Flywheel-lithium battery hybrid energy storage

Sep 2, 2020 · A hybrid energy storage system combining lithium-ion batteries with mechanical energy storage in the form of flywheels has gone into operation in

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · An early unit from the project, an M25 with a power capacity of 6.25kW and 25kWh energy storage capacity flywheel, was temporarily sent to a site in Subic Bay Philippines by

South Sudan Flywheel Energy Storage Project

A public-private partnership in South Sudan has launched the country''''s first major solar power plant and Battery Energy Storage System (BESS) in the capital Juba, where it is expected to

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

South sudan energy storage power station news

About 130 MW of South Sudan''''s installed power capacity will be operational by 2025, a portion of which will be used to power the nation''''s numerous oil fields. The SSEC''''s Image: Shenzen

Flywheel energy and power storage systems

Feb 1, 2007 · During that time several shapes and designs where implemented, but it took until the early 20th century before flywheel rotor shapes and rotational stress were thoroughly

Flywheels for ElectraNet substation

Nov 22, 2021 · Grids like this lack the inertia of heavy power turbines that can instantaneously bridge sudden frequency drops. So, to avert the risk of blackouts, Australian grid operator

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

South Sudan Flywheel Energy Storage Market (2025-2031)

South Sudan Flywheel Energy Storage Market (2025-2031) | Companies, Share, Analysis, Value, Forecast, Outlook, Growth, Industry, Trends, Competitive Landscape, Size & Revenue,

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Flywheel Energy Storage Systems and their Applications: A

Aug 16, 2025 · Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational

A Review of Flywheel Energy Storage System Technologies

Sep 7, 2023 · Using energy storage technology can improve the stability and quality of the power grid. One such technology is flywheel energy storage systems (FESSs).

South Sudan Offshore Energy Storage Market (2025-2031)

Market Forecast By Type (Lithium-Ion Batteries, Hydrogen Storage, Flywheel Energy Storage, Compressed Air Energy Storage), By Application Area (Wind Energy Storage, Offshore

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

6 FAQs about [Flywheel Energy Storage in South Sudan]

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is a solar power plant in South Sudan?

Image: The recently launched 20MW solar energy plant in South Sudan. Credit: Ezra Group A public-private partnership in South Sudan has launched the country’s first major solar power plant and Battery Energy Storage System (BESS) in the capital Juba, where it is expected to provide electricity to thousands of homes.

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

How do fly wheels store energy?

Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. Energy storage is a vital component of any power system, as the stored energy can be used to offset inconsistencies in the power delivery system.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

Learn More

- South Sudan Power Plant Energy Storage Equipment Manufacturer

- South Sudan grid-connected energy storage system export

- Energy storage battery companies in South Sudan

- Flywheel energy storage power station configuration

- New Energy Power Station Energy Storage Flywheel

- How much does a mobile energy storage cabin cost in South America

- Sudan large energy storage cabinet supplier

- South Africa s future gravity energy storage system

- How much flywheel energy storage is there in Cameroon communication base stations

Industrial & Commercial Energy Storage Market Growth

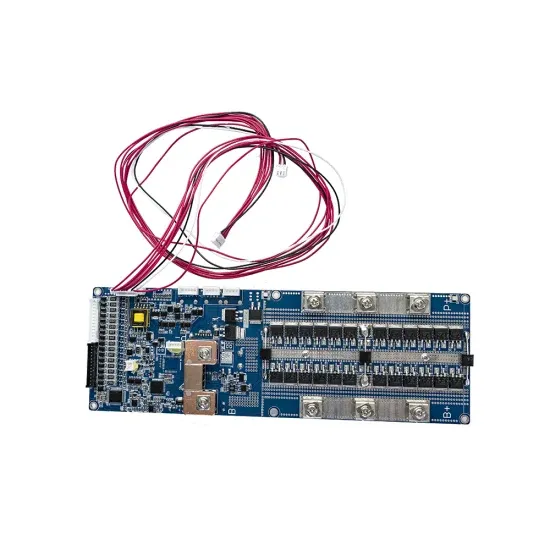

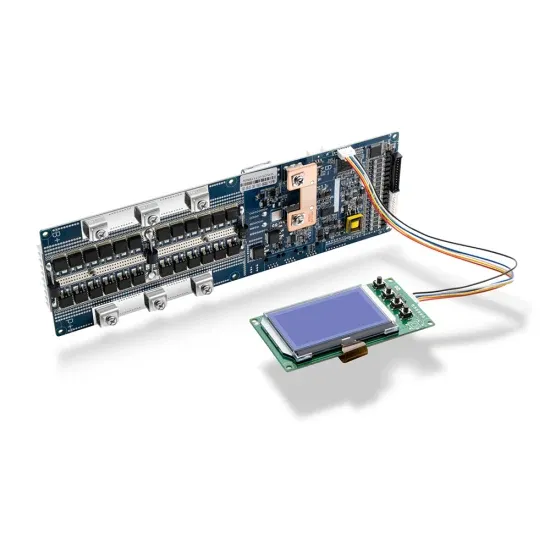

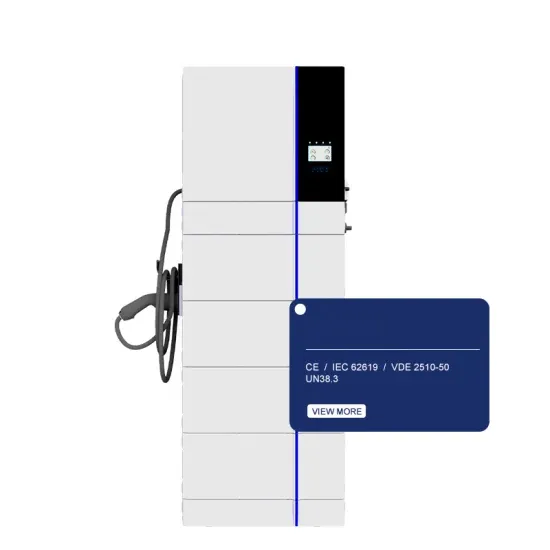

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.