Folding photovoltaic containers: Flexible and mobile solar

Dec 26, 2024 · The greatest merit of folding photovoltaic panel containers is their high degree of mobility, avoiding the large occupation of land by traditional solar power generation systems.

Understanding Depth of Discharge (DoD) and Its Impact on Photovoltaic

Dec 9, 2024 · Whether you''re using this system in a residential or commercial setup, understanding how deep discharges affect your batteries will help ensure that your

Design and Cost Analysis for a Second-life Battery-integrated

Jan 1, 2024 · Pingen Chen** Design and Cost Analysis for a Second-life Battery-integrated Photovoltaic Solar Container for Rural Electric Vehicle Charging 1086 Magdy Abdullah Eissa

Grid-connected photovoltaic battery systems: A

Dec 15, 2022 · Due to the target of carbon neutrality and the current energy crisis in the world, green, flexible and low-cost distributed photovoltaic power generation is a promising trend.

Container Energy Storage System: All You Need to Know

Apr 23, 2024 · What is Container Energy Storage? Container energy storage, also commonly referred to as containerized energy storage or container battery storage, is an innovative

Container Photovoltaic Power System Market

Feb 9, 2025 · For instance, Trina Solar''s 20-foot container PV systems integrate pre-configured solar panels, inverters, and battery storage with standardized mounting interfaces, cutting

Comprehensive Guide to Key Performance Indicators of Energy Storage Systems

Mar 15, 2025 · Understanding key performance indicators (KPIs) in energy storage systems (ESS) is crucial for efficiency and longevity. Learn about battery capacity, voltage, charge

Review on photovoltaic with battery energy storage system

May 1, 2023 · This paper aims to present a comprehensive review on the effective parameters in optimal process of the photovoltaic with battery energy storage system (PV-BESS) from the

Battery energy-storage system: A review of technologies,

Oct 1, 2021 · This paper provides a comprehensive review of the battery energy-storage system concerning optimal sizing objectives, the system constraint, various optimization models, and

An Overview of Batteries for Photovoltaic (PV) Systems

Jan 31, 2024 · If the lifetime of the battery is less than 3.5 years then battery is the highest cost incurring component in the system. The battery units are not ideal. There may be energy

Power control strategy of a photovoltaic system with battery storage system

Dec 21, 2022 · The research presented in this paper provides an important contribution to the application of fuzzy theory to improve the power and performance of a hybrid system

Battery storage efficiency: How to gauge long

Jul 26, 2024 · Discover the key considerations for efficient home battery storage systems: system efficiency, battery efficiency, and optimal battery storage size

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

A review of photovoltaic systems size optimization techniques

Jun 1, 2013 · PV system size and performance strongly depend on metrological variables such as solar energy, wind speed and ambient temperature and therefore, to optimize a PV system,

Battery capacity design and optimal operation control of photovoltaic

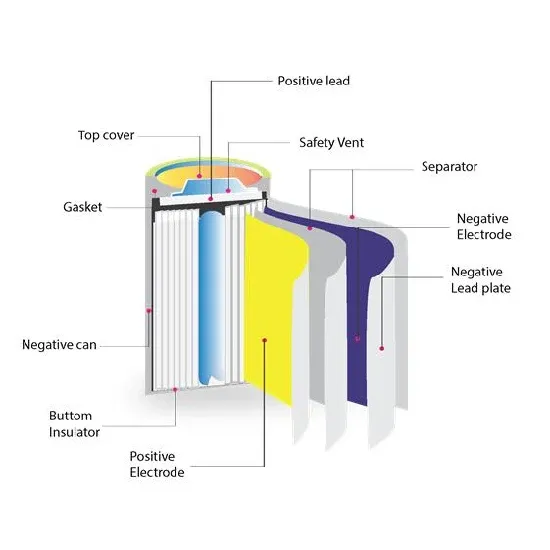

Feb 15, 2024 · To simulate the real-life battery precisely, researchers came up with three major lithium-ion battery models [18], i.e. black box models with multiple artificial models, grey box

A novel holistic metric for sustainability assessment of photovoltaic

Aug 16, 2025 · The findings contribute to a more comprehensive approach for evaluating and improving the resilience of PV-battery systems, addressing gaps in conventional sustainability

