2024 · However, the multi-timescale dynamics of the energy storage system that differs from the traditional synchronous generators results in the challenges for the accurate and

Elastic energy storage technology using spiral spring devices

Dec 1, 2023 · Spiral spring energy storage harvests and stores random mechanical energy. Harvesting and storing energy is a key problem in some applications. Elastic energy storage

6 FAQs about [Energy storage device for mechanical equipment]

What are mechanical energy storage devices?

Mechanical energy storage devices are systems that capture energy in mechanical form for later use, using various methods such as gravitational potential, kinetic energy, or elastic deformation. These devices include technologies like pumped hydroelectric storage, flywheels, and compressed air energy storage. 1.

What are the different types of mechanical energy storage systems?

This article discusses the four most common types of mechanical energy storage systems: springs, flywheels, capacitors, and compressed air. Learn about their advantages, limitations, and applications. Mechanical energy storage is an essential component of many energy systems.

How do mechanical energy storage systems work?

Mechanical energy storage systems take advantage of kinetic or gravitational forces to store inputted energy. While the physics of mechanical systems are often quite simple (e.g. spin a flywheel or lift weights up a hill), the technologies that enable the efficient and effective use of these forces are particularly advanced.

Are mechanical energy storage systems efficient?

Mechanical energy storage systems are very efficient in overcoming the intermittent aspect of renewable sources. Flywheel, pumped hydro and compressed air are investigated as mechanical energy storage. Parameters that affect the coupling of mechanical storage systems with solar and wind energies are studied.

Can mechanical energy storage systems be used as a solution?

Hence, mechanical energy storage systems can be deployed as a solution to this problem by ensuring that electrical energy is stored during times of high generation and supplied in time of high demand. This work presents a thorough study of mechanical energy storage systems.

What are the different types of energy storage technologies?

Energy storage technologies with high energy capacity like PHS, compressed air energy storage (CAES), and gravity energy storage (GES) can provide excellently the black start service to the grid. There are six different categories of ESS, and these are: mechanical, thermal, chemical, electrochemical, electrical and hybrid system.

Learn More

- Energy storage equipment pressure device

- Common energy storage devices for mechanical equipment

- Island-type microgrid energy storage equipment

- Malta energy storage power station equipment sales

- Bulgarian industrial energy storage equipment manufacturer

- Korean phase change energy storage device

- Fiji energy-saving energy storage equipment transformation

- 70 kW energy storage equipment

- Mexican Monterrey energy storage equipment prices

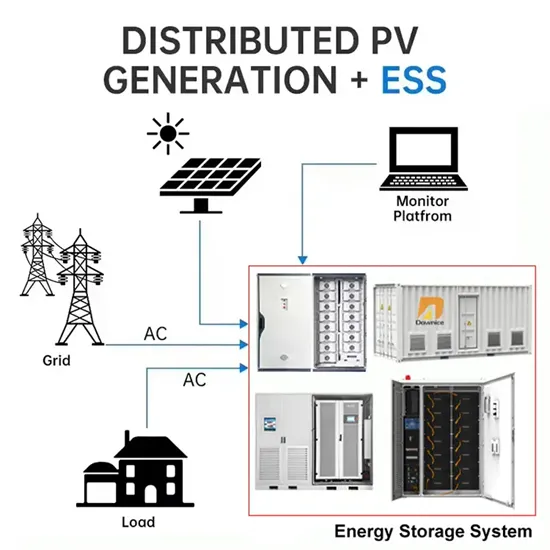

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.