Inverter Usage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · The Inverter Usage Calculator helps users to determine the energy consumption of their inverter systems, which is crucial for managing electricity bills and assessing power needs.

Inverter Amps: The Ultimate Guide to Understanding Power Consumption

Jan 29, 2025 · When it comes to powering your devices on the go, inverters are an excellent solution. However, it''s essential to understand how much power they consume to ensure safe

Power Inverter Calculator | Watt Calculator | Go Power!

4 days ago · Which power inverter is right for you? By answering these simple questions, we can recommend a product for you in just a few moments. This calculator helps us identify how

400 Watt Inverter Uses: What It Powers & Why It''s Worth It

Jun 6, 2025 · Discover the power and versatility of a 400 watt inverter—compact, efficient, and perfect for camping, RVs, or emergency backup to run your essential devices reliably.

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages. First stage is high frequency DC to DC

Understanding the Power Consumption of Inverter

Watts (W) are a unit of power representing the rate of energy consumption. The wattage of an inverter refrigerator can vary depending on several factors, including model, size, and usage.

How Many Watts Does an Inverter Refrigerator Use: A Closer

May 28, 2024 · An inverter refrigerator is a popular appliance that helps us keep our food fresh and cool. However, one question that often arises is, "How many watts does an inverter

Unveiled! the truth about inverter acs: how many watts do

Aug 30, 2024 · This modulation allows for significant energy savings and improved efficiency. Factors Affecting Power Consumption The power consumption of an inverter air conditioner

Inverter Energy Calculator, Formula, Inverter Energy Calculation

4 days ago · Inverter Energy Calculator: Enter the values of Inverter Power Consumption PI (W) & Total Time of usage T (min) to determine the value of Inverter Energy IE (J).

Inverter Size Calculator [Power Inverter, AC, DC,

Feb 7, 2025 · Calculate the ideal inverter size with the Inverter Size Calculator. Perfect for selecting inverters for homes, solar panels, or vehicles based on

Inverter Power Draw: How Much Power Does an Inverter Use

Mar 17, 2025 · An inverter draws power from a battery depending on its efficiency, typically over 92%. For a connected load of 250 watts, the inverter uses less than 270 watts from the

What Can a 600W Inverter Run? The Ultimate Guide to 600 Watt Inverters

Jun 9, 2025 · Discover what a 600w inverter can run, from laptops to small appliances. Learn usage tips, battery needs, and best practices for off-grid or backup power.

Frequently Asked Questions about Inverters

The efficiency of modern inverters is more than 92 %. This means that a maximum of 8 % of the power consumption is used to convert battery voltage to 230V/50Hz. A connected load of 250

Understanding Inverter Power Consumption: Do Inverters Use Power

Mar 12, 2025 · In today''s energy-conscious world, many homeowners and businesses are increasingly turning to energy-efficient solutions, and inverters have become an essential part

Inverter Energy Calculator, Formula, Inverter Energy Calculation

4 days ago · The Inverter Energy IE (J) in Joules is equal to the Inverter Power Consumption PI (W) in Watts and multiply to the Total Time of Usage T (min) in minute and again multiply by 60.

What Is The Energy Consumption Of A Solar Inverter?

Mar 30, 2025 · A solar inverter is a converter that converts or inverts the direct current (DC) energy produced by a solar panel, making it possible to power your home with solar energy.

How Much Power Does An Inverter Draw With No Load?

Input the power your inverter consumes in watts. This value can typically be found in the inverter''s specification sheet. Input how long the inverter has been or will be running in minutes. The tool

6 FAQs about [12v1700 watt inverter power consumption]

How much power does a 12 volt inverter use?

Power conversion losses from converting 12v DC battery power to 230v AC mains power in an inverter uses about 10% more power than the actual appliance draws, so expect around a 1540w draw from the battery (1400w x 1.1 = 1540w). Assuming a cup of coffee takes about a minute to make: 1540w / 12 volts = 128 Amps

How much power does an inverter use?

But this amount may vary depending on the type of battery bank used and the types of loads connected to the inverter. Typically, in a no-load current, the energy drawn by the inverter is only 2 to 10 watts an hour. What Amount of Power is Wasted by Inverter? Do not confuse the inverter’s no-load current with the efficiency rating of the inverter.

How much power does a 500W inverter use?

The inverter itself uses about 30W running a 500W load. There are some times that there is no load. Does the inverter still consume the same amount of power then? Or significantly less because it is proportional to the load? It's hard to tell since my usage watt meters are downstream after the inverter. Thanks in advance.

How does the inverter energy calculator work?

Energy is calculated in joules, based on the power consumption (in watts) and duration of usage (in minutes). This calculation helps homeowners, solar energy users, electricians, and technicians better understand energy needs and optimize battery and power configurations. Using the Inverter Energy Calculator is very simple.

How many watts in a 24V inverter?

Power drawn = 24V * 0.4 = 9.6 watts This formula and calculation are applicable to all inverters irrespective of their size. 12V or 24V is the only thing that will make the difference in the power consumed. Remember, the higher the voltage is the greater the no-load current will be.

How many Watts Does a 10 watt inverter use?

For example, sometimes a radio connected to the inverter uses just 5 watts but the inverter itself consumes 10 watts. This is a complete waste of money and energy. Secondly, accumulation of no current load like imagine your inverter is left on 24 by 7. Now, with a 10-watt no-power draw rating, it is almost 70 watts per week that will be wasted.

Learn More

- China 500 watt power inverter in El-Salvador

- China 500 watt power inverter in Los-Angeles

- China 500 watt power inverter in Denmark

- China 500 watt power inverter in Kuala-Lumpur

- How much power does a 1 300 watt inverter have

- 1kW high frequency inverter power consumption

- Inverter conversion for photovoltaic power generation

- Photovoltaic power station inverter in the Democratic Republic of Congo

- What is the power consumption mode of 5g base station

Industrial & Commercial Energy Storage Market Growth

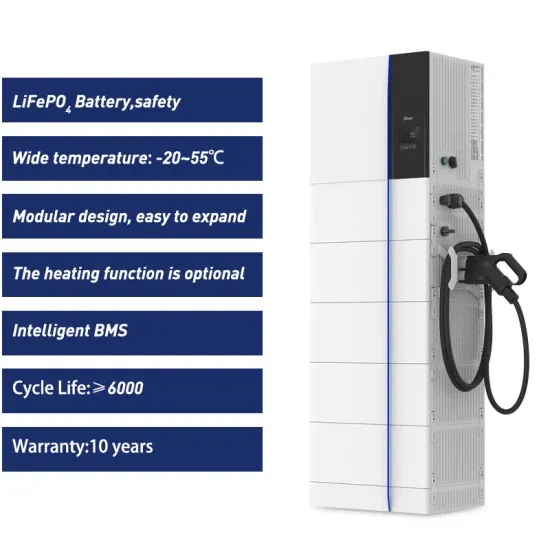

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.