A review of battery failure: classification, mechanisms, analysis

Battery failure analysis mainly includes experimental characterization and data analysis, and failure management mainly includes sensor measurement and dynamic management. At

WHITE PAPER BATTERY FAILURE ANALYSIS

Jul 19, 2024 · A failed nickel-cadmium battery The challenge of battery failure analysis is to unambiguously identify the problem''s root cause. Failure analysis involves the use and

Lithium battery failure classification and failure

Apr 29, 2022 · 1. Classification of lithium battery failure In order to avoid the above-mentioned performance degradation and battery safety problems, it is

Summary and Analysis of the Aging Aircrafts'' Failure

Jan 1, 2011 · Nowadays the Civil Aviation Authority calls for increasing safety level of the aging aircraft operation, and the maintenance problem was more prominent during the aging period

A review of lithium ion battery failure mechanisms and fire

Jul 1, 2019 · Lithium ion batteries (LIBs) are booming due to their high energy density, low maintenance, low self-discharge, quick charging and longevity advantage

The battery failure databank: Insights from an open-access

Mar 30, 2024 · The thermal response of Li-ion cells can greatly vary for identical cell designs tested under identical conditions, the distribution of which is costly to fully characterize

BESS Incidents

Mar 20, 2024 · Battery Failure Analysis and Characterization of Failure Types By Sean Berg October 8, 2021 This article is an introduction to lithium-ion battery types, types of failures, and

An exhaustive review of battery faults and diagnostic

Oct 1, 2024 · Various abusive behaviors and working conditions can lead to battery faults or thermal runaway, posing significant challenges to the safety, durability, and reliability of electric

Functional Hazard Assessment Aircraft Electrical System

The RSL aircraft electrical system has three electrical systems called the left power module, standby power module, and right power module. If all of these electrical systems fail, the

How batteries go bad: Understanding battery

Jan 8, 2025 · Batteries have become essential components of our infrastructure; they provide uninterrupted power to data centres and facilitate the integration

WHITE PAPER BATTERY FAILURE ANALYSIS

Jul 19, 2024 · 1. INTRODUCTION dentify the root cause of a failure. The findings from a failure analysis are often used to determine corrective actions such as to prevent the failure of similar

Reliability analysis of aircraft power system based on

To accurately analyze the reliability of the aircraft power system, first, this study adopts the α factor model to decompose the failure rates of the common failure components, and the...

Six Sigma Report: Boeing 787 Dreamliner Battery Issue

Sep 12, 2024 · The analysis focused on two major battery fire incidents that grounded about 50 aircraft globally. Six Sigma tools, such as Pareto charts, Fishbone diagrams, and histograms,

Failure analysis of power electronic devices and their applications

2 days ago · Power electronic devices are the core components of modern power converters, not only for normal applications, but also for extreme conditions. Current design of power

有道翻译_文本、文档、、在线即时翻译

有道翻译提供即时免费的中文、英语、日语、韩语、法语、德语、俄语、西班牙语、葡萄牙语、越南语、印尼语、意大利语、荷兰语、泰语全文翻译、翻译、文档翻译、PDF翻译、DOC

Analyzing Case Studies of Structural Failures in Aircraft Design

Jun 26, 2024 · Each aircraft structural failure case study serves as a learning opportunity, providing insights into engineering practices and regulatory measures that can enhance safety

Failure Analysis Case Study for Aerospace Industry

Sep 5, 2023 · The Failure Analysis (FA) team has conducted thorough analyses of more than 120 cases covering crashed helicopters, landing gears of passenger aircraft and different types of

BESS Write-up Failures and Forensics_SMB

Jan 17, 2024 · Battery Failure Analysis and Characterization of Failure Types By Sean Berg October 8, 2021 This article is an introduction to lithium-ion battery types, types of failures, and

Battery failure analysis and characterization of

May 19, 2022 · This article is an introduction to lithium-ion (Li-ion) battery types, types of failures, and the forensic methods and techniques used to investigate

Battery safety: Fault diagnosis from laboratory to real world

Apr 1, 2024 · Causes and mechanisms of battery faults and failures are concisely reviewed. The gap between lab tests and real-world battery safety is succinctly summarized. A cloud-based

6 FAQs about [Analysis of the reasons for power failure in the battery cabinet of passenger aircraft]

What are battery safety issues in electric aircraft?

