Rationally Tunable Phase Change Material Thermal

Passive cooling using phase change materials (PCMs) is a promising solution to address thermal challenges for modern electronics, electric vehicles, and energy storage systems. The high

Advancing grid stability and renewable energy: Policy

Jul 4, 2025 · The evolution of policies and regulations supporting battery energy storage system (BESS) development, utilization, and sustainability to enhance resource adequacy was

Novel strategies and supporting materials applied to shape

Feb 1, 2019 · However, the tendency of organic phase change materials to leak out during the phase transition process, limits their practical applications in thermal energy storage. The

Polymer engineering in phase change thermal storage

Dec 1, 2023 · Thermal storage technology based on phase change material (PCM) holds significant potential for temperature regulation and energy storage application.

Performance analysis of phase change material using energy storage device

Jan 1, 2020 · Latent heat storage system energy is engrossed or released in order to change the phase of external fluid with the presence of Phase Change Material (PCM). The phenomenon

Experimental Study of Shape-Stabilized Phase Change

Mar 1, 2025 · Low-temperature latent heat storage based on solid–liquid phase change materials (PCMs) has become an attractive energy saving technology in many applications, especially in

Review of the heat transfer enhancement for phase change heat storage

May 10, 2024 · In this review, by comparing with sensible heat storage and chemical heat storage, it is found that phase change heat storage is importance in renewable energy utilization,

Properties and applications of shape-stabilized phase change energy

Mar 1, 2023 · Solid-liquid phase change materials (PCMs) have become critical in developing thermal energy storage (TES) technology because of their high energy storage density, high

Breakthrough semiconductor tech cuts power use by 1

Nov 7, 2024 · Reducing the energy demand of the amorphization process takes us one step closer to phase-change memory-based data storage systems in the future.

Research progress on heat transfer enhancement technology of phase

Abstract: Phase change energy storage is a technology to realize energy storage through the absorption/release of latent heat during phase change processes. It can balance the mismatch

A comprehensive investigation of phase change energy storage device

Mar 1, 2025 · A comprehensive investigation of phase change energy storage device based on structural design and multi-objective parameter optimization

Recent Advances in Phase Change Energy Storage Materials:

Jan 22, 2025 · Phase change energy storage (PCES) materials have attracted considerable interest because of their capacity to store and release thermal energy by undergoing phase

South Korea Redefines Energy Storage With a Self-Charging Device

Jan 11, 2025 · Researchers developed a device that can store solar energy and use it efficiently. Notably, the system integrates two technologies into one unit: supercapacitors, which function

South Korea Phase Change Heat Storage Material Market

Jun 5, 2025 · The South Korea Phase Change Heat Storage Material (PCHSM) market has emerged as a critical component in the nation''s pursuit of energy efficiency and sustainable

A comprehensive performance evaluation of phase change

Mar 1, 2025 · Cold thermal energy storage systems, especially those utilizing phase change materials, offer a promising solution to mitigate these challenges. This study presents a

Research progress of heat storage and heat transfer

The finding demonstrate that future research should focus on clarifying the multi-phase coupling heat transfer mechanism inside the heat storage device, improving the heat storage device''s

KAIST Develops New Phase Change Memory Device

May 20, 2024 · Professor Choi and his research group successfully developed nanometer-scale, extremely low-power phase change memory with an electrical minimization method, which is

Phase Change Energy Storage

Mar 19, 2007 · Impact Applications include: backup cooling, absorption of thermal transients, quick heating (for startups), defrosting, temperature control, cooling of portable and other

Korea Energy Storage Power: Innovations, Challenges, and

Jan 13, 2022 · With Korea aiming to achieve 20% renewable energy by 2030, energy storage systems (ESS) have become the nation''s secret sauce for balancing solar spikes and wind

Phase change material-based thermal energy storage

Aug 18, 2021 · INTRODUCTION Solid-liquid phase change materials (PCMs) have been studied for decades, with application to thermal management and energy storage due to the large

Recent developments in phase change materials for energy storage

Feb 1, 2019 · In particular, the melting point, thermal energy storage density and thermal conductivity of the organic, inorganic and eutectic phase change materials are the major

Review of the heat transfer enhancement for phase change

Mar 20, 2024 · Cascade phase change heat storage is also used; Varies structure and number of fins on the heat transfer fluid side or the phase change material side employed, too. In

Phase change material-based thermal energy storage

INTRODUCTION Solid-liquid phase change materials (PCMs) have been studied for decades, with application to thermal management and energy storage due to the large latent heat with a

Flexible Phase Change Composites with Excellent Thermal Energy Storage

Dec 5, 2024 · Phase change materials (PCMs) are used in the field of thermal management because of their ability to absorb and release thermal energy through latent heat. However,

A comprehensive review on phase change materials for heat storage

Jan 1, 2022 · Phase change materials (PCMs) utilized for thermal energy storage applications are verified to be a promising technology due to their larger benefits over other heat storage

6 FAQs about [Korean phase change energy storage device]

What is phase change heat storage?

