Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

self-discharge of flywheel energy storage

Energies | Free Full-Text | Emissions Effects of Energy Storage for Frequency Regulation: Comparing Battery and Flywheel Storage The self-discharge rate of 1.145% per hour was

Experimental Techniques for Flywheel Energy Storage System Self

Jul 26, 2024 · In this paper, an experimental characterisation technique for Flywheel Energy Storage Systems (FESS) behaviour in self-discharge phase is presented. The self-discharge

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · The lithium-ion battery has a high energy density, lower cost per energy capacity but much less power density, and high cost per power capacity. This explains its popularity in

Flywheel Energy Storage Study

May 4, 2020 · The FES System operator was instructed to charge the flywheel from minimum to maximum speed at full power and then discharge back down to the minimum speed at a lower

(PDF) Critical Review of Flywheel Energy Storage

Apr 13, 2021 · Different types of machines for flywheel energy storage systems are also discussed. This serves to analyse which implementations reduce the

A mechanical analysis of a flywheel as an energy storage

Aug 27, 2021 · There are several di erent parameters to consider when designing a ywheel system to optimise its energy storage capabilities in terms of its speci c energy, generated

Power Management of Hybrid Flywheel-Battery Energy Storage

Feb 26, 2025 · A flywheel and lithium-ion battery''s complementary power and energy characteristics offer grid services with an enhanced power response, energy capacity, and cy

What is the self-discharge rate of flywheel energy storage

Flywheel energy storage systems: A critical review on A thorough comparative study based on energy density, specific power, efficiency lifespan, life-cycle, self-discharge rates, cost of

Kinetic Energy Storage (Flywheels)

Kinetic Energy Storage (Flywheels) Principle kinetic energy storage system is composed simply by a flywheel driven by an electrical machine (different types of technologies are considered,

A comprehensive review of stationary energy storage

May 1, 2022 · The comprehensive review shows that, from the electrochemical storage category, the lithium-ion battery fits both low and medium-size applications with high power and energy

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · Comparing to batteries, both flywheel and super-capacitor have high power density and lower cost per power capacity. The drawback of supercapacitors is that it has a narrower

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

What is the self-discharge rate of flywheel energy storage

Development and prospect of flywheel energy storage However, despite the advantages of FESS, some drawbacks include their high self-discharging rate, and safety issues [18].Some

Overview of Flywheel Systems for Renewable Energy

Jul 12, 2024 · son in terms of specific power, specific energy, cycle life, self-discharge rate and efficiency can be found, for example, in [3]. Compared with other energy storage methods,

Development and prospect of flywheel energy storage

Oct 1, 2023 · Some of the solutions to these limitations suggested in literature include the improving the bearing for decreasing the self-discharge rate, reducing the efficiency of low

Flywheel energy storage self-discharge

How does Flywheel energy storage differ from other energy storage methods? son in terms of specific power, specific energy, cycle life, self-discharge rate and efficiency can be found, for

Development and Optimization of Hybrid Flywheel

May 29, 2025 · For instance, flywheels can quickly compensate for sudden power shortages or demand spikes, while batteries provide long-term energy storage. Data indicates that HESS

Analysis of Standby Losses and Charging Cycles in Flywheel

Aug 27, 2020 · The standby self-discharge rate of the flywheel system at three different pressures of 0.01, 0.1 and 1 Pa is shown in Figure 9. The flywheel is considered to be initially fully

Flywheel Energy Storage Systems: A Critical Review on

Nov 15, 2021 · However, being one of the oldest ESS, the fly- wheel ESS (FESS) has acquired the tendency to raise itself among others being eco-friendly and storing energy up to

Flywheel Energy Storage System

Flywheel energy storage system is an energy storage device that converts mechanical energy into electrical energy, breaking through the limitations of chemical batteries and achieving energy

6 FAQs about [Flywheel energy storage battery self-discharge rate]

How does Flywheel energy storage differ from other energy storage methods?

son in terms of specific power, specific energy, cycle life, self-discharge rate and efficiency can be found, for example, in . Compared with other energy storage methods, notably chemical batteries, the flywheel energy storage has much higher power densit

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

What is the future of Flywheel energy storage systems?

The future of flywheel energy storage systems is debatable mainly because its success hinges on several factors. The amount of research and funding put into mechanical batteries, such as the FESS over chemical batteries, will determine the development of this technology.

What is flywheel energy storage system (fess)?

but lower energy density, longer life cycles and comparable efficiency, which is mostly attractive for short-term energy storage.Flywheel energy storage systems (FESS) have been used in uninterrupted power supply (UPS) –, brake energy recovery for ra

Can flywheels be used for power storage systems?

Flywheels are now a possible technology for power storage systems for fixed or mobile installations. FESS have numerous advantages, such as high power density, high energy density, no capacity degradation, ease of measurement of state of charge, don’t require periodic maintenance and have short recharge times .

Learn More

- What is flywheel battery energy storage

- The discharge rate of energy storage battery is 1p

- Vanadium battery energy storage capacity

- Banjul lithium battery hybrid energy storage project

- Supercapacitor flywheel energy storage

- Austrian photovoltaic energy storage battery manufacturer

- Swiss Photovoltaic Energy Storage Cabinet Battery Lithium Battery

- Baku vanadium battery energy storage commercialization

- Huawei Energy Storage Battery Speed Chain

Industrial & Commercial Energy Storage Market Growth

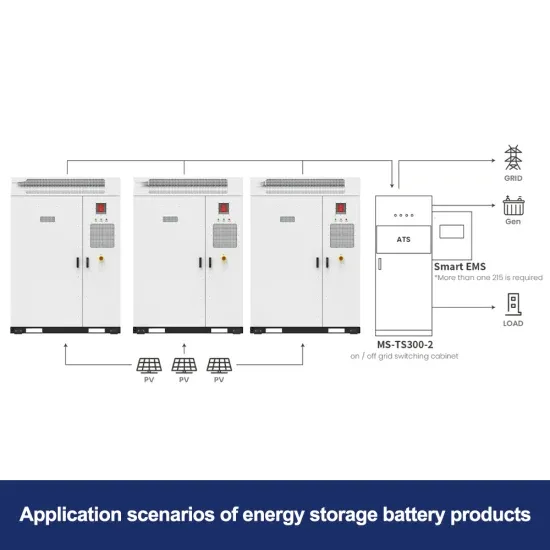

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.