PV inverter with decoupled active and reactive power control

Dec 1, 2020 · The inverters reduce the losses because of fewer switches, but control implementation is difficult as the inverter stage handles both MPPT tracking and output power

Dual-sided Cooling for Automotive Inverters

May 20, 2015 · The main challenges faced by designers of automotive traction inverters are cost, size and weight reduction. This paper presents a practical implementation of dual-sided

Analysis, Design and Implementation of Phase-Locked-Loop

Oct 11, 2019 · Outline Introduction Grid-Connected Inverters Phase-Locked-Loop for grid-connected converters Different PLL schemes Simulation Results Implementation in Digital

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

DESIGN AND IMPLEMENTATION OF 1 KVA INVERTER WITH SOLAR POWER

PDF | On Jun 2, 2024, A. P. Kereza and others published DESIGN AND IMPLEMENTATION OF 1 KVA INVERTER WITH SOLAR POWER | Find, read and cite all the research you need on

Next generation power inverter for grid resilience:

Nov 15, 2024 · Because the majority of renewable energy sources provide DC power, power electronic inverters are necessary for their conversion from DC to AC power. To fulfill this

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The requirements for the grid-connected inverter include; low total harmonic distortion of the currents injected into the grid, maximum power point tracking, high efficiency,

3-Level GaN Inverters for Highly Efficient Power Electronics

Feb 14, 2025 · Multi-level inverters, especially 3-level configurations, are becoming crucial in electric vehicle drivetrains for their efficiency and capability to handle high voltage levels. Hofer

Impact of IEEE 1547 Standard on Smart Inverters and the

Apr 29, 2025 · This white paper presents smart inverter features along with the implementation challenges and potential solutions. The paper starts with an introduction to smart inverter

Inverter Integration & Implementation Guide

May 8, 2025 · The first parameters used to help make an inverter choice include the motor''s number of phases, DC system voltage, and motor phase currents required to produce the

FULL BRIDGE TOPOLOGY SINGLE PHASE INVERTER

Oct 16, 2021 · In the implementation of solar power plants, inverters are usually used to run AC current equipment in the house or building. To perform its function, the inverter gets a direct

Design, Implementation, and Performance Analysis of a High

Jun 13, 2025 · This paper introduces a single-stage solar inverter design that seamlessly integrates battery-based energy storage for both on-grid and off-grid scenarios. The

DC-Link Zero Power Fluctuation of Grid-Tied Inverters: Implementation

Aug 28, 2024 · Unbalanced grid conditions caused by asymmetrical faults or voltage distortions extremely deteriorate the grid reliability, resulting in power fluctuation of three-phase grid-tied

Design and Implementation of a Three Phase Inverter for

Dec 1, 2016 · This objective can be realized most successfully and appropriately if the microgrid acts as controllable voltage source. [2]- [3] The project proposed hereby aims to work on

Design of Multi-Level Inverter for Power Electronics

Dec 19, 2023 · The proposed research work aims to explore the concept and implementation of a five-level inverter, providing detailed analysis of its working principle, advantages, applications,

6 FAQs about [Inverter implementation power]

What is a power inverter?

A power inverter, or inverter, is an electronic device or circuitry that changes direct current (DC) into alternating current (AC). Depending upon the number of phases of the AC output, there are several types of inverters. DC is the unidirectional flow of electric charge.

How do I create a single-phase inverter?

Plug the GreenPAK Development Kit to your computer and hit program to create the single-phase inverter. A power inverter, or inverter, is an electronic device or circuitry that changes direct current (DC) into alternating current (AC). Depending upon the number of phases of the AC output, there are several types of inverters.

How to maximize the output voltage of an inverter?

To maximize the output voltage, the fundamental component of the input voltage on each branch must be 180o out of phase. The semiconductors of each branch are complementary in performance, which is to say when one is conducting the other is cut-off and vice versa. This topology is the most widely used for inverters.

How does a DC inverter work?

The DC voltages are fed from the battery and the output obtained from the inverter can be used to supply the AC load. For the purpose of this application note the AC frequency has been set to 50Hz, a common household power frequency in many parts of the world. Correspondingly, the period is 20ms.

What are the different types of inverters?

In order to transfer electrical power with different current profiles, special devices are required. Devices that convert AC into DC are known as rectifiers and devices that convert DC into AC are known as inverters. There are two main topologies of single-phase inverters; half-bridge and full-bridge topologies.

How to invert low voltage DC power?

The method, in which the low voltage DC power is inverted, is completed in two steps. The first step is the conversion of the low voltage DC power to a high voltage DC source, and the second step is the conversion of the high DC source to an AC waveform using pulse width modulation.