Battery safety issues in the context of electric aircraft can be categorized into (1) thermal, which relates to the risk of excess heat, fire, and explosions; and (2) functional, which relates to loss of safety critical power due to material degradation or architectural or control-related malfunctions of battery systems.

What happens if an aircraft electrical system fails?

Abstract . The Aircraft electrical system used to supply electrical power for any systems such as navigation, communication, flight control, and others. The failure in the electrical system results in disruption of the supply of electrical energy which results in accidents and fatal accidents.

Why do avionics power systems fail?

The results of review of the technical failures due to the electronics shows that about 25% are attributed to the power system, and 36% of electrical failures represent interconnection errors, consisting of connectors and wiring problems . The current trend of avionics power systems includes switching power electronics.

What are the risk factors for batteries used in aviation?

One of the biggest risk factors for batteries used in aviation is the potential for thermal runaway where temperatures reach the flashpoint of one of the cell components, eventually cascading over multiple cells leading to system-wide battery pack failure and a fire hazard.

Why do lithium-ion batteries fail?

These articles explain the background of Lithium-ion battery systems, key issues concerning the types of failure, and some guidance on how to identify the cause(s) of the failures. Failure can occur for a number of external reasons including physical damage and exposure to external heat, which can lead to thermal runaway.

What are the Future Perspectives on battery failure?

Future perspectives are provided, covering materials, cells, and system levels. Battery failures, although rare, can significantly impact applications such as electric vehicles. Minor faults at cell level might lead to catastrophic failures and thermal runaway over time, underscoring the importance of early detection and real-time diagnosis.

Learn More

- Battery cabinet new energy base station power generation

- How to view distributed power generation at the battery exchange cabinet site

- Is the new energy battery cabinet AC power

- Battery cabinet base station power method base station

- Battery cabinet production module site power supply

- Battery cabinet base station power panel

- Kazakhstan new energy battery cabinet base station power

- Battery cabinet adjustable power supply charging

- Tiraspol outdoor communication battery cabinet power

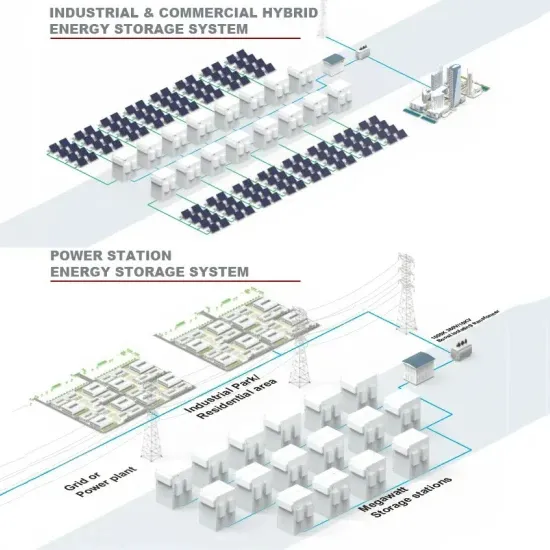

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

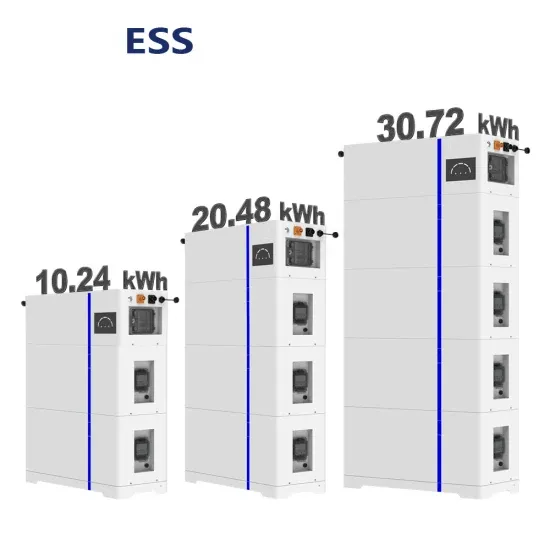

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.