PV Combiner Box: Ultimate Guide 2025 & ETEK Solar Solutions

4 days ago · Learn about types (600V, 1000V, 1500V, AFCI), how to choose the right one, and why PV Combiner Box excel in efficiency for solar systems.

PV Combiner Box: Ultimate Guide 2025 & ETEK Solar Solutions

4 days ago · A solar combiner box (or photovoltaic combiner box) consolidates multiple strings of solar panels into a single main output circuit. It acts as the "traffic controller" of your solar

Application and development trends of intelligent combiner boxes

With the advancement of technology, traditional combiner boxes are transforming into smart combiner boxes, which has significantly improved the efficiency, safety, and operation and

China Driven Quality PV Combiner Boxes for Global Buyers

Jul 10, 2025 · China Driven Quality PV Combiner Boxes for Global Buyers to Trust You know, in this fast-changing world of renewable energy, there''s really a big need for high-quality parts,

Solar Combiner Boxes – RAND Manufacturing Group – Solar

RAND PV Solar Combiner Boxes redefine the standard of solar technology by offering customized, innovative, and safety-conscious solutions for your specific solar installation''s needs.

Master Sourcing Photovoltaic Combiner Boxes for Optimal

Jun 16, 2025 · Unlock cost savings and reliability with our guide on photovoltaic combiner boxes, tailored for international B2B buyers in Egypt and Argentina.

Exploring the Future of Solar Energy in 2025 How the Best PV Combiner

Jul 29, 2025 · A key player in this transformation is the PV combiner box. This little component does a big job by boosting the reliability and performance of solar systems. As PV installations

Photovoltaic combiner box selection

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · Scalability: Supports larger systems by organizing multiple PV strings in a compact, manageable format. Common Types of Combiner Boxes Depending on the application and

PV String Combiners > Solar Combiner Boxes > EcoDirect

A solar combiner box combines multiple DC inputs from a solar array. It also improves overall safety and ease of installation. We offer both standard solar combiners and Midnite Solar''s

Exploring the Future of Solar Energy in 2025 How the Best PV Combiner

Jul 29, 2025 · As the solar industry evolves, the integration of innovative features into combiner boxes is enhancing system performance. A report by the National Renewable Energy

The Ultimate Guide to Solar Combiner Boxes:

Sep 26, 2024 · Solar combiner boxes are integral to solar power systems, serving to combine the outputs of multiple solar panel strings into a single output for

The fifth batch of photovoltaic combiner boxes bidding

Combiner boxes are vital in photovoltaic power generation, gathering and disbursing direct current (DC) generated from multiple photovoltaic panels to enable seamless connections to inverters

What Is a Combiner Box as Used in PV System

Jun 9, 2025 · By combining the DC inputs from several photovoltaic strings, the combiner box outputs a single DC feed to the inverter, reducing wiring complexity and enhancing system

6 FAQs about [The fifth batch of photovoltaic combiner boxes]

What is a PV combination box?

What is a PV Combiner Box? A PV Combiner Box is a device that brings together the output from multiple solar panel strings and channels it into a single output going to the inverter. It simplifies wiring, improves safety, and keeps your solar setup neat and manageable. In a typical solar power system, each string of panels generates DC electricity.

What is a solar combiner box?

Solar combiner boxes are essential components in solar photovoltaic (PV) systems, designed to consolidate the outputs of multiple solar panel strings into a single output for connection to an inverter. There are various types of combiner boxes tailored to meet specific needs and configurations in solar installations. Here are the primary types:

What is a PV AC combiner box?

The new PV AC Combiner boxes have been designed for PV systems with string inverters in trackers or fix tilt systems.The product portfolio is suitable for inverters from 60 kW up to 200 kW and support voltages of 400 V, 690 V or 800 V AC. The combiner boxes allow to collect from 2 up to 6 string inverters in one single cabinet.

Do you need a solar combiner box?

Adaptability: While smaller residential systems may not require a combiner box if they have only one to three strings, larger systems—ranging from four strings up to thousands—benefit greatly from their use. This adaptability makes combiner boxes suitable for both residential and commercial applications. II. Basics of PV Solar Combiner Boxes

Why should you choose LS solar combiner boxes?

As developed based on customers’ needs, LS’s PV combiner boxes provide optimum connections and protections from the modules to the inverters. High reliability and safety. Optimized for solar power plants. The enclosure was made of metal (SS304) to increase durability. It is designed based on the latest IEC standards and has been certified as CB.

How many string inverters can a combiner box collect?

The combiner boxes allow to collect from 2 up to 6 string inverters in one single cabinet. They withstand ambient temperatures from -20 up to +50°C to operate in hardest climate conditions, fulfilling the highest market standards as per IEC 61439-2 ed 3.0:2020.

Learn More

- What are the photovoltaic DC combiner boxes

- How many photovoltaic combiner boxes are there

- How many combiner boxes are used in a 500kw photovoltaic power station

- 1000v photovoltaic combiner box

- Nepal photovoltaic power generation combiner box recommendation

- Photovoltaic combiner box power supply

- Belize Photovoltaic Combiner Box Wholesale

- Nicosia Photovoltaic Combiner Box Wholesale

- Burundi 1500vdc photovoltaic combiner box

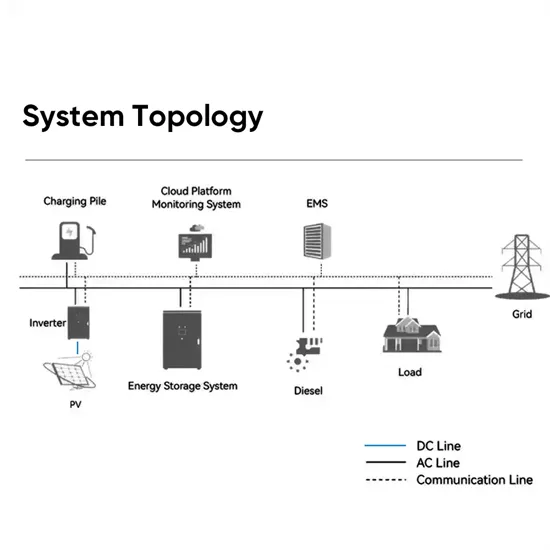

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.