Cell geometry influences on the vibration performance of

Feb 15, 2025 · This study uses the International Electrotechnical Commission standard (IEC62660–2) to investigate the performance of pouch, cylindrical, and prismatic lithium-ion

Impacts of vibration and cycling on electrochemical

May 1, 2024 · This study investigates the alterations in the electrochemical performance of batteries subjected to vibration at different frequencies and the changes in cyclic batteries after

Effects of vibrations and shocks on lithium-ion cells

Aug 15, 2015 · Therefore standard tests and real-world loads were used to stress lithium-ion cells. At first, standards for vibrations and mechanical shocks on cell level were listed and compared

Battery Mechanical Abuse – The big vibration test for EVs

Oct 27, 2023 · Random vibration, shock, and sinusoidal or sine sweep tests are the most common vibration tests for batteries. The main differences between the standards are the type of

Battery vibration test – an important part of

6 days ago · Electric vehicle power batteries are generally arranged in the lower body of the vehicle. The electric vehicle power battery is subjected to the

Comparative study of vibrational behaviour of lithium-ion batteries

Jun 1, 2025 · Abstract The impact of placement orientation on vibration-induced electrochemical degradation of three different lithium-ion battery geometries, namely, pouch, prismatic, and

Microsoft PowerPoint

Apr 20, 2009 · Cells and batteries are firmly secured to the platform of the vibration machine without distorting the cells in such a manner as to faithfully transmit the vibration. The vibration

The Ultimate Guide to Vibration Testing for EV Battery Packs

Sep 11, 2024 · Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep

Energy storage battery cabinet vibration standard

Energy Storage System Basis: What Are Energy Storage Cabinet GB/T36276-2018 "Lithium-ion batteries for electric energy storage": This standard applies to lithium-ion batteries used in

Spectral analysis of sine-sweep vibration: A fatigue damage estimation

Aug 1, 2021 · To this aim, the task of this research is to propose a method, entirely in the frequency domain, for the estimation of the fatigue life of mechanical components subjected to

Electromagnetic Vertical+Horizontal Test Bench/Vibration

Aug 17, 2025 · Products Description Electromagnetic Frequency-sweep Vibration Test bench is suitable for low frequency vibration test of samples in labs and production lines such as

Spectral analysis of sine-sweep vibration: A fatigue damage

Aug 1, 2021 · To this aim, the task of this research is to propose a method, entirely in the frequency domain, for the estimation of the fatigue life of mechanical components subjected to

