Chapter 5: Communication Flashcards | Quizlet

Oct 4, 2024 · Study with Quizlet and memorize flashcards containing terms like base station, Where should base stations be located?, What are components of an Emergency

Energy Management Systems (EMS): Architecture, Core

Jan 25, 2025 · Energy Management Systems (EMS) play an increasingly vital role in modern power systems, especially as energy storage solutions and distributed resources continue to

EMS chapter 5 questions 1-25 Flashcards | Quizlet

Mar 10, 2025 · Study with Quizlet and memorize flashcards containing terms like The purpose of a communications system is to:, Which of the following statements regarding a base station is

Design Considerations and Energy Management System for

Jun 20, 2024 · This paper presents the design considerations and optimization of an energy management system (EMS) tailored for telecommunication base stations (BS) powered by

Enhancing BESS Efficiency with Advanced EMS: Features,

Sep 28, 2024 · Discover how an advanced Energy Management System (EMS) optimizes Battery Energy Storage Systems (BESS) through centralized monitoring, intelligent control, and

Design Considerations and Energy Management System for

Jun 20, 2024 · This paper presents the design considerations and optimization of an energy management system (EMS) tailored for telecommunication base stations (BS) powered by

Mastering EMS Communication: The Essential Role of Base Station

Understanding the vital requirements for EMS communication, particularly the significance of a base station''s height, is crucial for anyone preparing for the North Carolina EMT State Exam.

Intelligent Telecom Energy Storage White Paper

Jul 7, 2023 · Dual-network integration and cloud-network synergy, The the energy flow through the information flow. The cloud network is linked together to implement intra-stati n and out

6 FAQs about [Can the EMS power of a communication base station be adjusted ]

How does EMS work?

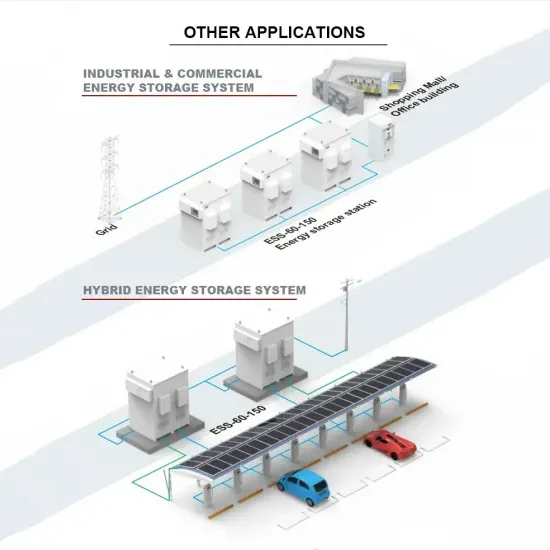

The configuration of EMS depends on the type and requirements of the storage system. Here are two common configurations: In this configuration, the photovoltaic system provides green electricity to the load. When solar radiation is insufficient, the system automatically switches to the grid or diesel generator to supplement the energy supply.

How can EMS improve the performance of a storage system?

EMS can automatically adjust the charging and discharging strategy of the storage system based on the operating status of the grid, power demand, and the supply capabilities of different energy resources (such as photovoltaic, wind, diesel generators, etc.), thus enhancing the overall performance and economic benefits of the system.

How do EMS and BMS work together?

The two systems work together: EMS is responsible for the overall optimization of energy, while BMS focuses on the internal management and health monitoring of the battery. In a complete BESS, BMS provides the battery’s operating status information, and EMS uses this data to optimize the entire storage system’s charging and discharging strategy.

What is Energy Management System (EMS)?

With the increasing global demand for clean energy and smart grid technologies, BESS have gradually become an important component in the energy sector. To improve the efficiency and economic benefits of battery storage systems, the Energy Management System (EMS) has emerged.

What is a battery management system (EMS)?

It converts electricity between alternating current (AC) and direct current (DC), facilitating the charging and discharging of the battery. Energy Management System (EMS): The EMS is the brain of the operation. It monitors energy flows, decides when to store or release energy, and ensures optimal performance of the entire system.

What is Power Conversion System (PCS) and Energy Management System (EMS)?

Power Conversion System (PCS): Think of the PCS as the translator. It converts electricity between alternating current (AC) and direct current (DC), facilitating the charging and discharging of the battery. Energy Management System (EMS): The EMS is the brain of the operation.

Learn More

- Communication base station EMS photovoltaic power equipment

- Lima Communication Base Station EMS Hybrid Power Supply

- Bhutan communication base station lead-acid battery power generation

- Construction of solar photovoltaic power station for communication base station

- Liechtenstein communication base station wind power cooling chassis

- Uninterruptible power supply battery for communication base station

- Communication base station 12v power module

- Power supply for photovoltaic power generation system of China-Europe communication base station

- Sophia Communication Base Station Uninterruptible Power Supply Storage Reason Query

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.