Efficiency of Inverter: Calculation & Equation Guide

Jun 22, 2022 · This power inverter efficiency number varies with inverter load power capacity, as efficiency rises and may reach its maximum value at higher load power capacity compared to

Efficiency of Inverter: Calculation & Equation

Mar 4, 2023 · This power inverter efficiency number varies with inverter load power capacity, as efficiency rises and may reach its maximum value at higher

The Only Inverter Size Chart You''ll Ever Need

Sep 25, 2023 · During our research, we discovered that most inverters range in size from 300 watts up to over 3000 watts. In this article, we guide you through the different inverter sizes.

How to Calculate Inverter Capacity for Grid-Tied

Nov 6, 2024 · The capacity of the inverter directly impacts the efficiency, performance, and safety of the system. This article will walk you through the

The Efficiency of Solar Inverters-

Mar 3, 2021 · In calculating CEC and Euro efficiency, instead of looking only at how efficiently the inverter functions at its power input ''sweet spot'', calculating weighted efficiency requires first

Find the Right Inverter Size: How Big An Inverter Do You need?

Dec 31, 2024 · When it comes to powering your devices through an inverter, one of the most critical aspects to consider is size—how big an inverter do you need? Whether you''re on an

Solar Inverter Sizing Calculator: Important Guide

Nov 18, 2024 · When designing a solar power system, selecting the right inverter is crucial. An incorrectly sized solar inverter can lead to inefficiency, wasted

How To Calculate An Inverter Capacity Correctly

Jan 27, 2025 · Calculating the inverter capacity requires assessing the power output of your solar panels, your energy needs, and other relevant factors. Here''s a step-by-step process to

CSM_Inverter_Selection_TG_E_2_1

Oct 23, 2012 · When the required braking resistance is less than the minimum connectable resistance, change the inverter or regenerative energy braking to the one having a larger

How to calculate inverter and battery capacity?

May 16, 2022 · When more power starts coming and going, we plan to install an inverter battery, but it is a bit difficult to calculate how many kW of the inverter

How to Calculate the Maximum Output Power of a Power Inverter

Just make sure the power inverter is rated for the power (in watts) for the amount of power that you are looking to use. So basically now you know the amount of power that can be drawn

Power Inverters: What Are They & How Do They

Dec 17, 2019 · An inverter (or power inverter) is defined as a power electronics device that converts DC voltage into AC voltage. While DC power is common

What Size Inverter Do I Need for My Power Needs

Dec 13, 2023 · 5. The size of the inverter you need depends on the total power consumption of the devices you want to run simultaneously. As a general rule of thumb, multiply the total

Inverter Capacity Calculator

Mar 31, 2025 · Inverter Capacity: The maximum load an inverter can handle, measured in watts (W). Power Requirement: The amount of electrical power needed by a device to operate

6 FAQs about [What is the general power capacity of the inverter ]

What is inverter capacity?

Inverter capacity, measured in watts (W) or kilowatts (kW), refers to the power an inverter can continuously supply. To determine the right capacity, consider the total wattage of the devices you'll connect to the inverter. Add up the wattage of all appliances and devices. As a general guideline: There are several main types of inverters:

How to choose the capacity of an inverter?

The capacity of an inverter should be chosen based on the total power requirement of the devices it will be powering. If the total power requirement exceeds the inverter’s capacity, it may fail or damage the connected devices.

Why is inverter capacity important?

By understanding the required inverter capacity, users can ensure that their electrical devices are powered efficiently and avoid overloading the system. Inverters have been crucial in providing backup power, particularly in regions with unreliable electricity supply.

How much power does an inverter need?

It’s important to note what this means: In order for an inverter to put out the rated amount of power, it will need to have a power input that exceeds the output. For example, an inverter with a rated output power of 5,000 W and a peak efficiency of 95% requires an input power of 5,263 W to operate at full power.

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

Do I need a larger inverter?

Simultaneous use: If you plan to run multiple high-wattage appliances concurrently, you'll need a larger capacity. Surge power: Account for the higher initial power draw of appliances like refrigerators and air conditioners. Your inverter must handle these surges without overloading.

Learn More

- What is the energy storage of wind power in general

- What is the best power for a 12v inverter

- What is the power of a general photovoltaic power station generator

- What is the best voltage for a power frequency inverter

- What is the maximum power of a 12v high power inverter

- Small power industrial inverter

- Middle East Power Inverter Structure Manufacturer

- What are the functions of power storage vehicles

- Niue Solar Power Inverter

Industrial & Commercial Energy Storage Market Growth

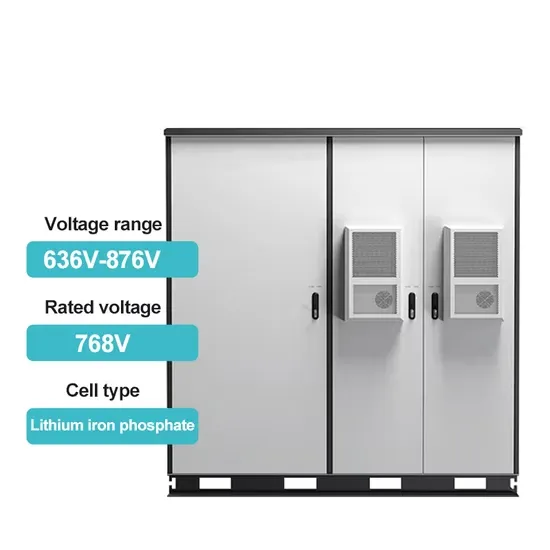

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.