The phase change heat storage devices of different structures are summarized and classified. The configuration theory is introduced, which has great significance to the improvement of the phase change heat storage technology. The imbalance of energy supply and demand and a series of environmental problems are associated with traditional energy.

Are phase change thermal storage systems better than sensible heat storage methods?

Phase change thermal storage systems offer distinct advantages compared to sensible heat storage methods. An area that is now being extensively studied is the improvement of heat transmission in thermal storage systems that involve phase shift . Phase shift energy storage technology enhances energy efficiency by using RESs.

Which materials store energy based on a phase change?

Materials with phase changes effectively store energy. Solar energy is used for air-conditioning and cooking, among other things. Latent energy storage is dependent on the storage medium’s phase transition. Acetate of metal or nonmetal, melting point 150–500°C, is used as a storage medium.

What are phase change energy storage materials (pcesm)?

1. Introduction Phase change energy storage materials (PCESM) refer to compounds capable of efficiently storing and releasing a substantial quantity of thermal energy during the phase transition process.

How can a phase change heat storage device improve thermal conductivity?

Or package the phase change materials in different shapes and sizes; Mixing of graphite or nanoparticles helps to enhance the low thermal conductivity of phase change materials. On the other hand, the heat storage performance is improved through optimizing the phase change heat storage device.

What is low-temperature latent heat storage based on solid-liquid phase change materials (PCMs)?

Low-temperature latent heat storage based on solid–liquid phase change materials (PCMs) has become an attractive energy saving technology in many applications, especially in energy-efficient buildings, electronic and battery thermal management, low-temperature solar energy utilization, and industrial waste heat recovery [1, 2, 3, 4].

Learn More

- Guyana Phase Change Energy Storage Device

- Togo Phase Change Energy Storage Grid

- Phase change energy storage microgrid

- Tashkent Phase Change Energy Storage Products Company

- Ngerulmud phase change energy storage products

- Spanish phase change energy storage system supplier

- Phase change energy storage power station

- Honiara Phase Change Energy Storage System Supplier

- Helsinki Photovoltaic Energy Storage Device Solution

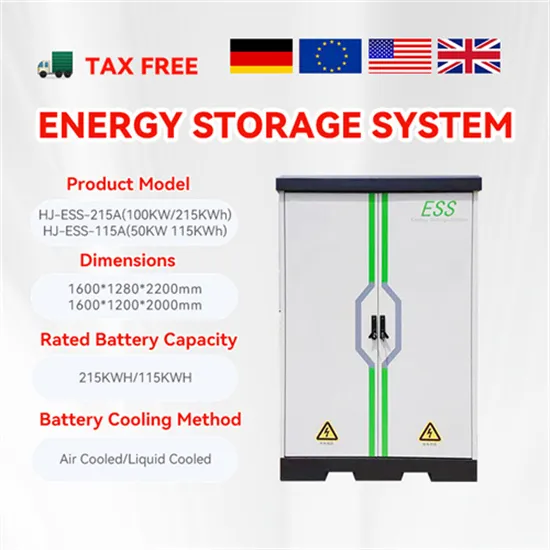

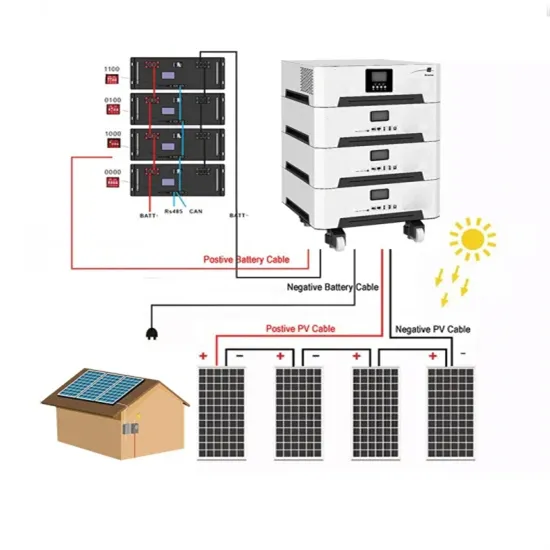

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.