About mobile collapsible photovoltaic container installation

May 7, 2025 · This paper is a guide to mobile foldable photovoltaic containers installation and operation information and features, walking renewable energy project managers, emergency

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · There are several interesting milestones to oversee when manufacturing a Battery Energy Storage Sys- tem: • Battery pack assembly and testing • PCS assembly and testing •

Hyswell Fast Delivery Customized Solar Photovoltaic Battery Container

Nov 8, 2024 · Hyswell Fast Delivery Customized Solar Photovoltaic Battery Container, Find Details and Price about Shipping Containers 20 Foot Containers from Hyswell Fast Delivery

FOREMOST Solar Containers: Efficient Solutions

Aug 15, 2025 · The first solar container functions as a transformer and can be opened on both sides with flip-up side panels to store electrical energy within

PV Container Power Battery Energy Storage System China

Nov 11, 2024 · 1, PV System requirement Daily power needed: 800KWh 2, Overall design 2.1 Solar photovoltaic power generation systems are mainly composed of photovoltaic modules,

Battery Pack Inspection Sheet

What is a battery inspection checklist? This detailed Battery Inspection Checklist ensures battery performance and safety. This checklist, which includes both visual and technical inspections,

Shanxi solar battery Inspection,Photovoltaic batteries

Aug 9, 2022 · Shanxi solar battery Inspection,Photovoltaic batteries qc,sourcing agent/Container Loading Supervision/Sample Test/Pre-Production Inspection/Company Verification/During

volytica and Sinovoltaics launch service to detect battery

Jul 12, 2024 · Sinovoltaics, a global leader in quality assurance for the battery energy storage system (BESS) and solar photovoltaic (PV) industries, has launched BESSential, a service

Mobile Solar PV Container | Portable Solar Power Solutions

High-efficiency Mobile Solar PV Container with foldable solar panels, advanced lithium battery storage (100-500kWh) and smart energy management. Ideal for remote areas, emergency

Energy Storage Solutions Inspection Checklist and Template

Aug 18, 2025 · Check the product''s power source or battery compartment for any signs of corrosion or damage. Test the product''s power on/off functionality to ensure it is working

Modular Solar Power Station Container Factory

Founded in 2016, Senta Energy Co., Ltd., located in Wuxi, Jiangsu, is a high-tech enterprise mainly engaged in new energy photovoltaic power generation and energy storage business,

Folding photovoltaic containers: Flexible and mobile solar

Dec 26, 2024 · The greatest merit of folding photovoltaic panel containers is their high degree of mobility, avoiding the large occupation of land by traditional solar power generation systems.

How to conduct quality inspection on photovoltaic cells

Whether you''re an importer or manufacturer, ensuring that the solar products you source meet your specifications are crucial. Even the slightest defects can significantly impact the solar

BATTERY INSPECTION CHECKLIST

Oct 10, 2024 · Note: Battery should be Replaced if ~ Point 2,4 & 7: Badly damage ~ Point 16: < 6,5 VDC or < 300A Battery should be Recharged if ~ All Visual Inspection OK ~ Point 16 in

Energy storage battery container factory inspection

Designing a Battery Energy Storage System (BESS) container in a professional way requires attention to detail, thorough planning, and adherence to industry best practices.

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · Unit one container for both battery and PCS), or grid- scale BESS (with dedicated containers for both batteries and PCS) •Grid frequencyin Hertz (Hz) •Ingress protection (IP)

Batteries in Photovoltaic Systems – Applications

4 days ago · Batteries: Fundamentals, Applications and Maintenance in Solar PV (Photovoltaic) Systems In a standalone photovoltaic system battery as an

National Center of Quality Inspection and Testing on

The national center belongs to the fist batch of IECEE_CB testing laboratories in China, capable of testing 12 kinds of wind turbine products, 4 kinds of PV products, and all kinds of new

20FT 40FT Container Battery Energy Storage System 500kw

Aug 18, 2025 · 20FT 40FT Container Battery Energy Storage System 500kw 1MW 2MW 3MW with 250kwh 500kwh 1mwh 2mwh 3mwh 5mwh 10mwh Lithium Battery Bank for Solar Storage

Inspection and maintenance of solar battery storage system

In order to keep your solar battery storage system running smoothly, it is important to regularly inspect and maintain the system. Here are some tips on how to do so: 1. Check the system

Photovoltaic Energy Storage System Solution to

4 days ago · There are different categories of OSI equipment up to 100 tons, which need electricity supply for normal functionality. This work carries out a photovoltaic energy storage

Energy storage battery container factory inspection

There are standards for photovoltaic system components,wind generation and conventional batteries. However,there are currently no IEEE,UL or IEC standardsthat yet pertain specifically

Battery Energy Storage System Inspection and Testing

Mar 13, 2023 · Comprehensive guidelines for inspection and testing of Battery Energy Storage Systems to ensure safety, reliability, and performance in energy storage applications.

