UPS / DC Equipment and Battery Rack, Installation and

3 days ago · Follow the battery installation diagram and manual for installation. Wipe dust off battery terminals and check that each bolt is tightened before installing connection bars.

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · Calculating Cabinet Height Chargers need room to breathe and batteries need extra room above for maintenance (watering and testing). To calculate the minimum height of

Maintenance BestPractices & Intervals for Substation

Oct 24, 2017 · Maintenance BestPractices & Intervals for Substation Equipment Presented by: Paul Schlies, President/CEO Energis High Voltage Services, Inc.

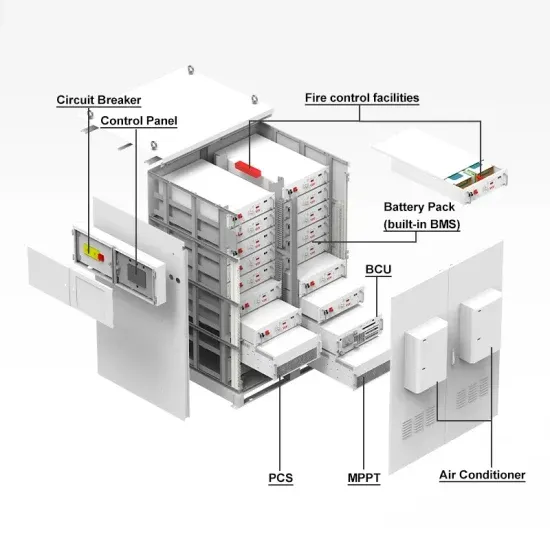

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Designing Industrial Battery Rooms: Fundamentals and

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

MS For Battery Installation | PDF | Electrical

Nov 18, 2024 · By adhering to these quality control measures, the substation can ensure the reliable and safe operation of the battery installation, minimizing

Auxiliary DC Control Power System Design for Substations

at make up the auxiliary dc control system are required. Many references for stationary battery sys-tem design address only a specific battery technology, making it difficult to compare

Substation Battery Systems Present & Future

Apr 29, 2024 · The substation batteries for the DC system must be in operation 24/7 – 365 – NOT just for backup power, but also to provide the current needed for day-to-day switching operations

Batteries and Battery Chargers in Major Substations

Jun 6, 2024 · Design Criteria - Batteries Design philosophy to ensure sufficient capacity to make safe substation on loss of AC supply. In addition the ability to supply high current transient

EAGLE EYE TECHNICAL NOTE

Apr 26, 2025 · The battery model numbers, date codes, batch numbers, installation date, and other pertinent information should be clearly visible or available on site. The cell/unit numbers

The BESS System: Construction, Commissioning,

3 days ago · The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various

Understanding the Essential Site Requirements for Battery

Nov 19, 2024 · Whate are the key site requirements for Battery Energy Storage Systems (BESS)? Learn about site selection, grid interconnection, permitting, environmental considerations,

6 FAQs about [Substation battery cabinet installation site]

What are the requirements for a substation battery system?

Substation battery systems shall be dedicated to connected DC load and shall not be part of a plant UPS or other DC system. Working space of at least 1 meter shall be provided in front of each battery rack or enclosure. Batteries shall be supplied with covers for all inter-cell connecters and terminals or insulated copper busbars to enhance safety.

How to install a battery cabinet?

Check the battery cabinet placement against the construction drawing. Ensure there is maintenance space and a distance of more than 0.5 meters from heat sources. Follow the battery installation diagram and manual for installation. Wipe dust off battery terminals and check that each bolt is tightened before installing connection bars.

Where should a stationary battery be installed?

Stationary batteries shall be installed on open battery racks within a battery room to facilitate proper cooling, routine inspection, and maintenance. Covers for all inter-cell connecters and battery terminals or insulated copper busbars shall be supplied as part of the battery to enhance safety.

Why do substations need reliable energy storage solutions?

With the power utility landscape changing in terms of both architecture and methods of generation, the need for reliable energy storage solutions is growing. Substations are evolving and adapting to support new and varied generation sources including renewables.

How do switchgear and substation power systems work together?

Switchgear and substation power systems work together to deliver electric power and reduce potential downstream faults ensuring safe electrical power. With the power utility landscape changing in terms of both architecture and methods of generation, the need for reliable energy storage solutions is growing.

How to install a battery?

Batteries are pre-charged before leaving the factory. Wrap all metal installation tools with insulating tape to prevent short circuits. Maintain a gap between batteries during installation for good heat dissipation. Clarify the installation method and load-bearing conditions before starting. 2. Installation Steps

Learn More

- 32 battery cabinet UPS installation site

- 24 UPS battery cabinet installation site

- Addis Ababa Street Site Energy Battery Cabinet

- Is there a site energy battery cabinet in Bucharest

- How to view distributed power generation at the battery exchange cabinet site

- Solar cell cycle energy storage cabinet installation site

- How much does a site energy battery cabinet cost

- About UPS lithium battery site cabinet

- 2 sets of 18 battery cabinet installation

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.