5MWh Containerized Energy Storage System

The fire protection system can penetrate into each battery module to ensure the safety of the entire cabinet and minimize the damage in case of fire. Product features(Containerized

Containerized Battery Energy Storage Systems (BESS)

Our''s Containerized Battery Energy Storage Systems (BESS) offer a streamlined, modular approach to energy storage. Packaged in ISO-certified containers, our Containerized BESS

Battery Energy Storage System Evaluation Method

Jan 30, 2024 · This report describes development of an effort to assess Battery Energy Storage System (BESS) performance that the U.S. Department of Energy (DOE) Federal Energy

6 FAQs about [How to know the battery life of photovoltaic container system]

How to optimize battery energy storage systems?

Optimizing Battery Energy Storage Systems (BESS) requires careful consideration of key performance indicators. Capacity, voltage, C-rate, DOD, SOC, SOH, energy density, power density, and cycle life collectively impact efficiency, reliability, and cost-effectiveness.

What is a battery energy storage system (BESS)?

As the demand for renewable energy and grid stability grows, Battery Energy Storage Systems (BESS) play a vital role in enhancing energy efficiency and reliability. Evaluating key performance indicators (KPIs) is essential for optimizing energy storage solutions.

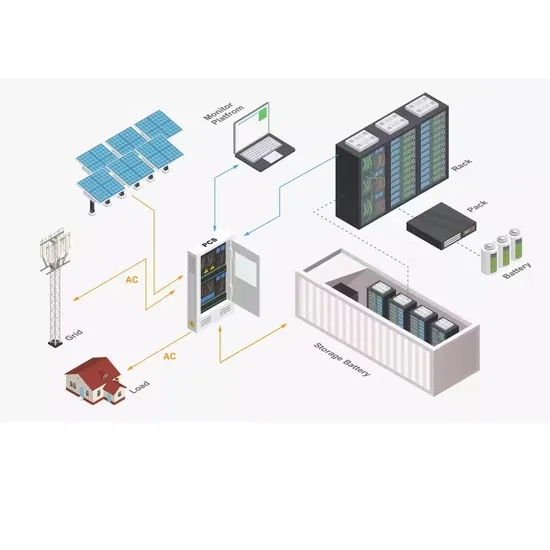

What are the components of a photovoltaic system?

The system includes a 10 kWp multicrystalline-silicon photovoltaic (PV) system (solar irradiation about 1350 kWh/m 2 /year and annual yield 1000 kWh/kWp), an iron phosphate lithium-ion (LiFePO 4) battery, and other components such as the control system, battery housing, and two inverters (one for the PV system and one for the battery system).

How is metered PV energy delivery compared to a computer model?

That method compared actual metered PV system energy delivery with that of a computer model. The computer model used was the National Renewable Energy Laboratory’s (NREL’s) System Advisor Model (SAM). The KPIs reported are Availability (% up-time) and Performance Ratio (PR).

Why is stable voltage important in energy storage systems?

Stable voltage output is critical in energy storage systems to prevent damage to connected equipment. If the voltage fluctuates significantly, electronic components may fail, affecting the reliability of power supply in applications such as microgrids and industrial backup power. 3. Charge-Discharge Rate (C-Rate): Performance and Response Time

What is the maximum energy accumulated in a battery?

The maximum amount of energy accumulated in the battery within the analysis period is the Demonstrated Capacity (kWh or MWh of storage exercised). In order to normalize and interpret results, Efficiency can be compared to rated efficiency and Demonstrated Capacity can be divided by rated capacity for a normalized Capacity Ratio.

Learn More

- How much does it cost to replace the battery cabinet for photovoltaic communication

- How big a battery can a 10 watt photovoltaic panel allow

- How is the photovoltaic container factory

- Container photovoltaic energy storage lithium battery solution

- How big is the battery for a 10w photovoltaic solar panel

- How to view batteries in photovoltaic container systems

- What is the capacity of the container photovoltaic energy storage battery warehouse

- How many photovoltaic panels are needed for a 200ah battery

- How big a lead-acid battery should I use for a 100W photovoltaic panel

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.