Design and Analysis of a composite Flywheel for Energy

Oct 21, 2024 · While metallic flywheels offer good strength, their significant mass limits the energy storage capacity per unit weight, making them less suitable for applications requiring high

High-Speed Kinetic Energy Storage System Development

Apr 8, 2025 · Flywheel energy storage systems (FESSs) can reach much higher speeds with the development of technology. This is possible with the development of composite materials. In

Flywheel Energy Storage System Basics

Aug 13, 2025 · However on the downside, flywheel energy storage systems have low energy storage density per unit of weight and volume. Beacon Power operates a 25 kilowatt / 100

Review of Flywheel Energy Storage Systems structures and applications

Mar 1, 2017 · Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

Enhancing vehicular performance with flywheel energy storage systems

Dec 10, 2024 · Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheels store rotational kinetic energy in the form of a spinning cylinder or disc, then use this stored kinetic energy to regenerate electricity at a later time. The amount of

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Critical Review of Flywheel Energy Storage System

Apr 13, 2021 · This review presents a detailed summary of the latest technologies used in flywheel energy storage systems (FESS). This paper covers the types

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · The core element of a flywheel consists of a rotating mass, typically axisymmetric, which stores rotary kinetic energy E according to (Equation 1) E = 1 2 I ω 2 [J], where E is the

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · The lithium-ion battery has a high energy density, lower cost per energy capacity but much less power density, and high cost per power capacity. This explains its popularity in

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

Flywheel energy and power storage systems

Feb 1, 2007 · Small-scale flywheel energy storage systems have relatively low specific energy figures once volume and weight of containment is comprised. But the high specific power

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheel Energy Storage (FES) system is an electromechanical storage system in which energy is stored in the kinetic energy of a rotating mass. Flywheel systems are

A Comprehensive Review on Flywheel Energy Storage Systems

Aug 2, 2023 · Finding efficient and satisfactory energy storage systems (ESSs) is one of the main concerns in the industry. Flywheel energy storage system (FESS) is one of the most

Design and Analysis of a composite Flywheel for Energy

Oct 21, 2024 · One such promising technology is the flywheel energy storage system (FESS), which offers the ability to store kinetic energy in a rotating mass, providing high power density,

What is the energy storage capacity density of a flywheel?

May 21, 2024 · The energy storage density, expressed in watt-hours per kilogram (Wh/kg), is a vital metric for assessing how efficiently a flywheel can store energy relative to its weight.

A review of flywheel energy storage systems:

Mar 8, 2021 · We also highlighted the opportunities and potential directions for the future development of FESS technologies. A overview of system components

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

6 FAQs about [Weight of flywheel energy storage system]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

Are flywheel energy storages commercially available?

Flywheel energy storages are commercially available (TRL 9) but have not yet experienced large-scale commercialisation due to their cost disadvantages in comparison with battery storages (higher investment, lower energy density). Another challenge is the comparably high standby loss in FESS caused by the magnetic drag of the motor-generator.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Why are high-strength steel flywheels a good choice?

High-strength steel flywheels have a high energy density (volume-based energy) due to their high mass density. Furthermore, they are superior to composite ones regarding thermal conductivity and design data availability, such as SN curves and fracture toughness.

Learn More

- Weight of flywheel energy storage system

- Weight of energy storage battery

- Production of energy storage flywheel

- One has several communication base stations with flywheel energy storage

- Space Station Flywheel Energy Storage

- Maximum flywheel energy storage

- Flywheel energy storage disc material

- Libya flywheel energy storage system

- Flywheel energy storage battery self-discharge rate

Industrial & Commercial Energy Storage Market Growth

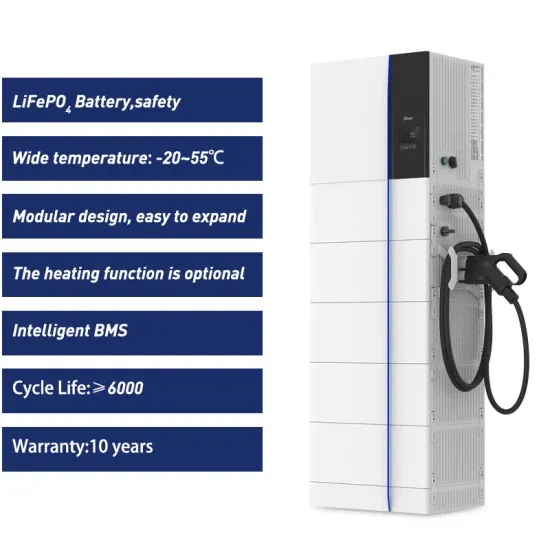

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.