Battery Energy Storage System Installation requirements

Mar 16, 2021 · This standard places restrictions on where a battery energy storage system (BESS) can be located and places restrictions on other equipment located in close proximity to

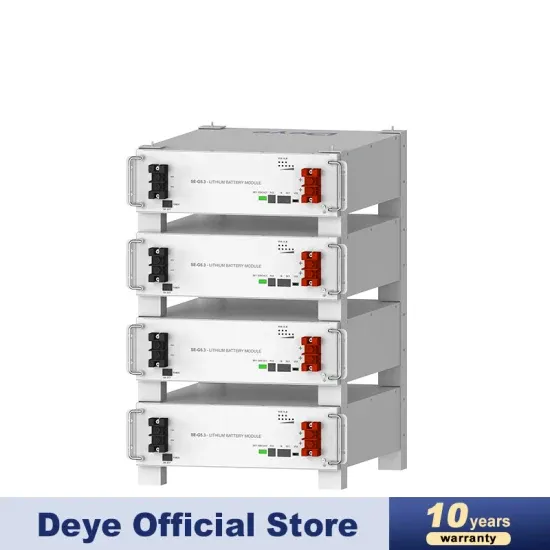

Battery cabinet design standards and specifications

What is a battery cabinet? A battery cabinet serves as a protective and organized enclosure for housing multiple battery modules within an energy storage system. Its primary purpose is to

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Procedure Refer to Figure 3 and install the 19" or 23" relay rack mounting angles to the battery cabinet. Mounting hardware is provided with the battery cabinet. Torque these

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Guidelines for storage & usAGE of lead acid batteries

May 19, 2022 · 1 Battery Overview There are primarily three kinds of batteries used in UPSs—vented lead acid (VLA) (also called flooded-cell),valve-regulated lead-acid (VRLA),

A Guide To UPS Room Layout | Carter Sullivan

May 4, 2020 · We explore the fundamentals of UPS room layout and the things you need to consider when deciding where to locate your essential power protection systems.

A Comprehensive Roadmap for Successful Battery Energy

Jun 10, 2025 · A Roadmap for Battery Energy Storage System Execution — ### Introduction The integration of energy storage products commences at the cell level, with manufacturers

Are the layout requirements of the energy storage server

What type of batteries are used in energy storage cabinets? Lithium batterieshave become the most commonly used battery type in modern energy storage cabinets due to their high energy

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · There may be multiple ways to configure the cabinet, so consider all possible options. For instance, if a battery, rack and charger are required the system can be designed

Technical requirements for cabinet battery compartment

Battery Contact Considerations o Dimensional: ANSI and IEC industry standard dimensions should be used when designing a battery compartment to avoid battery fit problems. o

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Install battery retention strap through openings in rear of battery cabinet. Orient the buckle per Figure 17. Figure 4: Connectors and Wires Moved to the Side Install the separately

6 FAQs about [Battery cabinet layout requirements and standards]

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What are the requirements for a battery layout?

The layout should accommodate: 2. Structural Requirements Floor loading capacity is critical - industrial batteries typically weigh 1500-3000 kg/m². For VLA (flooded) batteries, acid-resistant floor coatings compliant with AS/NZS 2430.3.2 are required.

What is a standard in battery testing?

In layman's terms, a standard provides minimum requirements and/or instructions in agreement within the industry for common reference. Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE).

What factors should be considered when designing a battery room floor?

Several factors need to be considered when designing a battery room floor. For VRLA batteries the simplest of protection is normally acceptable but rooms housing vented battery types need to be impermeable for battery acid or alkaline for nickel cadmium types.

Does a battery rack need to be NEBS certified?

Even if a company installs a NEBS-certified battery rack in a site, the building inspector can still require the rack to be certified to IBC or any other building code that city or state has adopted. Which seismic code or standard is the best fit?

Learn More

- DC battery cabinet grounding requirements and standards

- Energy storage cabinet installation requirements and standards

- Outdoor battery cabinet design requirements

- Installation specification requirements of battery cabinet in computer room

- New Energy Battery Cabinet Test Standards

- Battery Module Battery Cabinet

- Costa Rica outdoor communication battery cabinet customized integrated system

- Battery cabinet price latest

- ASEAN battery cabinet platform system

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

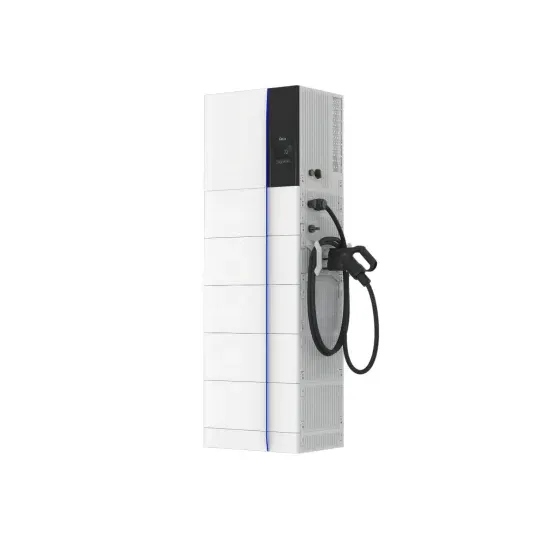

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.