Flash-Split: 2D Reflection Removal with Flash Cues and

Dec 31, 2024 · Abstract Transparent surfaces, such as glass, create complex reflections that obscure images and challenge downstream computer vision applications. We introduce Flash

Three-dimensional printing of multicomponent glasses using

Nov 11, 2019 · Here, we report a digital light-processing 3D printing platform that exploits the photopolymerization-induced phase separation of hybrid resins to create glass parts with

Aalborg Universitet Double glass transitions in phase

C occurs in the primary glass phase, while the second glass transition with a Tg value of around 410 °C appears in the second phase. The second glass transition bec mes more pronounced

Mixed matrix membranes for selective gas separation of H

Apr 1, 2025 · Mixed matrix membranes for selective gas separation of H2/CH4 and CO2/CH4 via fabricating high-performing double-ligand ZIF-8 with cellulose acetate-based polymer

PABCO Gypsum Area Separation Wall Systems (ASW)

May 24, 2023 · The key component of the H-Stud ASW is a continuous double layer of 1-inch thick, Type X, non-combustible PABCORE® Shaftliner or PABCO GLASS® Shaftliner panels

Components Separation Technique Combined with a Double

The components-separation technique in combination with a double-mesh has shown a low recurrence rate in the short-term follow-up. However, there is a considerable occurrence of

Progress in Separation Technology for Retired

Jan 1, 2025 · Download Citation | Progress in Separation Technology for Retired Photovoltaic Modules and Suggestions for Recycling | With the "double carbon" target and energy structure

Technical Guide: Area Separation Walls (DensGlass®

Sep 2, 2024 · DensGlass® Shaftliner is a unique area separation wall panel and a key component of an Area Separation Wall assembly for use in multi-family townhouses. DensGlass Shaftliner

Formation and phase evolution of liquid phase-separated

Sep 1, 2016 · The quaternary Zr-La-Co-Al phase-separated metallic glasses (MGs) are shown to experience double glass transition, crystallization and melting events, which could be regarded

Phase separation in metallic glasses

Oct 1, 2013 · The metallic glass systems which include an atom pair with large positive enthalpy of mixing decompose by liquid–liquid phase separation separate in the liquid state, forming two

Regulating Biocondensates within Synthetic Cells via

Apr 28, 2025 · Living cells orchestrate a myriad of biological reactions within a highly complex and crowded environment. A major factor responsible for such seamless assembly is the

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

Transformation of Highly Stable Two-Component Glasses

Jun 11, 2025 · Physical vapor deposition (PVD) is a method of glass formation in which molecules utilize enhanced mobility at the free surface to reach highly equilibrated amorphous states.

The Typology of the Double Skin Façade System | SpringerLink

Sep 26, 2023 · The double envelope system realizes the diagonal passive ventilation through the integrated and functional constitution of two contiguous components, laterally enclosed by the

Step by Step Technical Manual of Blood Components

Aug 15, 2025 · st effort to present my practical knowledge regarding blood component preparation. The book covers all areas of the subject, i.e. selection of donors, safe handling of

Laser-guided vectorial etching of glass microstructures

May 1, 2025 · Precision machining of micro-structured glass components is crucial for numerous applications, yet conventional machining methods face challenges in achieving customizable

Physics Tutorial: Dispersion of Light by Prisms

The refraction of light at the entry location into the rectangular glass prism would cause a little separation of the white light. However, upon exiting the glass prism, the refraction takes place

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

6 FAQs about [Double glass component separation]

Does a polymeric material exhibit a phase separation-induced glass transition?

In this study, we report on a polymeric material synthesized from a blend of a high Tg polymer and a plasticizer, exhibiting a phase separation-induced glass transition around the upper critical solution temperature (UCST).

Can phase separation be used to fabricate complex glass parts?

Analogously to conventional porous glass fabrication methods, we exploit phase separation phenomena to fabricate complex glass parts displaying light-controlled multiscale porosity and dense multicomponent transparent glasses with arbitrary geometry using a desktop printer.

How does phase separation occur in metallic glasses?

From this point of view, phase separation in metallic glasses can occur by liquid–liquid separation during cooling from the liquid melts or by separation into two glasses in frozen-in glass during heating. Earlier reports on phase separation mostly deal with the latter type of phase separation.

Is three phase separation possible in metallic glass system?