Learn More

- 10000w power inverter factory in Mauritania

- North Macedonia power frequency isolation 150kw inverter

- Outdoor rainproof power supply modified inverter

- 12v inverter booster power supply

- Congo low power inverter price

- Conakry inverter power

- Photovoltaic power inverter anti-reverse flow

- Wholesale 200w power inverter in Russia

- Power frequency pure sine wave inverter 2

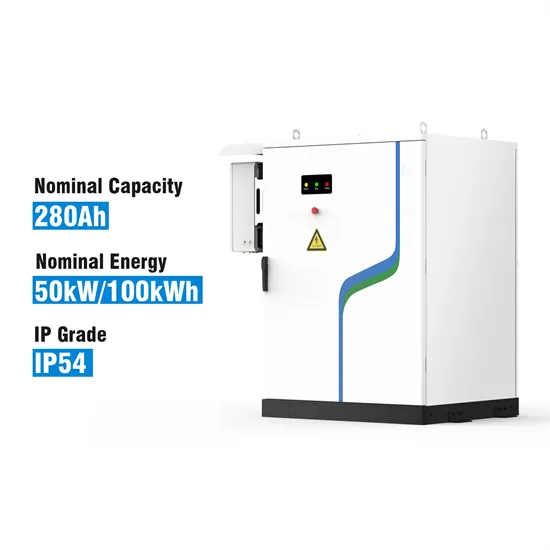

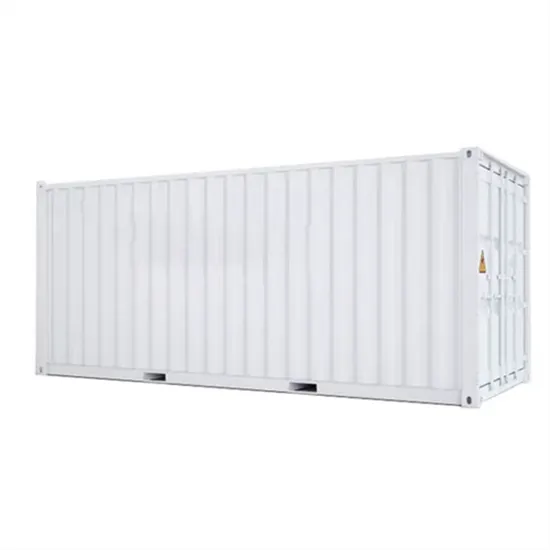

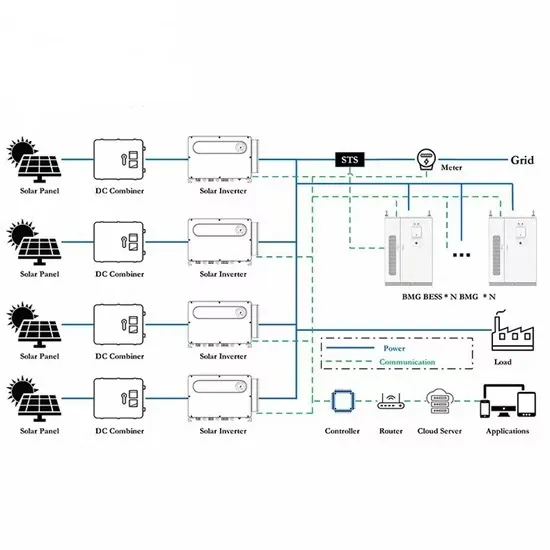

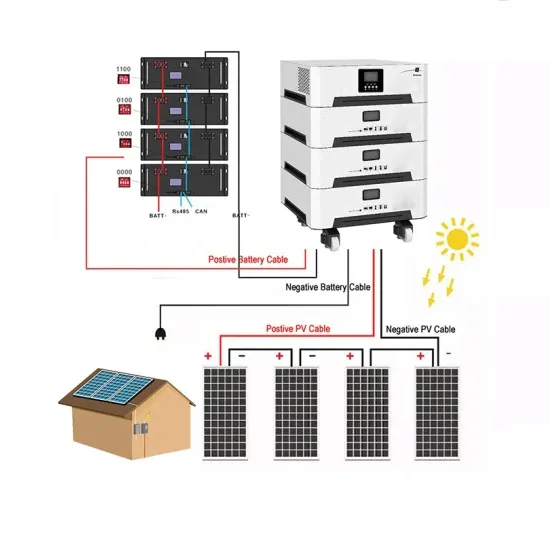

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.