Automated Photovoltaic Power Plant Inspection via

Oct 3, 2023 · This article addresses the design of a fully automated photovoltaic (PV) power plant inspection process by a fleet of unmanned aerial and ground vehicles (UAVs/UGVs). More

6 FAQs about [Photovoltaic container battery inspection]

When should a battery energy storage system be inspected?

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get accustomed to the BESS design and anticipate potential roadblocks that could delay the shipping procedure of the Energy Storage System.

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

How to compare battery energy storage systems?

In terms of $, that can be translated into $/kWh, the main data to compare Battery Energy Storage Systems. Sinovoltaics’ advice: after explaining the concept of usable capacity (see later), it’s always wise to ask for a target price for the whole project in terms of $/kWh and $.

Are lithium-ion batteries certified?

As mentioned in the Request for Proposal section, the UN38.3 certicate is the standard of reference when it comes to Lithium-ion battery transporta- tion. However, if you are using customized batteries for your project, it is possible that the batteries transported are not UN38.3 certied at the time of transportation.

Should lithium batteries be manufactured in a clean room?

Sinovoltaics’ advice:due to the reactive nature of lithium with moisture in the air, it is recommended to do battery manufacturing in a clean room in order to ensure a controlled environment (humidity rate, tem- perature, dust etc). Such standards also ensure prop- er protection and equipment for the operators. Clean

Learn More

- Container photovoltaic energy storage lithium battery solution

- Identification of actual battery capacity in photovoltaic container system

- What is the capacity of the container photovoltaic energy storage battery warehouse

- Photovoltaic container system program battery

- What is the use of battery optimization in photovoltaic container systems

- How to know the battery life of photovoltaic container system

- Photovoltaic cells for Portugal s container battery factory

- What are the components of the energy storage battery container

- How big a lead-acid battery should I use for a 100W photovoltaic panel

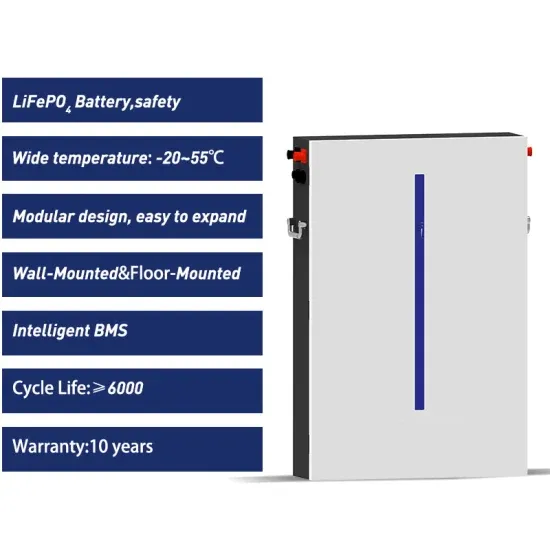

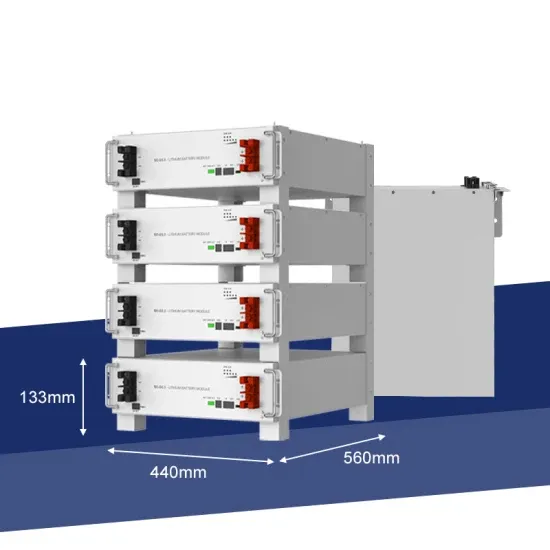

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.