Grid-Connected Off-Grid Lithium Iron Phosphate 1075.2KWH battery

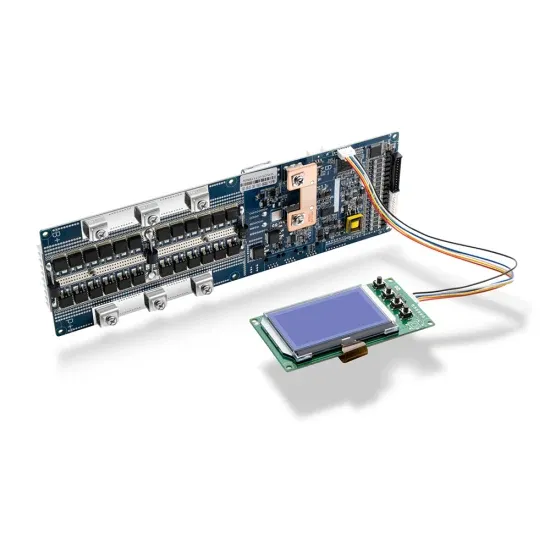

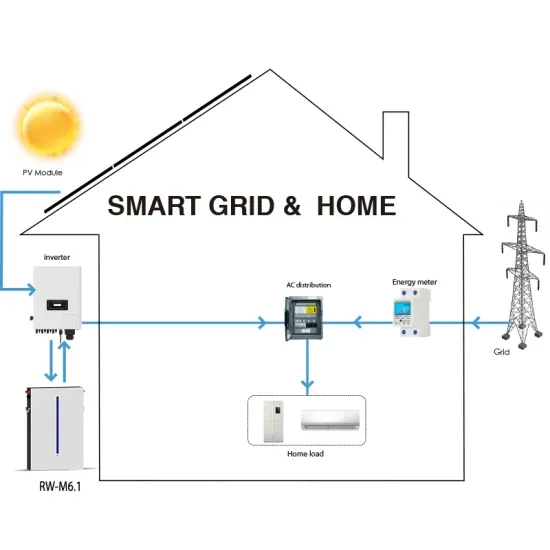

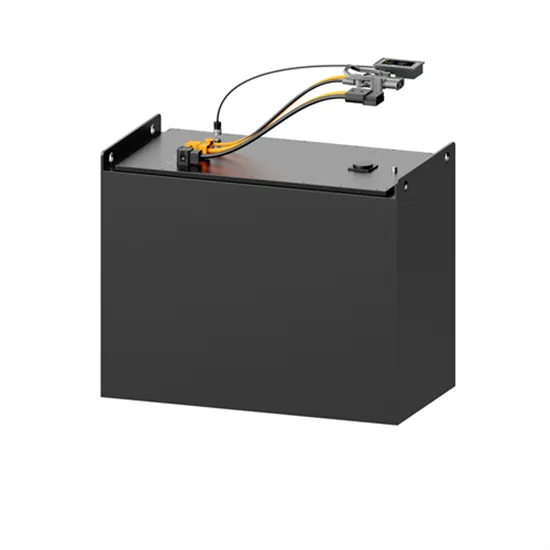

Lithium Battery Cluster The main components of battery energy storage solutions system consist of a battery module formed by safe, high-efficiency, long-life lithium iron phosphate cells

SHOCK AND VIBRATION RESPONSE SPECTRA COURSE

Jul 25, 2012 · SHOCK AND VIBRATION RESPONSE SPECTRA COURSE Unit 3. Sine Sweep Frequency and Octave Calculations By Tom Irvine Introduction A common specification for a

Narrow-band random vibration test example with frequency sweep

JIS C 7506-2 (IEC 60810) "Lamps for road vehicles-Performance requirements"- Part 2: Performance requirements" describes the items for evaluating vibration resistance and the test

(PDF) An Overview of the Impact of Vibrations on Li‐Ion Battery

Jun 16, 2025 · This study uses the International Electrotechnical Commission standard (IEC62660-2) to investigate the performance of pouch, cylindrical, and prismatic lithium-ion

High voltage lithium battery cabinet 51.2KWh--SHENZHEN

High voltage lithium battery cabinet 51.2KWh--SHENZHEN iYPOWER CO., LTD pyright © 2016 Dongguan Aiyang Power New Energy Co., Ltd. All rights reserved 粤ICP备

6 FAQs about [Battery cabinet vibration 2 2KWH sweep frequency]

What is sweep frequency vibration?

Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep speed. The frequency change in linear sweep is linear, meaning it covers a certain number of hertz per unit time, expressed in Hz/s or Hz/min.

Does sine sweep vibration affect battery capacity?

Brand et al. applied the UN38.3 T3 standard to subject batteries to sine sweep frequency vibration. The study revealed that after 10 cycles of sine sweep frequency, the battery capacity under Z-axis vibration did not exhibit significant degradation, while the mandrels experienced loosening.

What is the difference between fixed frequency vibration and sweep frequency vibration?

Fixed-frequency vibration is mainly used to test the resistance to resonance frequency vibration and predetermined frequency vibration. Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep speed.

What are the different types of vibration tests for batteries?

Here is a list of some of the standards for vibration testing Random vibration, shock, and sinusoidal or sine sweep tests are the most common vibration tests for batteries. The main differences between the standards are the type of excitation, the vibration profiles, and the frequency range.

What are vibration test profiles for lithium-ion batteries?

Vibration test profiles for lithium-ion batteries typically include sine sweep and random vibration tests. These profiles help simulate real-world conditions to ensure the battery’s durability and reliability.

What are the standards for vibration testing of battery systems?

Most testing standards for battery systems include vibration tests. The national mandatory standard GB38031 ⇱, issued in 2020, clearly defines the methods and requirements for vibration testing of power battery systems. The relevant standards for vibration testing of battery systems in both domestic and international contexts are as follows:

Learn More

- Battery cabinet flip 2 2KWH device

- Battery cabinet vibration table

- Battery cabinet factory direct sales

- Slovenia communication base station flow battery cabinet

- Costa Rica outdoor communication battery cabinet customized integrated system

- Battery cabinet price latest

- Battery cabinet new energy base station power generation

- 5kups with battery cabinet

- How to measure the capacitive coupling of the battery cabinet

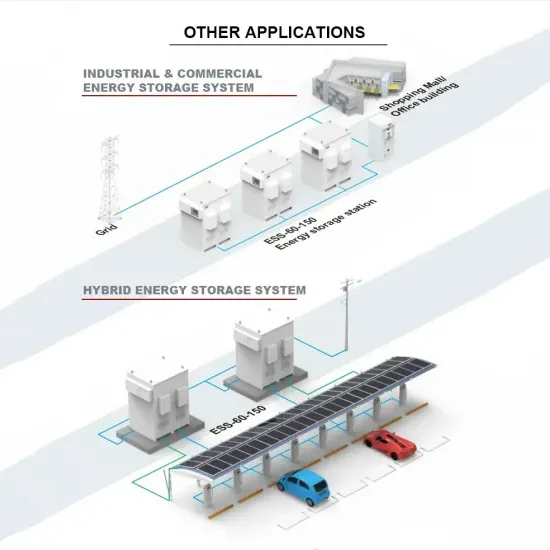

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.