As the temperature goes down, Ti-rich phase undergoes the phase separation in the (Ti–Al–Co)– (Y–Al–Co) pseudo-binary miscibility gap forming Y-rich phase in Ti-rich phase, which is referred to as a cascade reaction . Above mentioned example clearly demonstrates that three phase separation is possible in metallic glass system. Fig. 19.

How is phase separated metallic glass formed?

For the formation of phase separated metallic glass, liquid–liquid phase separation takes place first during cooling and then each liquid phase experiences glass transition at lower temperature. Considering that GFA and Tg are strongly dependent on the alloy chemistry, phase separated two liquid phases, in general, have different GFA and Tg.

Why is phase separation a problem in glass-ceramics?

Phase separation has often been a source of problems f or glass production (Morey, 1954). It modifies the deteriorating the quality of the final glass. However, the production of heterogeneous m aterials containin g phases of different nature and morphology can be considered an advantage in the field of glass-ceramics. The wide range of

Learn More

- Double glass light transmission component installation

- Double glass component broken

- South America Double Glass Module Price Per Watt

- Double glass components are lightweight

- Oslo double glass photovoltaic module price

- 9BB high efficiency photovoltaic double glass module

- Marshall Islands double glass photovoltaic curtain wall installation

- Color PVB high efficiency double glass components

- New Energy Photovoltaic Power Generation Glass Component Lamination

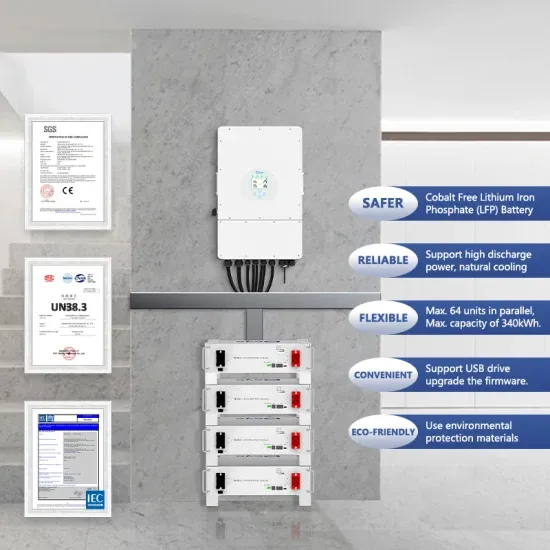

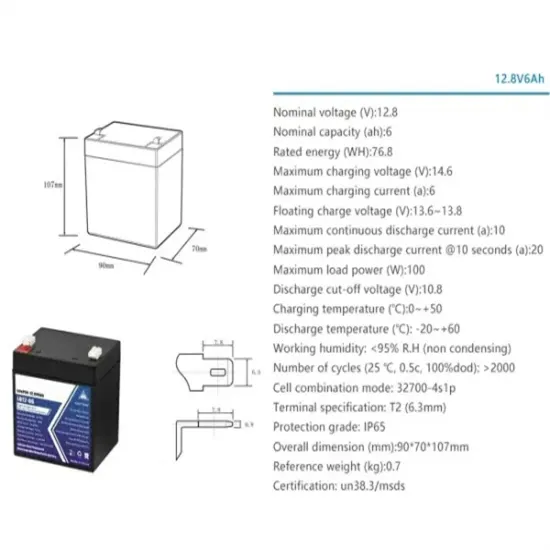

Industrial & Commercial Energy Storage Market Growth

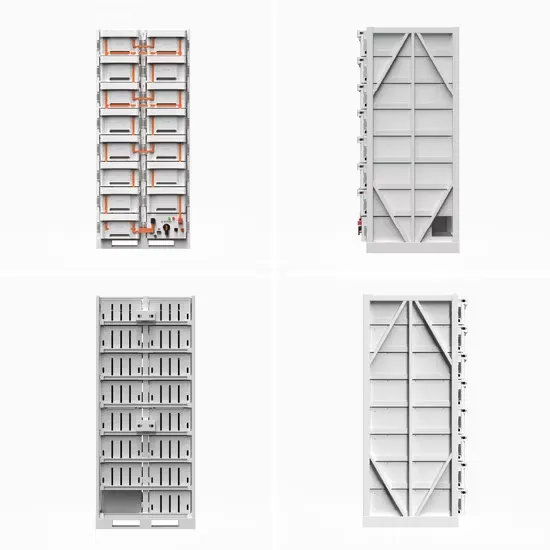

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.